Condition-Based Maintenance

Condition-based maintenance (CBM) is an approach to asset management that involves monitoring health and performance to proactively schedule maintenance work and optimize the lifetime value of critical equipment.

What is Condition-Based Maintenance?

Condition-based maintenance (CBM) is an advanced strategy for asset management that involves monitoring critical pieces of equipment to proactively identify and address signs of potential failure. The goal is to ensure maintenance teams can issue work orders and schedule maintenance activities right on time instead of following a fixed schedule or relying on costly corrective maintenance.

Table of Contents

- What is Condition-Based Maintenance?

- Pros and cons of a condition-based maintenance strategy

- How does condition-based maintenance management work?

- Examples of condition-based maintenance

- 7 steps for implementing condition-based maintenance programs

- Condition-based maintenance vs. predictive maintenance

- Is your organization ready for condition-based maintenance?

- Related Content

Pros and cons of a condition-based maintenance strategy

Like all proactive and preventive maintenance strategies, CBM offers a mix of benefits and drawbacks. Balancing these helps organizations keep their critical assets operational and minimize overall maintenance costs .

Benefits of CBM

Maintenance departments who successfully make condition monitoring a component of their equipment maintenance strategies can realize a host of benefits and better advocate for the maintenance function’s essential strategic value.

- Because CBM involves carrying out maintenance work while assets are still working, organizations can minimize unnecessary maintenance and avoid disruptions to their usual operations.

- Performing maintenance on an as-needed basis reduces the overall costs of completing maintenance work by ensuring maintenance teams aren’t scrambling to complete emergency repairs and minimize unplanned downtime .

- More proactive maintenance planning and scheduling improves resource allocation and spare parts inventory management, reducing the cost of overtime, total labor spend, and total spare parts spend.

- Avoiding breakdowns helps extend the lifespan of assets and improve their lifetime performance.

- More predictable maintenance schedules for and healthier assets reduce injury risks, resulting in a safer and more productive workplace.

The challenges and drawbacks of CBM

Introducing CBM isn’t for everyone. For some organizations, the upfront costs of implementing a condition-based strategy will outweigh the benefits. What’s more, CBM is a better fit for some assets than for others.

- Installing the equipment necessary for advanced condition monitoring is expensive. In some cases, you’ll need to invest in modifying assets or systems to accommodate new sensors. Older equipment, in particular, may present a wealth of challenges.

- Your maintenance staff will require specialized knowledge to take advantage of condition-monitoring equipment. Training your team will take time and money.

- Some operating environments cause damage to condition monitoring sensors and require costly replacements.

How does condition-based maintenance management work?

CBM programs combine a number of processes and solutions for assessing the condition of critical assets and managing them in the most cost-effective way possible.

Condition-based monitoring and maintenance tools

A handful of tools come together to power the data collection and analysis behind CBM.

- Condition-monitoring sensors: Installed directly on equipment, sensors can collect data in real time or based on an established schedule.

- Handheld condition monitoring tools: In addition to monitoring from sensors, CBM programs are supported by data collection through a range of portable tools.

- IoT technology: These tools transmit sensor data and other crucial information across your organization and integrated with essential maintenance software systems.

- Predictive data models and algorithms: Models and algorithms powered by machine learning analyze data to recognize and respond to anomalies.

Condition-based maintenance monitoring techniques

Along with simple visual inspections and non-destructive tests, different types of condition-based maintenance monitoring processes enable real-time data collection as part of CBM programs.

- Lubrication/oil analysis: Oil analysis involves measuring the viscosity of lubricants and analyzing contaminants to minimize wear and tear on machinery.

- Pressure analysis: Unexpected spikes or drops in pressure can have costly or even deadly consequences. Tools for analyzing pressure data in real time ensure that equipment containing fluid remains at the appropriate pressure to keep technicians and operators safe.

- Infrared thermography: This process involves the use of thermal imaging tools to collect baseline temperature data for equipment and monitor for signs of overheating.

- Ultrasonic analysis: This condition-based monitoring technique uses high-frequency sound waves to inspect materials for internal flaws, including corrosion, cracks, and other defects or potential causes of equipment failure.

- Vibration monitoring: Analyzing vibrations within rotating equipment, often using vibration sensors, can help identify common causes of asset failure like misalignment, deterioration, or imbalances.

- Electrical analysis: Abnormalities in the electrical currents flowing through machinery pose serious safety risks.

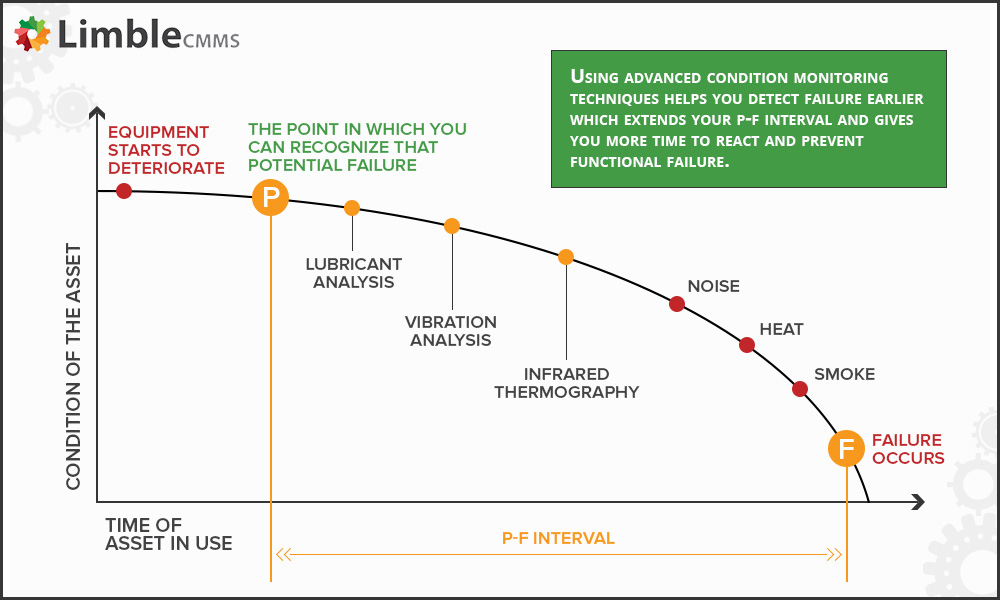

The P-F curve and the P-F interval

Prevention-Failure (P-F) curves are an essential part of any condition-based or reliability–centric program. Graphing these curves helps you assess the reliability and effectiveness of assets over time.

Point P marks the point at which you recognize the signs of a potential failure. Point F marks the point at which a functional failure will occur. Your P-F interval refers to the time between recognizing signs of a potential asset failure and experiencing one. A longer P-F interval is better. It means you’ve got plenty of time to carry out condition-based maintenance and avoid breakdowns.

Successful condition-based maintenance extends your P-F interval and keeps critical equipment in operational condition.

Successful condition-based maintenance extends your P-F interval and keeps critical equipment in operational condition.

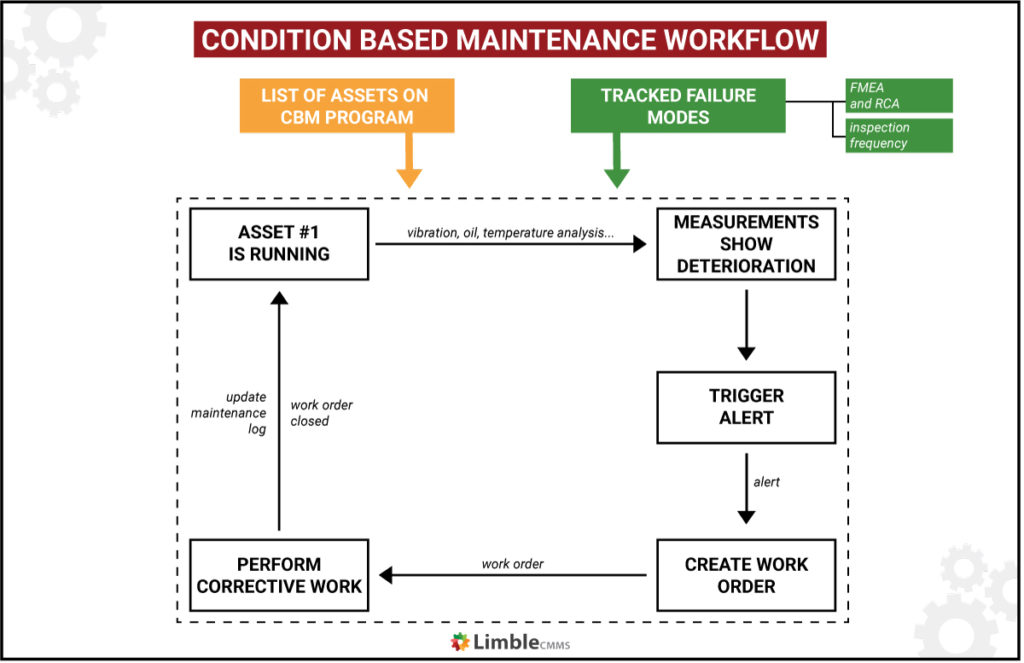

Condition-based maintenance workflow

The shape and complexity of the CBM workflow will vary from organization to organization and will even look different depending on the asset in question. A typical workflow looks like this:

- Sensors, inspections, and historical records support a thorough data collection process and streams this information to a central cloud-based location like a Computerized Maintenance Management System (CMMS).

- Algorithms help CBM software analyze an asset’s performance against baseline performance standards.

- Maintenance personnel receive automated alerts when equipment performance data deviates from acceptable levels.

- A work order is created and assigned to the appropriate technicians.

- Once the maintenance task is completed, technicians close the work order and update the maintenance log accordingly.

Over time, as you continue to collect data, your algorithms will grow and improve their predictive capabilities. You’ll get better and better at keeping uptime high by preemptively scheduling maintenance actions.

The typical workflow for assigning and completing work orders as part of a condition-based maintenance program.

The typical workflow for assigning and completing work orders as part of a condition-based maintenance program.

Examples of condition-based maintenance

Here are just a few examples of how CBM diagnostics and techniques help organizations manage their critical assets.

- A food and beverage manufacturer may leverage CBM to proactively monitor pressure levels within pipes and respond to avoid potential leaks. This helps prevent contamination, product loss, and costly downtime while ensuring compliance with safety regulations. For example, sensors can continuously monitor pressure and trigger alerts if deviations from normal operating ranges occur, enabling timely intervention to prevent leaks or ruptures.

- Automotive manufacturers can use vibration analysis to test the integrity of the bearings and rotors inside the motors they produce. By analyzing vibration patterns, they can identify early signs of wear, imbalance, or misalignment, allowing for proactive maintenance or replacement of components before they cause motor failure. This helps ensure the quality and reliability of their vehicles while minimizing production delays.

- Thermographic investigations can help facilities managers assess their HVAC systems to identify issues such as overheating components, inadequate insulation, or airflow restrictions. Thermographic cameras can detect temperature variations that indicate inefficiencies or malfunctions, such as air leaks, insulation problems, or overheating components. This allows for targeted repairs and improvements, optimizing energy efficiency and reducing maintenance costs.

7 steps for implementing condition-based maintenance programs

Here are some steps for introducing CBM to your organization and evolving your approach to asset management with data analysis .

- Define the scope of your program and set goals : Why are you looking to transition to CBM ? Outlining the goals and key KPIs of your program will give you a definition of success and a process for achieving it.

- Conduct a criticality assessment : CBM isn’t a cost-effective choice for every one of your business assets. A criticality assessment can help you determine which assets are likely to experience costly failures and prioritize them accordingly.

- Apply the right condition-monitoring techniques : Your specific pieces of equipment and their common failure modes will dictate your choices of condition-monitoring software and hardware. An RCM analysis can help here.

- Collect baseline data and establish performance thresholds : An initial data collection process will help you define “normal” for each piece of equipment and set thresholds for signaling when maintenance is necessary.

- Implement data collection and analysis processes : Next, ensure you have systems in place for collecting and analyzing data on an ongoing basis. At a basic level, this should involve integrating your condition monitoring technology with your CMMS .

- Introduce new workflows and responsibilities : Train your team to effectively execute the new program, taking care to establish systems for implementing data-backed improvements.

- Monitor and improve your program over time : Over time, analyze your program’s impact. Is your maintenance team ’s performance improving? Are your assets more reliable and productive? Close data analysis will offer the answers and help you devise strategies for continuous improvement.

Condition-based maintenance vs. predictive maintenance

Condition-based maintenance (CBM) and predictive maintenance (PDM) share a number of similarities and rely on some of the same processes. They are, however, distinct strategies.

- Predictive maintenance typically relies more heavily on advanced data analytics and predictive modeling, whereas CBM focuses on monitoring real-time asset conditions to trigger maintenance actions

- In CBM programs , maintenance is scheduled based on condition indicators or performance thresholds. For example, sudden temperature spikes above a certain number of degrees may prompt action. Predictive maintenance programs see technicians respond to estimates about upcoming failures.

- When they’re employing CBM , organizations aim to improve their approach to maintenance by scheduling tasks just in time. Predictive maintenance allows for an extra level of proactivity.

Want to see Limble in action? Get started for free today!

Is your organization ready for condition-based maintenance?

Getting the most out of your maintenance department isn’t just about transitioning to more predictive processes. CBM may not be the right answer for meeting your maintenance needs. Ask yourself questions like these to assess your readiness for CBM, determine which assets will make good candidates for CBM, and prepare your team for success.

- Are you prepared to monitor and address your equipment’s most common failure modes?

- Can you integrate your new solutions and processes with existing systems?

- Is the CBM program scalable across your full portfolio of critical equipment?

If you’ve answered yes to all three, it may be time to introduce a condition-based maintenance strategy. Download our guide to transitioning away from reactive maintenance to learn more about making the team more proactive and productive.