Maintenance plays a crucial role in establishing smooth business operations at every facility. Businesses that can’t (or don’t want to) take care of their physical assets directly will outsource their maintenance work. And you can’t do that without signing some type of maintenance contract.

To understand what makes a good contract and how to negotiate one, we first need to discuss the ideal circumstances for outsourcing maintenance work. Let’s get started.

What is a service maintenance contract?

A service maintenance contract is a legal agreement between a company and a maintenance service provider. It specifies the terms and conditions of the agreement between the two parties. Maintenance contractors can be hired to perform a variety of different maintenance services, from general upkeep to specialized repairs.

Any details negotiated between the two parties will be specified in the contract. This will solidify the commitment of the service provider. More information on what to include in a contract is explained later in the article.

Why outsource maintenance?

Maintenance of equipment and facilities can be set up in four different ways:

- work performed by an in-house maintenance team

- work is done by OEM (Original Equipment Manufacturer) technicians

- all work is assigned to third-party maintenance contractors

- various combinations of the above three ways

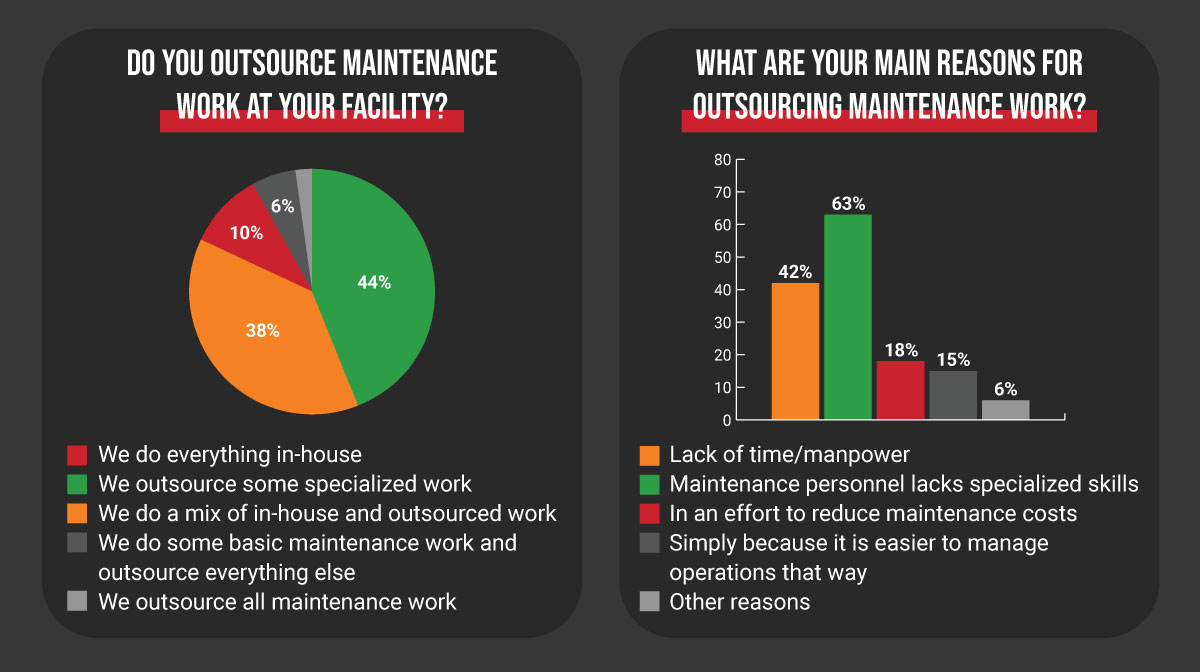

The only situation in which an organization won’t need to bother with maintenance contracts is if an internal team does all work. However, that is quite rare. According to our maintenance survey from February of 2021, only 10% of facilities do not outsource any maintenance work.

As is teased in the image above, the most common reasons to outsource maintenance activities are:

- there is just too much work for the internal team

- it makes no sense to keep a full-time employee for a specialized task that needs to be carried out occasionally (like hiring a full-time plumber)

- the organization lacks specialized knowledge or tools to perform certain repairs

- OEMs provide maintenance service as part of the sale of the equipment

- maintenance contractors could be more cost-effective

- the organization finds it simpler to just outsource everything

Each company will have its own reasons for engaging maintenance contractors. In such cases, a reliable maintenance contract is here to ensure a high level of service at a lower cost.

Types of long-term maintenance contracts (AMC vs CMC)

There are two main types of long-term maintenance service agreements called AMC and CMC.

AMC stands for an annual maintenance contract. CMC is an acronym for a comprehensive maintenance contract. They are used for hiring independent service contractors for any type of maintenance work – from landscaping and building maintenance to maintenance of machinery and IT equipment.

Both AMC and CMC cover the service charges for regular ongoing maintenance and emergency repairs. When an asset breaks down, the maintenance contractor will dispatch service personnel immediately. They will repair it and replace the spare parts (if needed).

An annual maintenance contract is a great way to cover basic maintenance needs, while a comprehensive maintenance contract covers any additional replacement parts, labor, or transportation costs that come up while technicians are performing routine maintenance. Annual maintenance services do not cover additional expenses that might come up during the maintenance process.

In short, AMC has a lower initial cost but can result in additional charges. CMC costs more, but there are no additional invoices to pay.

Maintenance Acronym Guide

Confused by PMs, MTTR, and DFMEA? This maintenance acronym guide will have you talking the talk in no time.

Length of a contract

Generally, the term for a service maintenance contract is one year. This holds true for both AMC and CMC. If the client-vendor relationship is going strong, they can be longer (3-year and 5-year maintenance contracts are not that uncommon).

Long-term contracts benefit both the company and the maintenance contractor. Some benefits for the company are:

- Quality control: The maintenance contractor will maintain assets on a regular basis. Since the contract is long-term, the contractor has the incentive to keep the machine well run. This leads to fewer breakdowns and an improved bottom line.

- Increased lifespan and performance: The long-term contract ensures that the machine is regularly serviced, increasing its lifespan and improving its overall performance.

- Peace of mind: Managing maintenance operations is a lot of work. Having a reliable contractor means the organization has one less thing to worry about.

- Cost benefits: Contractors offer a discounted price for long-term contracts. This can help reduce the annual maintenance cost without hampering the service level.

Maintenance vendors also prefer long-term maintenance contracts. If they can build strong relationships with existing clients, they ensure regular income, which is always nice. They have an incentive to provide a satisfying service to improve their brand reputation and get valuable recommendations.

Pricing methods

The price of a maintenance contract depends upon a lot of factors like the range of services, the maximum amount of breakdowns that need to be serviced, the number of assets, and contract length.

Different maintenance contractors will offer different pricing methods. They are usually negotiated between the vendor and the service provider to see what works for both. The most common ones are:

- Time-based pricing: The contract specifies a fixed hourly rate and is calculated according to the total number of man-hours the vendor spends.

- Per device pricing: The vendor and the company agree upon a fixed price for servicing a single device for the duration of the contract. To obtain the total price, multiply the price per-device by the number of devices covered under the contract.

- Pricing based on asset lifetime: As a machine gets older, the need for maintenance increases. The vendor might look to increase the pricing for such assets.

- Replacement vs repair: Should a vendor repair or replace certain assets/components when they break? The price of the contract can change depending on how the organization wants to handle this.

The contract can have other specific requirements from the client that will carry an additional cost. The terms, conditions, and the final price of the contract heavily depend on the negotiations between the two parties.

Maintenance managers and facility managers that are in contact with the vendors should have the skills and knowledge to negotiate a good maintenance contract. Here are a few useful tips for negotiating better terms.

What is included in a maintenance contract?

A service maintenance contract will usually contain the following details:

- Name and contact: The contract needs to have details like names of both the businesses, their registered address, details of signatories, and the location(s) where service is expected.

- Equipment details: Technical specification, location, operating conditions, and other relevant information regarding the machine to be serviced.

- The extent of responsibilities of the service provider should be clearly defined to avoid ambiguity in the future.

- Expectations from the client: The contractor cannot complete the tasks if the company and its workers are not cooperative. The contract will also have details of what the contractor expects from the client.

- Response time: The contractor is expected to offer service as soon as possible. The maximum response time, especially for critical assets, has to be clearly defined. Any response time beyond that is a breach of contract.

- Service completion time: The contractor needs to complete the service within a reasonable time frame. The contract should outline these stipulations.

- Compensation: In case the vendor damages the equipment or other property. Delay in service can also warrant compensation if it is specified in the contract.

- Price. The contract will clearly mention the price of the contract, the duration, and the terms of payment.

- Force majeure. This is the part of the contract that liberates both the parties of their obligations in the event of extraordinary circumstances. It is a standard in all legal contracts.

Beyond these, anything negotiated by the company and contractor can be added to the service contract.

How to write maintenance contracts

There is no hard and fast rule on how to write maintenance contracts. The most important thing to keep in mind is that the contract is enforceable by legal means. Well thought out terms and conditions should be a given.

The specifics of the contract will differ depending on the circumstances, the rules of the country, and customs of the place.

You can take a quick look at this guide that outlines how to write a basic maintenance contract. To see how they look in practice, you can refer to the templates listed below.

Common maintenance agreement templates

A company can create a maintenance contract for a specific purpose or by bundling all maintenance requirements. You don’t have to reinvent the wheel for every new contract. There are many resources and templates out there that can serve as a great starting point in creating a new contract:

- Equipment maintenance contract template

- HVAC maintenance contract

- Building maintenance contract template

- IT maintenance contract template

- Preventive maintenance contact

- Home maintenance contract template

While templates are great, the companies hiring independent maintenance service providers should carefully consider their specific needs and include them in the final maintenance agreement.

Using Limble CMMS to manage maintenance agreements and vendors

To wrap things up, let’s discuss how organizations can efficiently deal with vendors and contracts. By that, we mean having quick access to necessary information and the ability to track if the work performed by the vendor matches what was agreed upon in the contract.

Typically, maintenance managers have to deal with two types of vendors:

- those providing maintenance services

- those they purchase spare parts and materials from

Modern maintenance software like Limble CMMS can streamline the tracking and managing of any vendor. We will focus on contractors as it is the topic of this article.

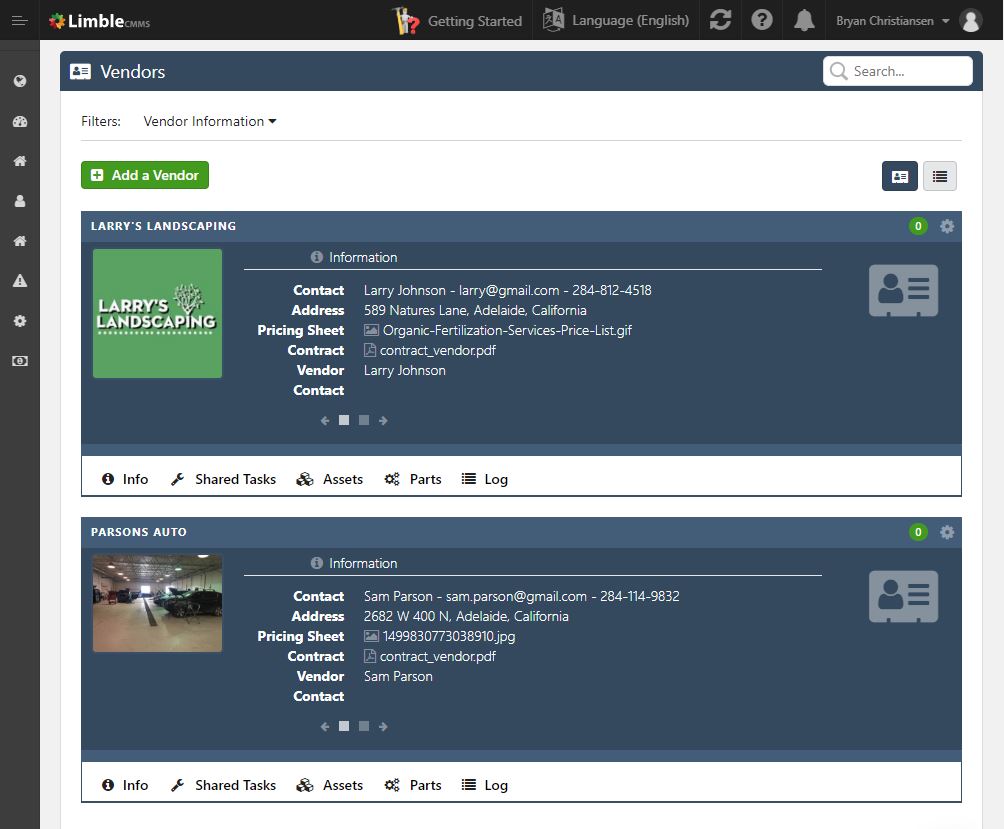

Aside from the maintenance agreements themselves, managers should have quick and easy access to other vendor information like names, addresses, emails, and phone numbers. This might seem trivial at first, but it is very helpful when you have contracts with multiple vendors and oversee multiple locations.

The image below shows how Limble keeps all vendor information in a centralized location:

If you look closer at the image, you will see that Limble lets you associate vendors with assets they maintain.

To streamline communication, companies can give maintenance contractors limited access to Limble software. Work orders can be sent directly to the vendor through our software (see how this works in practice here). The vendor receives the WOs and attached work instructions, performs the work, enters time and spare parts used, and closes the work order.

This way, maintenance and facility managers have a clear record of a vendor’s time, parts used, vendor invoices, and other desired data. They can use that data to generate reports and track how much money they are spending on specific vendors.