Mean Time Between Failure (MTBF)

Learn all about Mean Time Between Failure (MTBF), an essential metric for maintenance managers.

What is Mean Time Between Failure (MTBF)?

Mean Time Between Failure (MTBF) is an essential metric for maintenance management that measures the reliability of assets. It focuses on the average time a piece of equipment or particular system remains in operational condition before experiencing a failure. Alongside Mean Time to Repair (MTTR), the metric also measures asset availability.

Assets with low MTBF values are especially reliable and likely to be available when you need them. High-MTBF assets, on the other hand, are prone to unexpected outages. Tracking MTBF alongside other key metrics is essential for managing an effective preventive maintenance program.

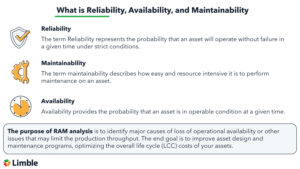

Reliability, availability, and maintainability

As part of a proactive maintenance strategy, MTBF and other metrics help reliability engineers and their teams better understand the reliability, availability, and maintainability of their assets.

- Reliability: The likelihood that a piece of equipment will work as needed under specific conditions over a specific period of time. For repairable assets, reliability is typically expressed in terms of MTBF.

- Availability: Similar to reliability, this measures the likelihood that an asset will work when you need it to. You’ll see maintainability expressed as a percentage of uptime across a given period.

- Maintainability: Measured primarily through MTTR, maintainability describes how easily your team can perform maintenance and repairs on assets.

How does tracking reliability, availability, and maintainability contribute to effective asset management?

Why is MTBF important?

Reliability analysis helps manufacturers take a more proactive approach to maintenance. It points out potential problems before they occur to ensure maintenance tasks are planned and scheduled to avoid failure. This minimizes unplanned downtime and mitigates the related costs. Ultimately, it helps contribute to an effective maintenance strategy.

Benefits of improving MTBF

- Improve the reliability of your assets: Focusing on improving the MTBF of critical assets makes them more reliable. This will decrease downtime and increase your organization’s productivity.

- Increase the lifespan of your assets: The insights provided by MTBF calculations make it possible to proactively address performance concerns and keep assets operational longer.

- Reduce overall maintenance costs: By enabling the shift to more proactive maintenance processes, tracking MTBF reduces the total cost of maintaining assets.

- Boost quality control: Dependable assets mean fewer product defects and, ultimately, more satisfied customers.

- Create a safer work environment: Improving the reliability and maintainability of your assets reduces the likelihood of unexpected breakdowns that could lead to accidents and injuries.

- Compare equipment for strategic purchasing: Over time, calculating MTBF makes it possible to compare and contrast the performance of different models of the same kinds of equipment. When it’s time to purchase replacements, you’ll confidently make more cost-effective decisions.

How to calculate MTBF

If you’re collecting the right data about your assets, calculating MTBF is simple. All you’ll need to know about the asset is its total operating time and how many times it has failed.

MTBF Formula

The formula for MTBF calculations involves dividing an asset’s total uptime by the total number of failures it has experienced across that timeframe. The types of failures you should include

Remember, the MTBF formula doesn’t account for scheduled downtime for routine maintenance or repairs. MTBF calculations also don’t provide any details on the root cause or severity of failures. It is just one component of reliability analysis and asset management.

MTBF calculations help you assess the reliability of your equipment.

Challenges for calculating MTBF

Though Your maintenance team may run into obstacles while you attempt to calculate MTBF:

- Lack of data: As noted above, accurate MTBF calculations require reliable data relating to uptime and the failures experienced across an asset’s service life. If you don’t have everything you need, you’ll struggle to achieve accurate figures.

- Complexity: Multi-component systems can make it challenging to pinpoint the source of failure and make the necessary calculations.

- Scheduled maintenance: Your schedule for maintenance tasks can impact the accuracy of your MTBF calculations. If lubrication and other routine maintenance occurs too regularly, you may not have enough failure data to calculate MTBF. If maintenance occurs too infrequently, MTBF figures may appear artificially low.

- Environmental changes: Changes in your operating environment such as temperature shifts can affect the accuracy of MTBF calculations.

Variations of MTBF

- Mean Time to Failure (MTTF): While MTBF is useful for understanding repairable items, MTTF measures the reliability of assets that cannot be repaired.

- Mean Time Between System Aborts (MTBSA): This metric helps professionals assess the reliability of software systems.

- Mean Time Between Critical Failures (MTBCF): This variation of MTBF value only takes failures that quality as critical into account.

- Mean Time Between Unscheduled Removal (MTBUR): The aviation sector often uses MTBUR to calculate the flight hours between the removal of components from a fleet. This accounts for all kinds of removals, not just removal that results from component failure.

More maintenance metrics

Remember, MTBF doesn’t tell you everything. Minimizing the number of breakdowns you experience and maximizing the lifetime productivity of your assets requires close attention to a number of maintenance metrics.

- Failure rate: This metric looks at the total number of failures an asset has experienced over a given period of time or throughout its life.

- Mean Time to Repair (MTTR): How long does it take for technicians to complete repairs? This metric lets you know.

- Overall Equipment Effectiveness (OEE): Taking availability, performance, and quality into account, OEE offers a holistic snapshot of manufacturing productivity.

- Total Effective Equipment Performance (TEEP): This measure of manufacturing productivity takes all available production time into account.

- Maintenance backlog: Expressed in terms of workdays or hours, your maintenance backlog tells you how many tasks are awaiting completion. It is not realistic to aim for an empty backlog.

- Wrench time: Sometimes called tool time, this metric deals with the actual time your maintenance team spends manually performing tasks.

Want to see Limble in action? Get started for free today!

7 best practices for improving Mean Time Between Failure

Your maintenance team should always aim to maintain high-MTBF assets. Here are some tips for reducing the frequency of unexpected failures.

- Get to know your assets. Thoroughly assessing your equipment prepares you to maintain assets of all ages and can point out priority areas for improvement.

- Transition to more proactive maintenance. Develop standard operating procedures and checklists to guide your team through crucial maintenance processes like cleaning, lubrication, and replacing defective parts. By identifying potential issues before

- Introduce root cause analysis procedures. By tracing production concerns to their source, you’ll ensure your team doesn’t waste time addressing symptoms alone.

- Use high-quality replacement parts. Ensuring you only use the best, most dependable replacement parts will keep assets performing to their potential longer.

- Maintain proper working conditions. Don’t push your people or your machines past their limits and always ensure workplaces are organized and free from clutter.

- On-board and train your operators and technicians. Proper education ensures each team member understands the role they play and has the tools they need for proactive asset maintenance. Encouraging open communication between all team members promotes a free exchange of vital information and boosts productivity.

- Implement maintenance software. A Computerized Maintenance Management System (CMMS) centralizes documents, collects performance data, facilitates communication, and simplifies maintenance workflows.

The Essential Guide to CMMS

Download this helpful guide to everything a CMMS has to offer.

FAQ

Why use CMMS software to track maintenance metrics?

Using CMMS software simplifies tracking complex maintenance metrics, fosters data-driven decisions, enhancing efficiency, reducing downtime, and aiding in regulatory compliance all in one.

Is Limble Mobile CMMS app user friendly?

Limble is consistently rated Easiest-to-Use CMMS on review sites like G2, Capterra, and Software Advice. And our customers agree. With our mobile CMMS app, teams experience 30%+ better productivity, on average, requiring little to no training or ramp-up time. Our CMMS app can travel with your team, no matter where they go! Visit our App Store or Google Play for more information.

Can I connect to other systems?

Limble provides seamless, pre-built CMMS Integrations with the most widely used software systems. That means no help from a developer or your IT team is required. Learn more about our integrations.

How secure is the Limble CMMS platform?

At Limble, our world-class data security practices ensure your account information is safe. We use state-of-the-art technologies and industry best practices to maintain a secure infrastructure, including SOC-II Type II certification, regular penetration testing, and continuous security training for our staff.