Failure Analysis

Everything you ever needed to know about failure analysis.

What is failure analysis?

Failure analysis is the process of collecting and analyzing failure data, usually to identify the root cause of an asset malfunction/breakdown. This information can be used to improve machine/component design, adjust maintenance schedules, and improve maintenance processes. Ultimately, its goal is to improve asset reliability.

The failure analysis process is generally done after a failure has already occurred. It is an integral part of the RCA (Root Cause Analysis) process. However, it can also be used to determine various factors that could cause a potential failure – so we can select and apply the right prevention methods.

Depending on its purpose, failure analysis can be performed by plant and maintenance engineers, reliability engineers, or failure analysis engineers.

Maintenance engineers conduct primary failure analysis based on their knowledge of the plant operations. If the internal team doesn’t have the required expertise, it is advisable to hire consultants that provide failure analysis services.

Last but not least, reliability engineers employ different failure analysis techniques to improve fault tolerance and ensure the robustness of their system.

Common use cases for failure analysis

The most common reasons to conduct failure analysis are discussed below.

Identifying the root failure causes

In many cases, machine failures are surface-level manifestations of deeper problems that were not addressed in time. Sometimes, a combination of different factors leads to an unexpected breakdown.

Since breakdowns are so expensive and disruptive, maintenance teams need to put a lot of effort into preventing them. Aside from routine maintenance, identifying root failure causes – and eliminating them – is the best way to keep breakdowns at bay.

Preventing potential failures

A machine or system has many interconnected and interdependent components. These components do not have the same probability of causing a system-wide failure. Information and data on the system can be used to analyze the probabilities of potential failures.

Tests and simulations can be run to find the weakest links and improve them – be it through design tweaks or by changing operating and maintenance recommendations.

Improving product design

As we just alluded to in the previous paragraph, failure analysis can be done to improve equipment or component design. Engineers can employ different failure analysis techniques to identify potential issues in their designs.

On a more practical side, they can also conduct destructive testing to evaluate the characteristics of components and materials they plan to use in their final product.

The insights gained from these tests and analyses are used to create or improve product quality.

Ensuring compliance

Regulations and standards imposed by governments or industry bodies often require failure analysis. Failure analysis methods are used to ensure the product adheres to the required standards.

Liability assessment

Legal proceedings related to failures require the cause of a failure to be analyzed. The same is done as a part of specific insurance claim settlements to ensure the conditions in the contract are met. In such cases, failure analysis might be a legal requirement.

Naturally, the result of failure analysis can also be used as protection from litigation.

Common failure analysis techniques

Failure analysis is not an exact science. It is a curious exploration of the true cause behind failures and it can be considered a craft.

Still, failure analysis cannot be done without any structure. Over the years, engineers developed quite a few techniques that can be used as a framework to analyze all kinds of failures.

The most popular failure analysis techniques are discussed below.

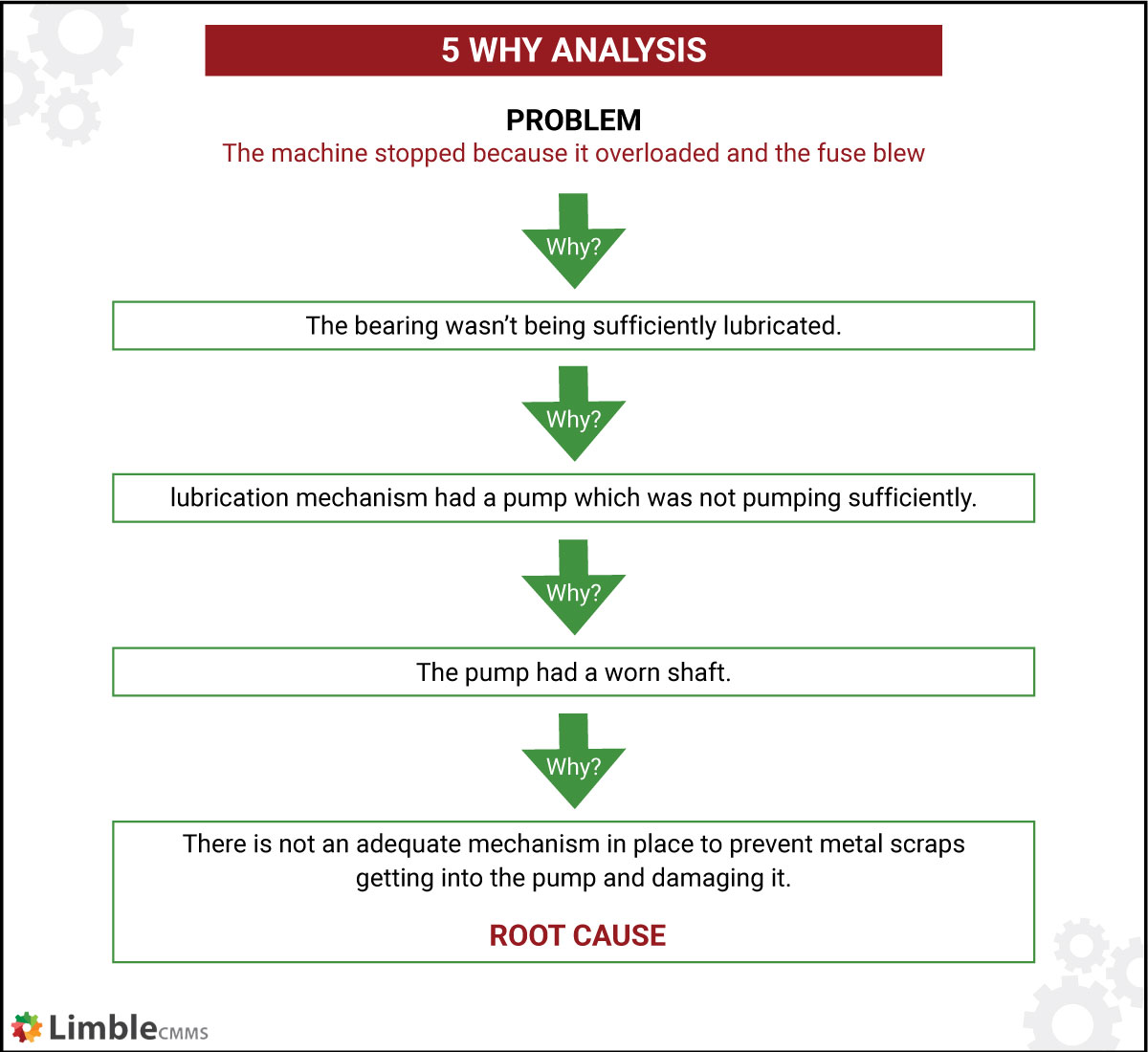

5 Whys

5 Whys represents a simple methodology used to identify cause and effect relationships between events. It is based on asking “why” the initial problem happened. The first answer then forms the basis for the next “why” question. We keep asking this until we get to something fundamental or completely outside of our control.

Recommended reading: 5 Whys: The Ultimate Root Cause Analysis Tool.

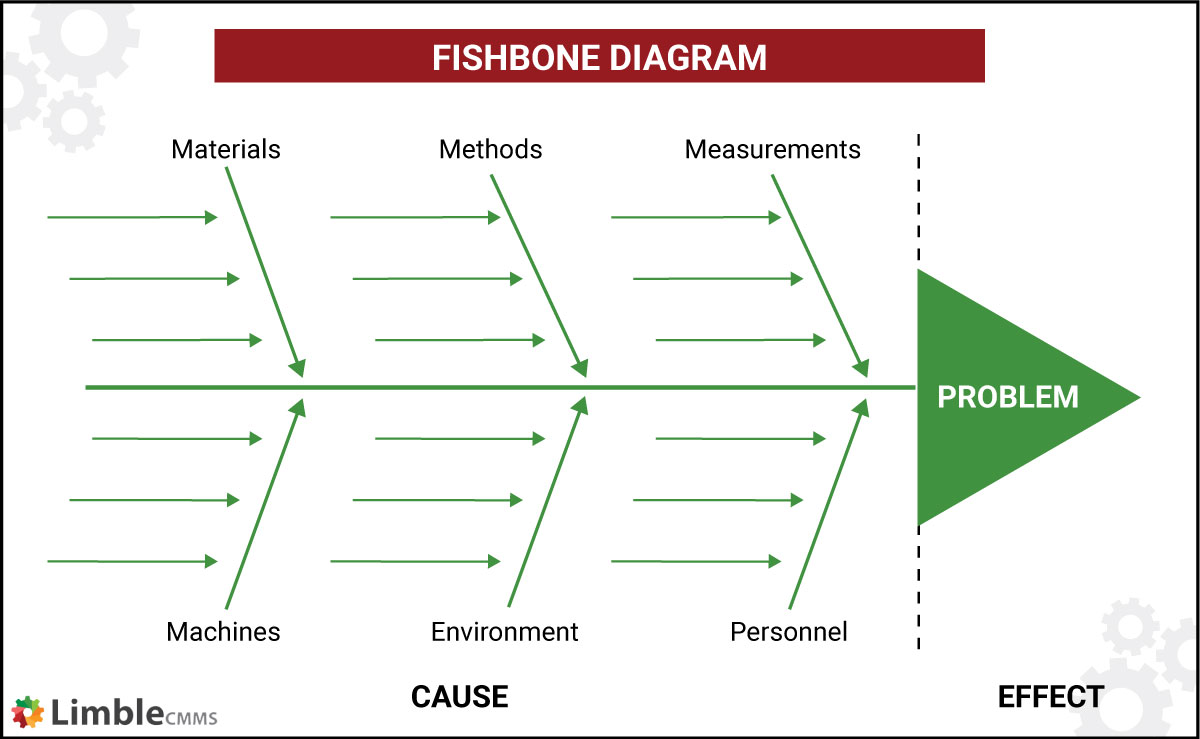

Fishbone Diagram/Ishikawa Diagram

Fishbone diagram (a.k.a. Ishikawa diagram) is a failure analysis technique that is visualized in the form of a fishbone. The head represents the problem we are analyzing while the bones represent potential causes.

The whole diagram is predicated on the idea that multiple factors can lead to the failure/event/effect we are investigating. It is widely used for process improvement in the medical field, aerospace industry, and IT.

Recommended reading: How to Use the Fishbone Tool for Root Cause Analysis.

Failure modes and effects analysis (FMEA)

FMEA is a preemptive failure analysis technique. It is used to predict potential failures with the help of past data and future projections. It takes a look at the potential ways in which a machine fails and the consequences of each such failure.

Failure modes and effects analysis is a preventive fault analysis technique where each part of a system is brought under the scrutiny of an expert team. It serves as a framework to instigate rigorous brainstorming sessions.

The technique is extensively used in reliability engineering, safety engineering, and quality control.

Recommended reading: FMEA & FMECA: How To Perform Failure Mode And Effects Analysis.

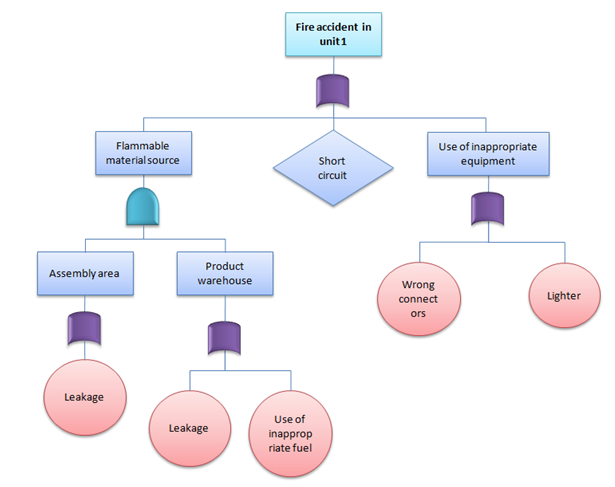

Fault Tree Analysis (FTA)

Fault tree analysis makes use of boolean logic relationships to identify the root cause of the failure. It tries to model how failure propagates through a system. This helps reliability engineers create well-defined systems with proper redundancies where component failures do not always cascade into system-wide failures.

FTA is widely used in the aeronautical industry, power generation, and defense.

Recommended reading: What Is Fault Tree Analysis And How To Perform It.

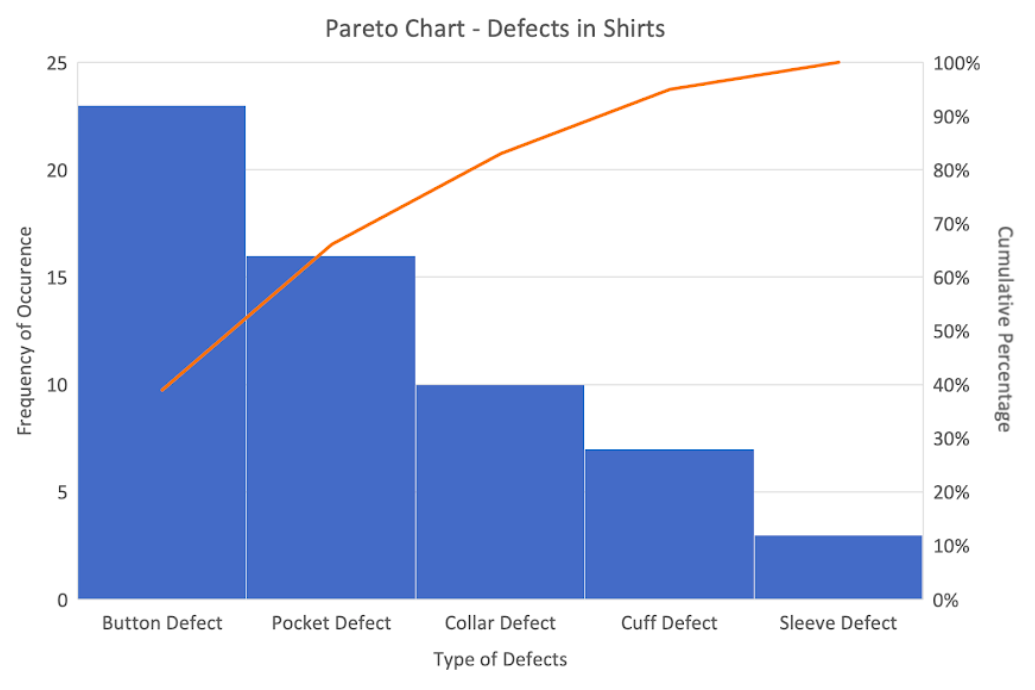

Pareto charts

A common rule-of-thumb states 80% of outcomes (or failures) result from 20% of potential reasons.

The principle is dubbed the Pareto principle (some know it as the 80-20 rule). This skew between cause and effect is evident in many different distributions, from wealth distribution among people and countries to failure causes in a machine.

Pareto charts are quantitative tools to identify the root causes that cause the most number of failures. They are widely used in scenarios where multiple root causes have to be addressed but the resources are scarce.

Recommended reading: How to Conduct Root Cause Analysis Using Pareto Charts.

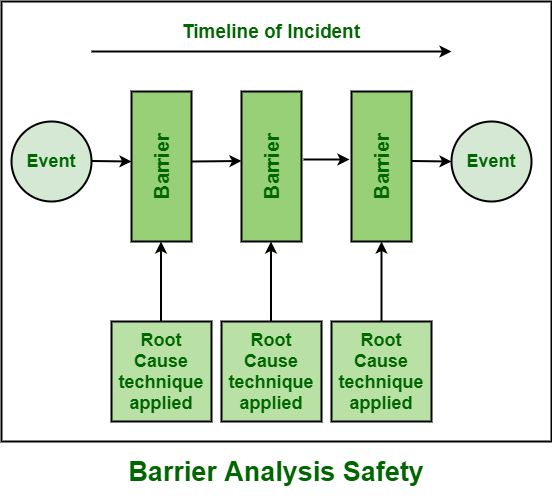

Barrier analysis

Barrier analysis is a root cause analysis methodology that determines the barriers to the safety of the target. Here the target is defined as the component or machine or system that is to be protected from failure.

The various pathways that could cause machine failure are identified. Elements in these pathways that act as barriers to safe operation are determined. They are altered to eliminate the problems in the system.

Barrier analysis identifies the impediments to successful operations. The barriers are circumvented or eliminated as a result. It is a root cause analysis technique widely used in the IT industry.

Recommended reading: Sample of a Barrier Analysis for Root Cause Investigations.

Checklist for Creating a Preventive Maintenance Plan

Following a consistent Preventive Maintenance Plan can make life easier. Use this checklist to create your own!

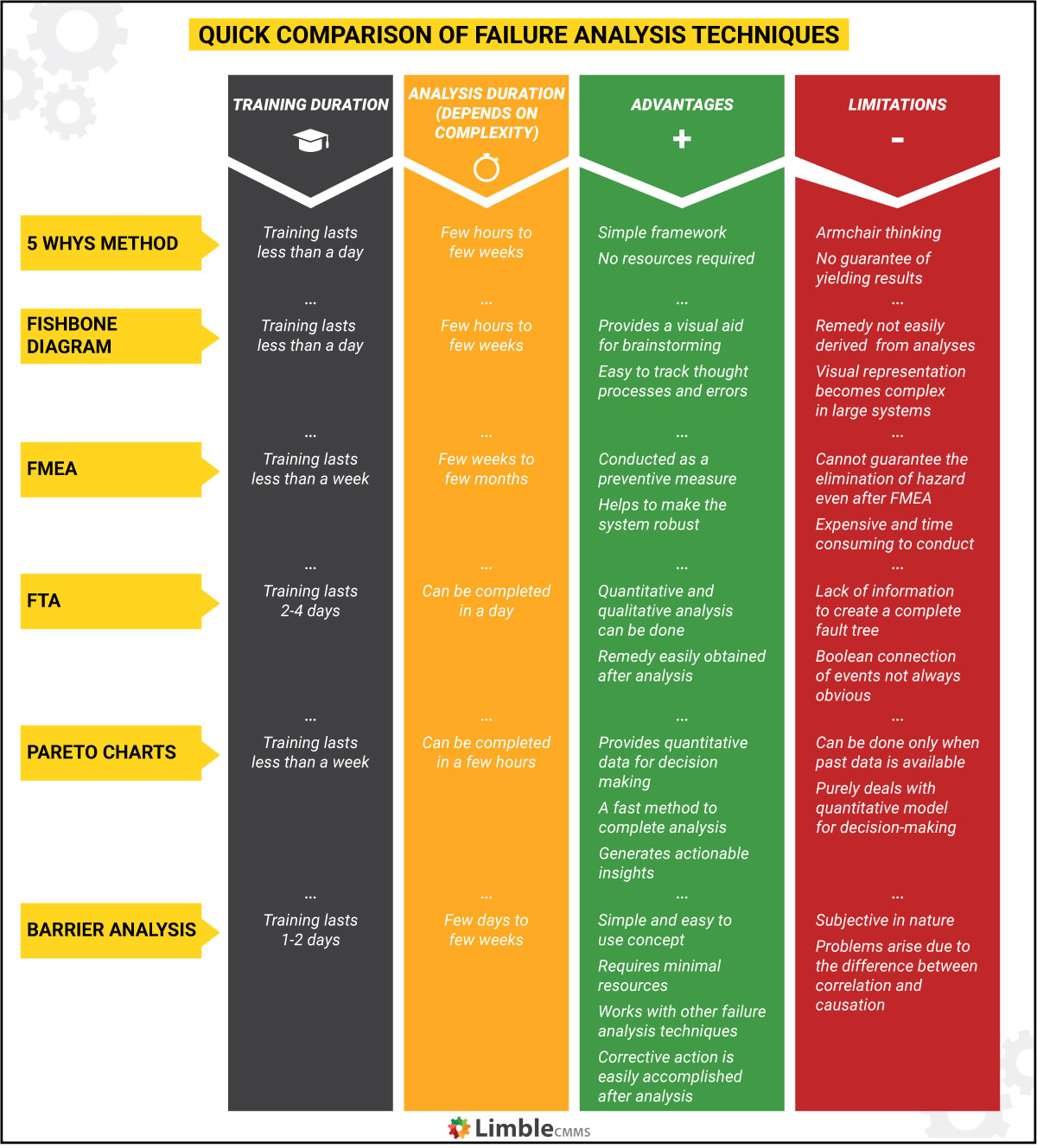

A quick comparison of failure analysis techniques

Below is a quick table that compares FA techniques based on the time needed to train your internal team to use them, how long it takes to conduct each, as well as the main advantages and limitations of the respective failure analysis methods.

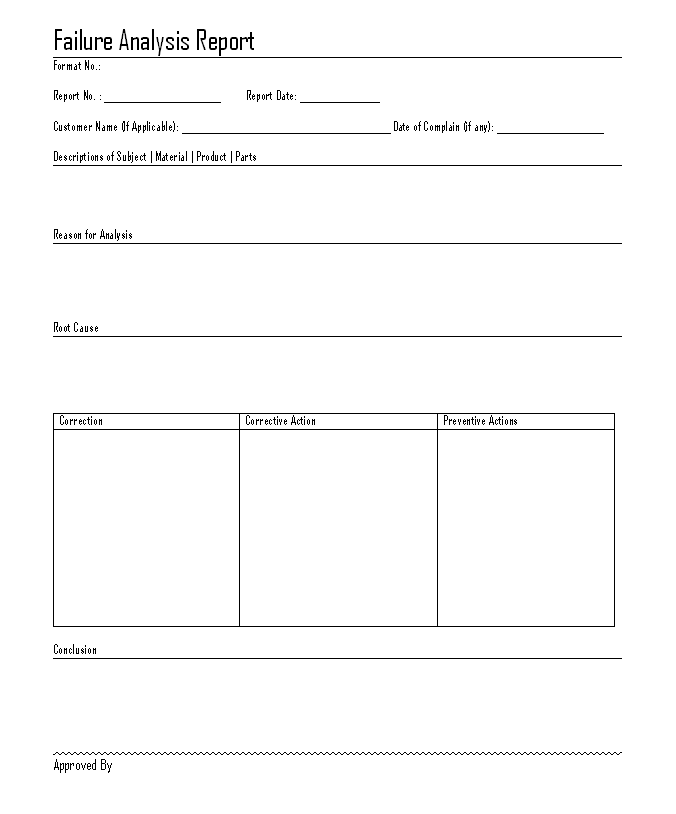

A few failure analysis report examples

A sample of a basic failure analysis report. Source: Inpaspages

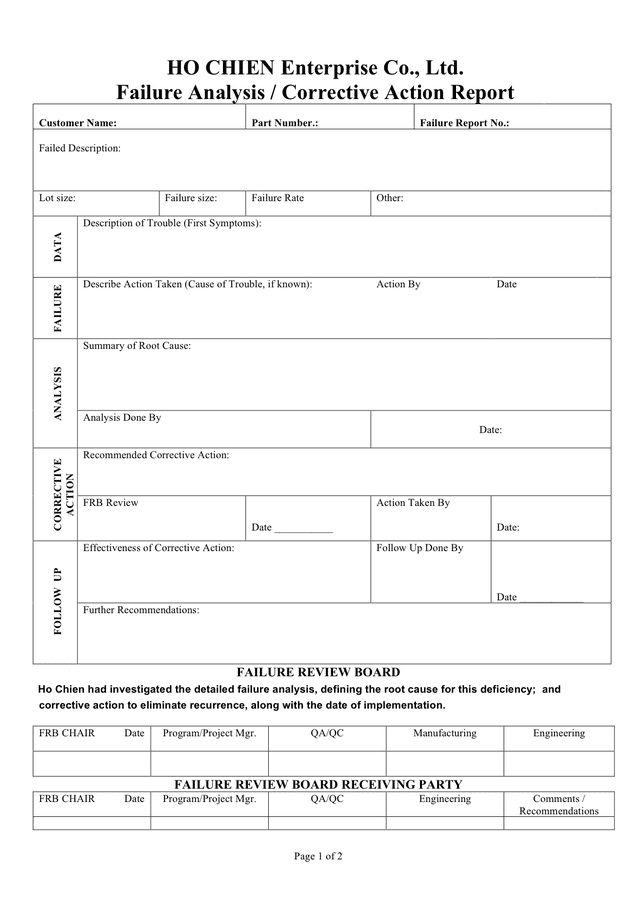

More comprehensive failure analysis report form. Source: Dexform

You can find many other examples on the web by searching for “failure analysis report” and taking a look at Google’s “Images” section.

Want to see Limble in action? Get started for free today!

Key takeaway

Failure analysis is a versatile tool that has many purposes. It can be used to investigate past failures, understand failure mechanisms, and predict the modes of future failures.

There is no “one size fits all” solution to conducting failure analysis. The technique selection will depend on the goal of the analysis, available resources, access to relevant data, and what the failure analysis team knows and prefers to use.