People often use the terms maintenance and reliability interchangeably. However, they are two separate concepts. While there is some overlap, their scope and focus are quite different.

Understanding those differences, as well as how each concept impacts the other, is a necessary step for optimizing the performance of your assets.

Defining maintenance

The ISO 14224 standard defines maintenance as a “combination of all technical and administrative actions, including supervisory actions, intended to retain an item in or restore it to a state in which it can perform a required function.”

In other words, maintenance encompasses all of the reactive and proactive actions we take to keep assets in optimal working condition.

Equipment is designed to perform a function. Maintenance ensures it functions as designed.

Defining reliability

The same standard defines reliability as the “ability of an item to perform a required function under given conditions for a given time interval.”

We’ve kept the “required function” component of the maintenance definition but introduced two new variables: time and condition. This implies that maintenance is a part of reliability, with reliability being a much broader concept that includes the asset’s operating context.

Checklist for Creating a Preventive Maintenance Plan

Following a consistent Preventive Maintenance Plan can make life easier. Use this checklist to create your own!

Maintenance as a subset of reliability

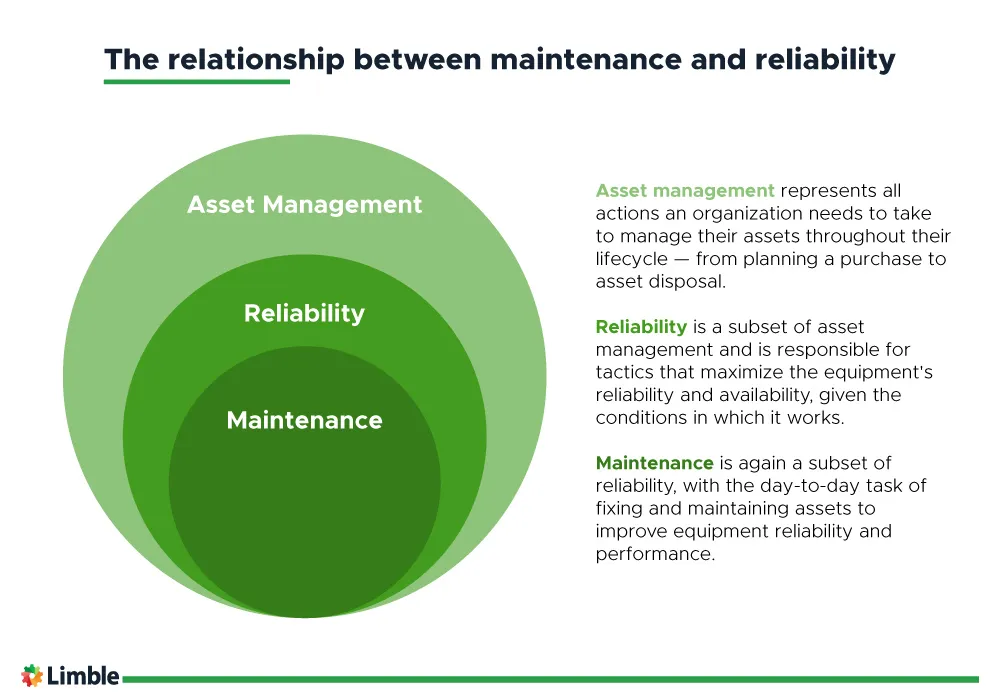

The easiest way to understand the relationship between maintenance and reliability is to look at how they fit into the concept of asset management:

- Asset management represents all actions an organization takes to manage assets throughout their lifecycle — from planning a purchase to asset disposal.

- Reliability is a subset of asset management and refers to the tactics used to maximize the equipment’s reliability and availability, given the conditions in which it works.

- Maintenance is again a subset of reliability, referring to the day-to-day tasks of fixing and maintaining assets to improve equipment reliability and performance.

In other words, both maintenance and reliability support asset management and help companies reach their business goals.

The difference between maintenance and reliability

The main goal of the maintenance actions we take — and the reliability techniques we apply — is to minimize downtime and ensure high levels of asset performance. But here is where the similarity ends.

To understand how they differ, we have to talk about the way a piece of equipment is designed.

Imagine an asset that is not performing as reliably as it was designed to. Ramping up its preventive maintenance program is likely to result in improved asset reliability and performance. However, beyond a certain point, it doesn’t matter how well you maintain an item. You will never exceed the level of reliability that has been built into the asset without changing its design.

Reliability, on the other hand, is not limited in the same way. If a piece of equipment needs to be redesigned or modified to work better within the organization’s specific operating conditions, reliability engineers can make that happen.

An example of how reliability and maintenance work together

Let’s assume an original equipment manufacturer supplies a specific pump model and capacity to a manufacturing business. However, an analysis of the pump’s performance over the past year indicates an unacceptable number of leaks caused by mechanical seal failures.

Maintenance already has a preventative maintenance regime in place to inspect the seals after a certain number of operating hours. They try to solve the problem by applying the following tactics:

- Trial the same form, fit, and function of mechanical seals manufactured by different OEMs.

- Implement condition monitoring to send an alert when seal degradation reaches a predetermined point.

- Increase the min/max levels of the mechanical seals in stock.

- Develop a quick change pump unit to ensure the pump can be removed and replaced with the least disruption to production while seal replacement occurs in the workshop.

All these measures result in mildly improved reliability and fewer breakdowns, improving availability. Unfortunately, these actions also led to higher maintenance costs and increased administrative burdens.

Reliability engineers decide to analyze the pump specifications, operation, and maintenance. They conclude that operating conditions in the factory may be the root cause of the pump’s low reliability.

They trial a different pump design fitted with labyrinth oil seals rather than the mechanical ones used in the original pump. They also recommend ways the production can be modified to minimize pump stop/start cycles.

Post-modification testing shows an improved mean time between failures due to fewer seal failures, lower maintenance costs, and improved equipment availability.

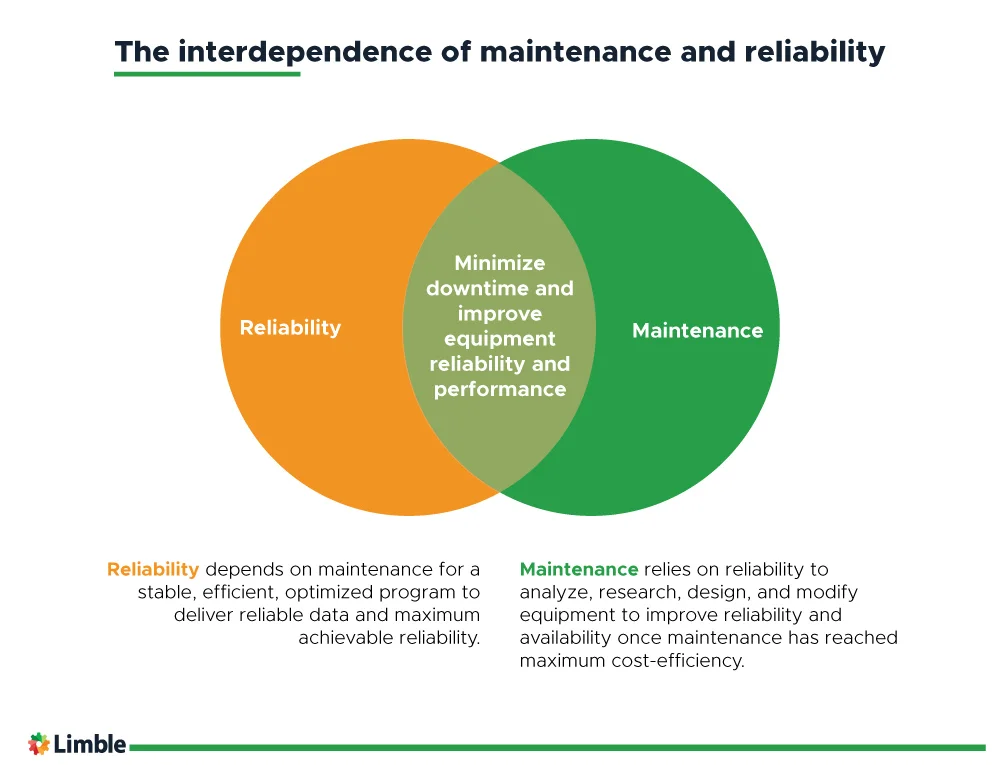

The interdependence of maintenance and reliability

The above example illustrates how interdependent maintenance and reliability really are.

Reliability depends on maintenance for a stable, efficient, and optimized program to deliver useful data and maximum achievable reliability.

Maintenance, on the other hand, is very task-focused. It needs reliability to analyze, research, design, and modify equipment to improve reliability and availability once maintenance has reached maximum cost efficiency.

Although their tasks are very different, when combined, these two disciplines produce financial results that are more than the sum of their parts.

Creating a united front

A perfect maintenance strategy, executed efficiently, still may not provide acceptable reliability.

Similarly, an organization with acceptable reliability does not necessarily mean the maintenance program is at its best or is efficiently executed.

By recognizing the relationship between maintenance and reliability, and encouraging a united approach to asset management, an organization can increase production capacity, reduce maintenance costs, lower costs of asset ownership, and ultimately boost its revenue.