An effective maintenance department is process-driven, using process mapping and flow charts to align maintenance processes with company objectives and optimize maintenance workflows for both efficiency and effectiveness.

In this post, we’ll explain what exactly maintenance workflows are, what process mapping is, show you how to apply it to your maintenance workflows, and discuss potential benefits.

What is maintenance workflow?

A maintenance workflow is essentially the sequence of steps and processes involved in completing a maintenance task, from the initial maintenance request to final completion and documentation. It’s a structured approach that ensures maintenance activities are carried out efficiently, consistently, and effectively.

An effective maintenance workflow comprises four key stages:

- Work initiation and authorization: The initiation stage where the work request is generated. On approval of the service request, the maintenance process begins.

- Maintenance event planning and deployment: Following authorization, a comprehensive maintenance plan is developed, outlining the necessary procedures and resources. Subsequently, maintenance personnel are dispatched to the asset location, equipped with the required tools and instructions.

- Task execution and equipment restoration: The maintenance work is carried out according to the established plan, with the goal of returning the equipment to its optimal operational state. This stage involves hands-on repairs, replacements, and adjustments.

- Reporting and diagnostic analysis: Upon completion of the work, reports are generated specifying the nature of equipment failure, diagnosis of the problem, and details of repair and replacement procedures.

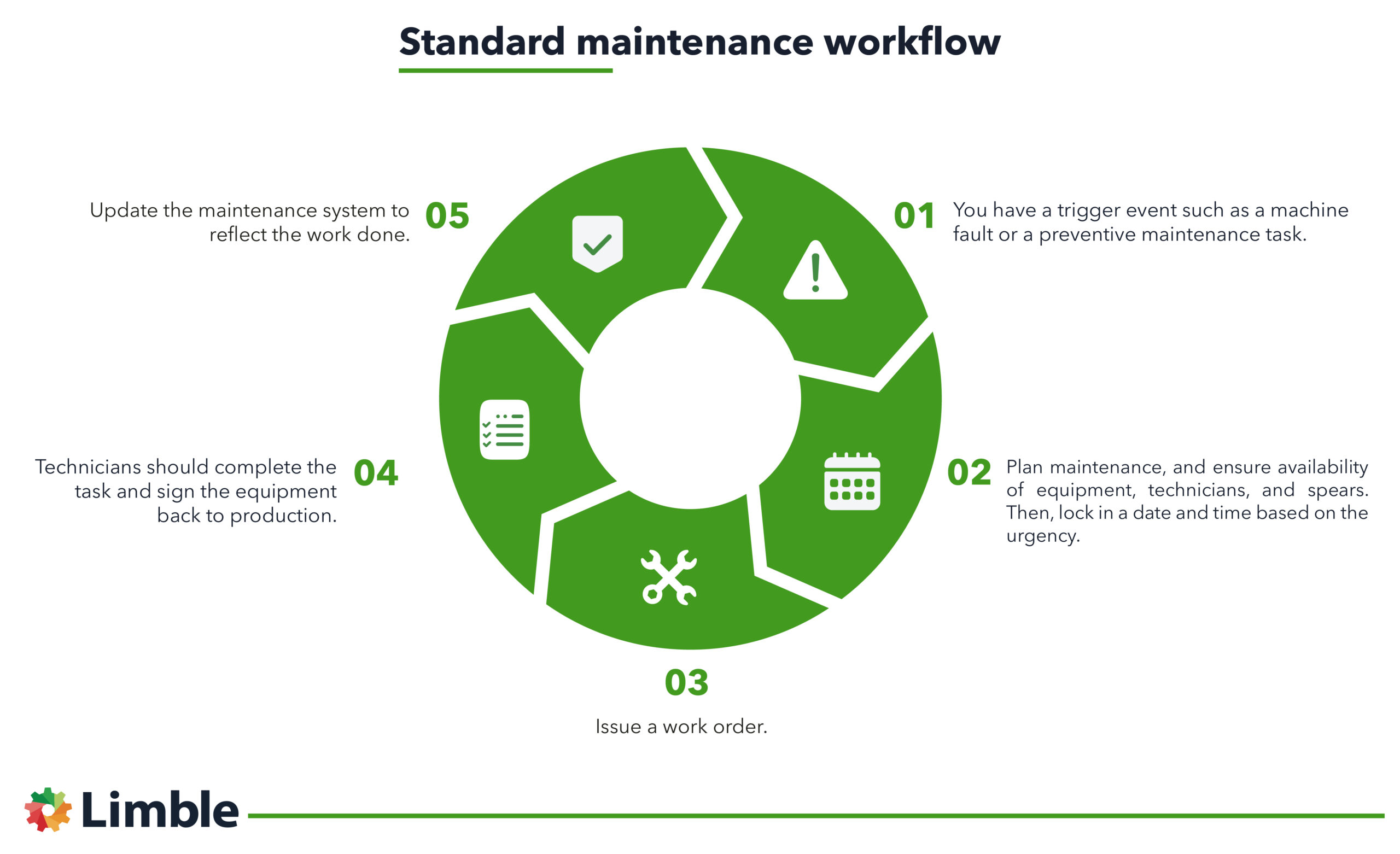

Maintenance workflow is usually initiated by a certain trigger. Here are the steps of a standard maintenance workflow.

Let’s explain the above image with a concrete example:

- A reliability engineer receives oil sampling results from a lab indicating that the oil in a conveyor drive gearbox has deteriorated and requires changing.

- The engineer raises a work request for the gearbox’s oil and filter to be changed within the next two weeks and lodges this with maintenance.

- The maintenance planner checks:

- That the oil, seals, and filters are in stock

- Determines the average hours needed for the task from maintenance history

- Looks at the production plan to find and secure suitable downtime

- Reviews the shift roster to ensure technical resources are available

- Raises a task work order

- Issues the task to the appropriate maintenance supervisor

- The maintenance supervisor assigns the task to a technician.

- The technician draws the oil and filters from inventory and books out the special tooling for the filter removal.

- The technician carries out the task, tests for leaks, and signs off the work order showing the used spares and consumables. They return the work order to their supervisor.

- The supervisor reviews the task, countersigns, and returns the work order to the maintenance planner.

- The maintenance planner updates the task in the maintenance system and resets the oil sampling frequency.

What is maintenance management?

Maintenance management is the organized process of planning, executing, and controlling maintenance activities to ensure that assets and equipment operate efficiently and reliably. It’s a critical function for any organization that relies on physical assets to conduct maintenance operations.

Here’s a breakdown of what maintenance management entails:

- Planning. This involves developing preventive maintenance schedules, determining resource allocation requirements, and creating maintenance strategies (preventive, reactive, and predictive maintenance).

- Organizing. This includes assigning tasks, managing personnel, and coordinating with other departments.

- Executing. This refers to carrying out the actual asset maintenance work, whether it’s routine inspections, repairs, or replacements.

- Controlling. This involves monitoring maintenance activities, tracking asset performance, and making adjustments as needed.

- Improving. This is the constant analysis of maintenance data, and the implementation of improvements to the preventive maintenance program.

Key aspects of maintenance management include:

- Asset management: Tracking and managing the lifecycle of critical assets.

- Preventive maintenance: Regularly scheduled maintenance to prevent breakdowns.

- Predictive maintenance: Using data and technology to predict when maintenance is needed.

- Reactive maintenance: Repairing equipment after it has failed.

- Inventory management: Managing spare parts and materials.

- Work order management: Tracking and managing maintenance tasks.

- Performance measurement: Using key performance indicators (KPIs) to assess the effectiveness of maintenance activities.

The difference between asset management vs maintenance management

While both asset management and maintenance management contribute to optimizing asset utilization, they differ significantly in scope and focus.

Maintenance management primarily concerns itself with the physical upkeep and operational efficiency of assets. Its activities include scheduling and executing maintenance tasks, managing spare parts and personnel, monitoring equipment performance, and analyzing maintenance costs. Typically, organizations use CMMS software to track these operational details.

Asset management, on the other hand, adopts a broader, lifecycle-oriented perspective. It encompasses strategic planning and financial forecasting for asset acquisition, operation, and retirement. This includes optimizing asset utilization to maximize value, conducting risk assessments, and using data analytics for informed investment decisions. EAM systems, which often incorporate CMMS functionalities, are commonly used for this comprehensive management of asset lifecycles.

Process mapping explained

Process mapping is a technique that uses flowcharts to explain the steps of a process. This technique helps team members to understand how to complete and optimize certain tasks without verbal explanations. It can be used in any business and industry, including maintenance.

Let’s check the six steps of process mapping.

Step #1 – Process identification

Start with a clear objective and scope of work for all change management tasks. This first step identifies the process to be mapped and the reasons for the exercise. Define what success will look like when complete, who the exercise will involve, and the business areas where the review will take place.

Step #2 – Gather data

This step interacts with all those using the process to understand what triggers it, the steps and people involved, interfaces between individuals and departments, and the duration of each task.

Step #3 – Map the process

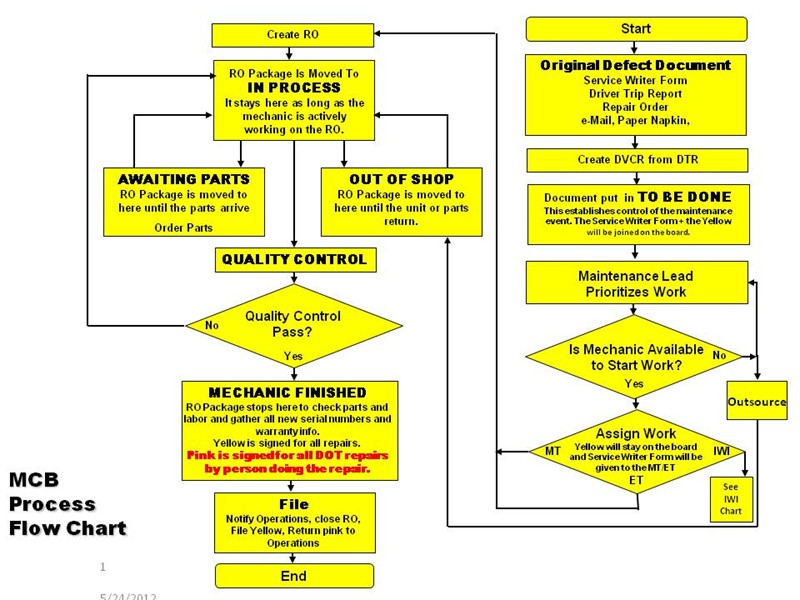

Process mapping is a graphical representation of the chain of activities that begins with a trigger and ends in an outcome. It uses symbols to show the flow direction and all inputs, outputs, delays, and steps. However, you don’t have to be a process mapping expert – as long as you can show all paths, decisions, and loops from beginning to end.

Example of a process mapping. Source: Geaslin Group

Step #4 – Analyze your findings

Start working through your map to challenge every step. Use the 5 Whys to challenge:

- What is being done?

- By whom?

- Where the task takes place?

- The time or point in the process?

- The method used to complete the task?

Step #5 – Modify and streamline

Steps three and four provide insight into unnecessary steps, parallel tasks that add no value, loop-backs that delay, and waiting times that you might avoid. Rearrange the process to remove all steps that add no value to the outcome, relocate actions for efficiency, and add new steps where required.

Step #6 – Review and manage

Implement the revised process with the support and understanding of your maintenance team. Monitor the outputs against the objectives stated in step one of the mapping process. Modify, fine-tune, and adjust, then issue the updated process for use.

Now that you’re familiar with the concept of process mapping, let’s show you how to apply it to your maintenance workflows.

The benefits of mapping your maintenance workflows

Mapping your maintenance workflow provides six important benefits.

1. Business process improvement

Processes change over time, gathering extra steps and redundant tasks, with some processes set up poorly from the start. Mapping what is being done allows comparison against what others think is actually occurring. It also allows a graphical representation to make the process less abstract, highlighting unnecessary loops and steps.

Finally, it shows interfaces where unacceptable delays may occur when the process moves from one department to another. Identifying such inefficiencies is the first step towards improvement.

2. Workflow clarification

Mapping a workflow is useful to help outsiders and those involved to understand the sequence of events, their purpose, and expected duration. In our worked example above, the reliability engineer can review the workflow to understand how to proceed.

3. Role clarity

People carrying out a process may not always be clear on the requirements of their role, the interfaces required of them, and the procedures they need to follow to acquit their part. A new maintenance planner might review the workflow to understand the six steps they must undertake upon receipt of a work request.

4. Internal audit

Auditing for process compliance or regulatory breach is easier with a clearly defined workflow against which to measure observed work.

For instance, the audit may find that seals are not being drawn from stock when a gearbox oil change is called (despite the requirements of the work pack) or that the reliability engineer requested the work by email rather than formally raising a request.

5. Regulatory compliance and accountability

Where a regulatory breach has serious financial or legal repercussions, a process removes any doubt about the steps and procedures to follow and who must complete them. If a breach occurs, like gearbox oil being poured down the drain instead of placed in the oil recycling drum, the process pinpoints who to speak to.

6. Training improvements

A process identifies areas where an individual maintenance technician or team fails to meet expectations, and whether remedial maintenance training is required. If our maintenance planner constantly receives completed work orders that the supervisor hasn’t signed, the maintenance manager can address the issue using the process workflow as an example.

How to use CMMS system to optimize your maintenance workflow processes

A Computerized Maintenance Management System (CMMS) provides immediate benefits for workflow optimization:

- It enforces process discipline by becoming the sole method of logging issues for maintenance rectification and avoiding informal procedures. The work order will not be raised if it’s not correctly logged in the CMMS.

- When logged, the prioritization of work requests enables the CMMS to schedule tasks for planned maintenance periods that are appropriate to the urgency. It also can raise notifications and alerts to senior staff for high-criticality items.

- By centralizing all data in one database, the CMMS ensures an audit trail from task initiation to completion, highlighting personnel actions, spares used, and contractors engaged.

- The maintenance program is automatically updated, with completed tasks and work-arising captured and the next-due dates and times advanced.

- The CMMS assists with resource allocation and scheduling by indicating the number and specialty of all personnel required for planned maintenance shuts, tooling and spares required, and the time needed to complete the work. The in-service database within the CMMS allows data mining and analysis to identify efficiency metrics for continuous improvement initiatives.

- The CMMS allows you to quickly create, store, and access standard operating procedures, maintenance checklists, and safety guidelines which are key documents for standardizing maintenance work.

- A CMMS can provide dashboards to visualize asset performance in real-time, along with other key metrics, aiding in data-driven decision-making.

- Maintenance tasks automation, such as work order generation, task assignment notifications, and reporting, contributes to efficiency and cost savings.

Other useful methods for maintenance workflow optimization

There are numerous practical steps that a maintenance organization can take for process optimization.

Kitting

A tactic used in the preparation of a maintenance task. It comprises the assembly of a kit of the spares, tools, and consumables required to acquit the work.

Store personnel carry-out kits ahead of the maintenance date once the task is entered, identifying the kit against the work order number and quarantining the kit to ensure it is available when the technician requests it. Kitting makes the technician more efficient on maintenance day while ensuring all resources are available.

Move asset care tasks to operators

Moving asset care tasks to operators provides three benefits to a business. It helps remove any us-versus-them issues between maintenance and production, ensures important and frequent tasks like cleaning and lubrication are done rather than ignored by maintenance staff, and assists in maintaining equipment reliability and design lifespan achievement.

Identify and group tasks

Identify and group tasks or procedures being carried out at different times or by multiple people in different areas. Grouping increases efficiency and streamlines processes.

Provide portable digital devices

Provide portable devices to place the maintenance documentation where the maintenance tasks are underway. Digitalization of documents maintains version control and eliminates paper copies from compromising quality management systems; it also prevents travel time by technicians to access centrally located computers or paper manuals.

Start making improvements today

Efficient maintenance systems comprise multiple processes that need to be aligned and streamlined. By mapping each process and removing redundancies, overlaps, and unnecessary steps, you will optimize your maintenance workflow, make your employees more effective, reduce confusion, and save your business a lot of time and money.

Schedule a demo or start a free trial to see how Limble CMMS can help you with the optimization of your maintenance workflows.