Fixed Asset Management

Everything you ever needed to know about fixed asset management.

What are fixed assets?

Fixed assets generally have a long asset lifecycle. Investopedia offers a great definition:

“A fixed asset is a long-term tangible piece of property or equipment that a firm owns and uses in its operations to generate income. Fixed assets are not expected to be consumed or converted into cash within a year. Fixed assets most commonly appear on the balance sheet as property, plant, and equipment (PP&E). They are also referred to as capital assets.”

In a car factory, various assets are used to assemble the vehicle. The raw materials include different metals and various other components. They have a limited life in manufacturing facilities as they are consumed fairly quickly. Because of that, raw materials are classified as part of the current assets, not fixed assets.

On the other hand, robotic arms used for assembling cars, the land on which the factory is built, and the plant structure built on top of it all have a long expected lifetime. So we can classify them as fixed assets.

The Essential Guide to CMMS

Download this helpful guide to everything a CMMS has to offer.

What is fixed asset management?

Fixed assets are procured with a large capital outlay. Increasing the useful life of such assets is part of prudent financial planning. Fixed asset management (often abbreviated as FAM) is the discipline that tracks, manages, monitors, and maintains fixed assets.

Earlier, fixed asset management had to rely on physical record-keeping and paper trails. This was cumbersome, time-consuming, and prone to errors. Today, various software tools are used to streamline asset tracking and maintenance work.

The key objectives of fixed asset management are:

- Keeping track of fixed assets. Used in financial accounting to keep asset records and the balance sheet up-to-date. This is very important for budgeting, forecasting, and asset depreciation calculations.

- Theft detection and prevention. Fixed assets are expensive so theft is often a viable concern. It is one of the reasons why fixed asset management solutions offer specific asset tracking features to monitor asset location.

- Maintaining optimal working conditions through proactive maintenance schedules. A major part of fixed asset management is keeping the assets in good operational condition. Routine maintenance is necessary to avoid unexpected failures which shorten asset lifespan and induce operational issues.

- Increasing machine uptime. Avoiding machine failures with proactive actions reduces machine downtime and improves machine availability and reliability.

- Improving asset utilization ratios. Regular monitoring of assets alerts the management of machine underutilization and performance issues. This way, early remedial actions can be taken to increase OEE and asset utilization rates.

- Extending asset lifespan. Constant monitoring and maintenance help to keep the assets in good shape. Avoiding machine breakdowns, and other catastrophic incidents will increase the lifespan of fixed assets.

Taking good care of expensive assets leads to lower asset turnover and less frequent need for capital expenditures. It’s hard to say no to that.

Common FAM challenges

Fixed asset management has to overcome certain obstacles to be effective. Common challenges on the plant flor include:

- Manual errors (like data entry mistakes) can make it difficult to monitor and track asset information accurately.

- The information flow has to go through several departments. This can significantly slow down decision-making.

- Cybersecurity threats pose a risk for any digital system. Critical infrastructure has recently come under regular cybersecurity attacks. It is vital to follow the best data safety procedures and use reliable software providers.

- Collecting data and generating actionable reports can be a challenge if the organization is managing assets using multiple apps or relying on spreadsheets and paper records.

- Managing inventory for a large number of assets is everything but simple. Though it is not a core part of fixed asset management, tracking inventory is often ancillary to tracking fixed assets.

- Tracking a huge number of assets in a large organization generates large volumes of data. Storing, managing, and analyzing ‘big data’ requires proper data management.

Here is some good news. All of these potential problems can be prevented by implementing the right software and by following best practices.

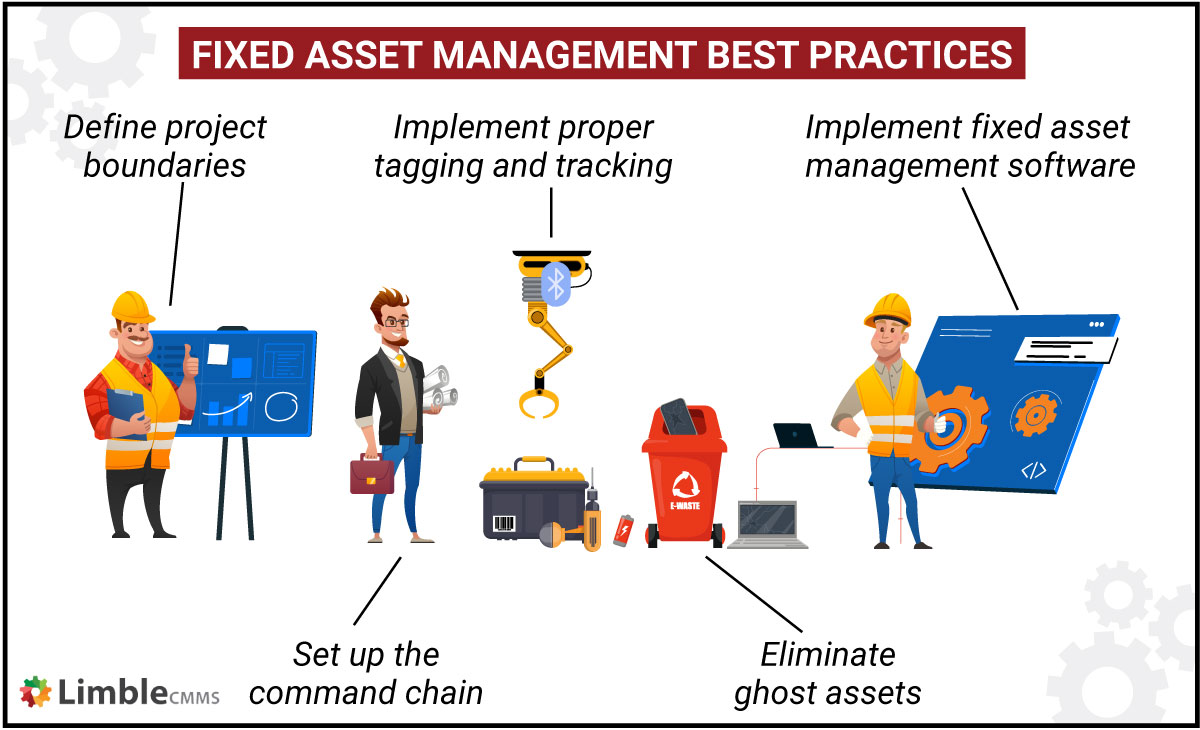

Fixed asset management best practices

To get the most value out of fixed assets, you have to follow the industry’s best practices. They will help achieve key objectives with less resistance.

1) Define project boundaries

An industrial enterprise can have a huge number of fixed assets. Each of them can be tracked and monitored through several different parameters. Keeping account of every data point can become counterproductive due to the large volume of generated data.

To avoid it, the scope of the fixed asset management project has to be laid out before the planning phase. Unbounded plans will turn out to be never-ending projects with huge cost overruns, accomplishing very little.

2) Set up the command chain

Even with the use of software, someone has to be at the helm. The responsibility of tracking and monitoring has to be assigned with well-defined, measurable metrics.

The operations/asset manager responsible for fixed asset management selects the assets that should be tracked. Naturally, based on the organizational structure, there will be other personnel to support and execute asset maintenance plans and programs.

The division of responsibilities among the different team members and departments has to be established with a well-defined chain of command.

3) Implement proper tagging and tracking

Tracking assets is one of the main functions of fixed asset management. Each organization will have specific challenges that need to be addressed.

Consider a business operation where fixed assets have to be frequently transported to remote locations. Such locations may not have network coverage to send tracking information. Fleet managers will often resort to GPS tracking equipment to maintain asset visibility in remote areas.

Aside from GPS, location tracking and asset identification can be done via Bluetooth, RFID, and asset tags (barcodes; QR code tracking).

Implementation, without a proper tracking methodology, is a waste of effort, time, and capital.

4) Eliminate ghost assets

Assets that have become unusable or don’t even physically exist, but are still listed in your fixed asset register, are referred to as ghost assets.

Keeping ghost assets on books has negative financial implications. Property taxes, insurance premiums, etc., will have to be paid if they are still tracked in the books. They distort the enterprise value in the financial statements.

Businesses should occasionally perform physical audits of their assets to find and eliminate ghost assets.

5) Implement fixed asset management software

Digital tools make fixed asset management so much easier. However, purchasing capable software is also a long-term investment. It cannot be abandoned on a whim. The selection of the software has to be done based on careful analysis of the organization’s needs and budget.

Key considerations that play a role in picking the software selection process:

- The cost of the software (and hardware it connects to) should fit within the operational budget and offer a suitable payment model (which can range from one-time payments to monthly/yearly subscriptions).

- Software vendors that offer strong technical and customer support are always a safer choice.

- The functionality of the selected solution should match your specific requirements.

- Go with a vendor which guarantees regular updates and security patches.

- Ask about implementation options. Most vendors offer cloud-based solutions, but some are also open to on-premise installations.

A fixed asset management system can help automate significant parts of your fixed asset management workflows. Automation reduces the number of personnel required to manage physical assets and lowers the associated overheads.

6) Additional tips and practices

In addition to the practices mentioned in the previous section, there are other advantageous FAM practices to consider:

- Take full advantage of financial depreciation to reduce taxes and insurance premiums.

- Comply with all the necessary regulations including data security regulations.

- Avoid the use of spreadsheets to tag and track. It is an error-ridden exercise that does more harm than good.

- The purchase and procurement of new fixed assets should be taken after considering the most advantageous timing from a financial perspective.

Getting all of these things right will be immensely helpful for overall enterprise asset management (EAM) and asset inventory management.

Use CMMS as your fixed asset management software

Modern CMMS solutions can cover all of your fixed asset management needs. They allow you to:

- easily create and update your asset registry

- connect to GPS trackers, and use Bluetooth and barcodes to facilitate multiple asset tracking options

- connect to condition monitoring equipment to track equipment condition and performance in real-time

- schedule and coordinate all maintenance and repair work and resources (tools, parts, labor) to keep assets in optimal working condition

- track a vast amount of asset data to generate actionable reports and control asset-related costs

As a cherry on top, CMMS solutions like Limble can also be integrated with popular ERP and SAP solutions. It might be an important requirement for enterprises that want to ensure unobstructed data flow across all departments.

Want to see Limble in action? Get started for free today!

Fixed asset management on auto-pilot

Fixed assets have a long life expectancy and often require big capital expenditure. Efficient management of the assets is required to eke out the maximum output from your fixed assets.

Today, fixed asset management is made easier with the help of scalable software solutions.

Still, organizations should implement and follow fixed asset management best practices. It is the only way to ensure smooth business operations, minimize operational costs, reduce equipment downtime, and improve overall business productivity.