Good reliability engineers are always in high demand. They help organizations reduce downtime and decrease maintenance costs.

If you’re planning to hire a reliability engineer — or considering a career as a reliability engineer — this article is for you. We discuss the responsibilities, required skills, and the salary that come with the job.

What is a reliability engineer?

Reliability engineers are professionals responsible for ensuring that a business’s equipment and processes operate at optimal levels and meet the needs of the organization. Their main goal is to increase equipment uptime, reliability, and efficiency.

They achieve this by analyzing data, identifying problems, and developing solutions for potential equipment issues before they occur.

Maintenance Acronym Guide

Confused by PMs, MTTR, and DFMEA? This maintenance acronym guide will have you talking the talk in no time.

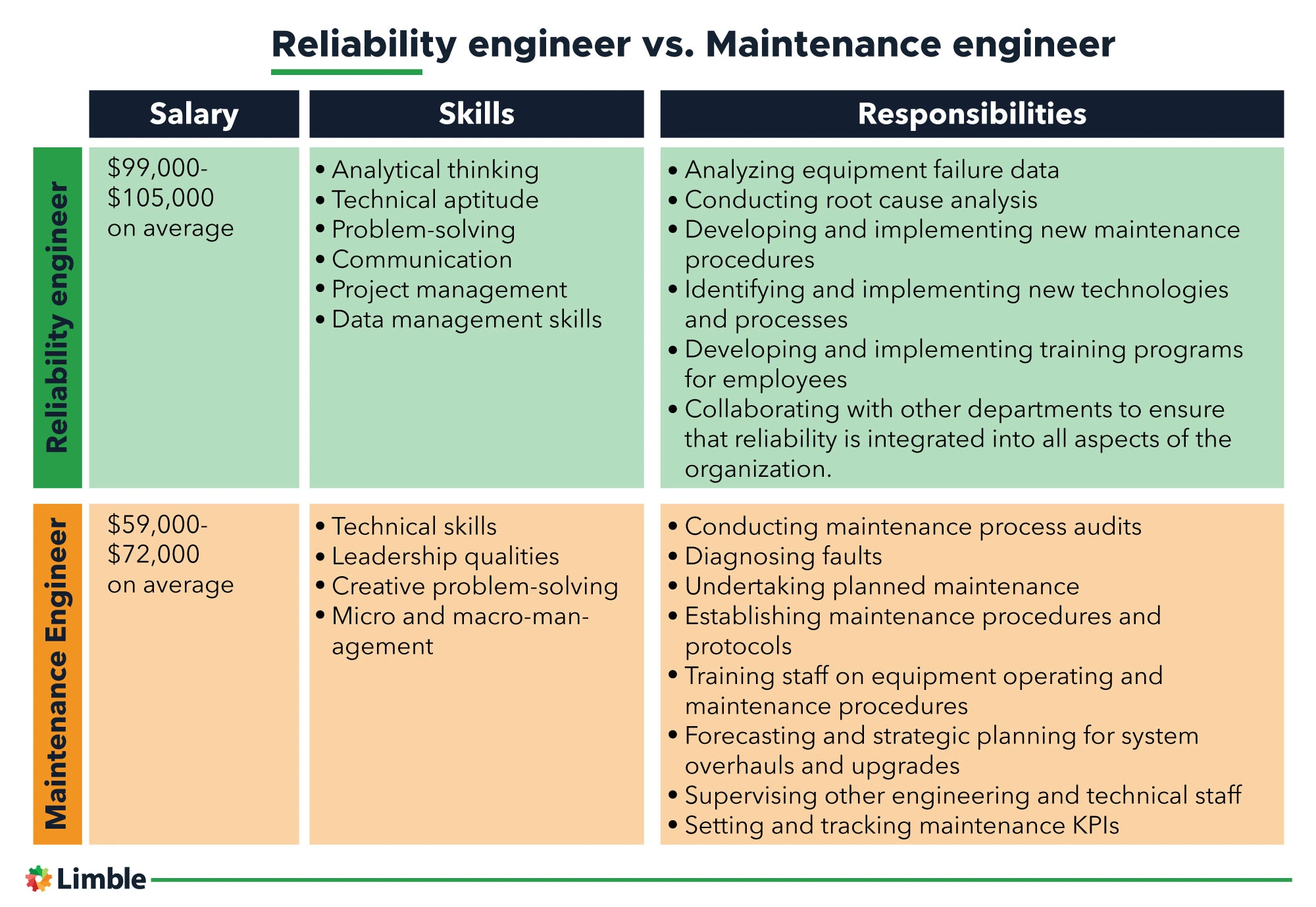

Reliability engineers vs. maintenance engineers

It is true that reliability engineers and maintenance engineers both work toward similar goals — ensuring that systems, equipment, and processes function at peak efficiency.

However, although these two professions are similar, there are some key differences related to the methods of their work.

Reliability engineers focus primarily on identifying and solving problems related to the reliability of systems and equipment. Their work entails:

- Analyzing equipment failure data

- Conducting root cause analysis

- Developing and implementing new procedures and processes

The goal of a reliability engineer is to increase the overall uptime and availability of systems and equipment, and to reduce the number of failures and downtime.

On the other hand, maintenance engineers primarily focus on the day-to-day maintenance and upkeep of systems and equipment. They:

- Schedule maintenance

- Troubleshoot equipment issues

- Repair equipment

A maintenance engineer’s goal is to ensure that systems and equipment are operating safely and efficiently by doing their part to prevent breakdowns and failures.

Reliability engineers often work together with maintenance engineers to identify and solve problems. For example, a reliability engineer may analyze data and identify a potential problem, and then work with a maintenance engineer to develop and implement a solution.

Additionally, maintenance engineers often contribute to reliability through routine maintenance which helps prevent breakdowns and failures.

Responsibilities of a reliability engineer

A reliability engineer is responsible for finding potential problems or opportunities for improvement by analyzing data and identifying patterns within that data.

Once problems have been identified, the reliability engineer will develop and implement solutions to prevent them, ultimately improving the reliability of systems, equipment, and processes.

These solutions will vary depending on the organization and the process in question.

However, some common scenarios include:

- Analyzing equipment failure data to identify patterns and trends.

- Conducting root cause analysis to determine the underlying cause of problems.

- Developing and implementing new maintenance procedures.

- Designing and implementing new procedures for monitoring and testing equipment.

- Finding new technologies and processes that can improve equipment performance and reliability.

- Developing and implementing training programs for employees.

- Collaborating with other departments to ensure that reliability is integrated into all aspects of the organization.

Skill requirements for a reliability engineer

There are several key skills that are instrumental for being a good reliability engineer:

- Analytical thinking: the ability to think critically and logically, as well as the ability to work with large sets of data and make sense of them.

- Technical aptitude: a strong understanding of the systems, equipment, and processes at hand. This includes knowledge of the engineering principles and specific systems used at an organization.

- Problem-solving: the ability to think creatively and come up with innovative solutions to complex problems.

- Communication: the ability to explain technical concepts in a clear and understandable manner, as well as the ability to collaborate effectively with others.

- Project management: the ability to manage multiple projects and tasks simultaneously and effectively including planning, scheduling, and organizing.

- Data management skills: the ability to use statistical analysis tools as well as the ability to interpret and communicate the results of the analysis.

- A continuous improvement mindset: identifying and implementing ways to continuously improve reliability.

- Safety-conscious: the ability to identify potential hazards and take the necessary steps to mitigate them.

The more of these skills a reliability engineer has, the more successful they will be in their role.

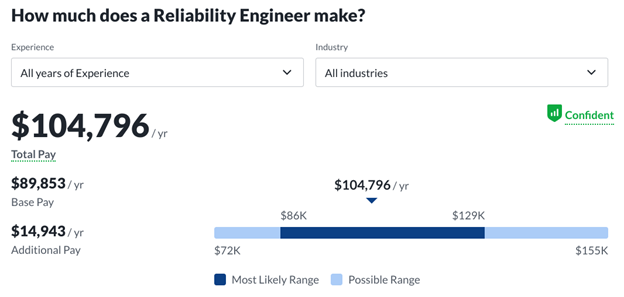

Reliability engineer salary

The salary of a reliability engineer will vary depending on factors such as the location and size of the organization, and the specific responsibilities of the role.

Here is the data we picked up from large job sites:

- Glassdoor states the range between $72,000 and $155,000 with the average salary as $105,000 per year.

- At the site Salary.com, the range of pay is listed as $65,000 to $88,000 per year.

- Indeed puts the salary range between $72,000 and $136,000, with an average of $99,000 per year.

- According to TotalJobs, the average salary in the UK is £47,500.

Recent trends show an increasing demand for skilled workers, with not enough workers to fill the jobs. This, along with the growth of the reliability engineer role, could mean that the average salary will only increase.

Final notes

The reliability engineer is a critical, dynamic position that has great responsibility and requires constant collaboration with other professionals, especially maintenance engineers.

With a reliability engineer in place, the dreaded phrase of “unplanned downtime” will hopefully be less common at your company.

To find out more about other maintenance roles and how to best organize your maintenance department check the Limble blog or the extensive list below.