Limble’s recent survey of manufacturing and facility management maintenance professionals found that preventive maintenance programs are the most popular strategy for addressing challenges like breakdowns and skill shortages. While increasingly popular, more advanced strategies like predictive maintenance and condition based maintenance are far less common.

Computerized maintenance management systems (CMMS) play an essential role in all types of maintenance departments. With tools for automating key processes, simplifying work order management, and evolving data analysis, CMMS platforms enable the transition from reactive to proactive maintenance operations.

If you don’t already have a CMMS, how can you make the case that introducing one would save time and money?

Calculating the potential return on investment of a CMMS platform is simple and tends to speak volumes. It could be the first step in making your maintenance team a valued strategic ally for the organization as a whole.

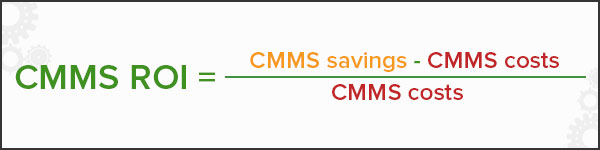

CMMS ROI formula

CMMS value reveals itself in both hard and soft cost savings.

You can calculate potential CMMS savings by adding up factors like productivity gains, downtime savings, and spare parts inventory savings.

- $351 million in downtime cost reduction

- $55 million saved on parts thanks to improved inventory management

- $798 in labor savings thanks to more efficient maintenance activities

You can calculate total CMMS costs by adding together factors like subscription costs, onboarding costs, and the costs of implementing new hardware.

Check out our free CMMS ROI calculator here.

How to calculate the ROI of CMMS software

Here’s how you calculate ROI for new CMMS software.

Imagine you’ve collected all the necessary data and made your initial calculations.

You’ve determined that the costs of implementing and using CMMS software for a year are $41,000. You’ve also determined that you’ll generate $360,000 in savings during the year.

CMMS ROI = ($360,000 – $41,000) / $41,000 = 7.78

In this case, the return on your investment after a single year would be almost 8 times what you spent.

The ROI of maintenance software is just one important metric for calculating the department’s impact. Check out our guide to essential metrics and KPIs for more details on measuring what matters to make maintenance a value driver.

How much can you save with a CMMS?

The customer success stories cited above should give you some sense of how a CMMS can improve asset management to drive down maintenance costs. Let’s take a closer look.

1) Calculating productivity gains

CMMS solutions can eliminate inefficiencies. They make it easier to follow clear workflows, access information about assets throughout their lifecycle, and communicate across teams.

To calculate productivity gains, you’ll need to answer a few questions:

- How much do you spend on each employee per hour?

- How many people will use your CMMS?

- How many hours can your CMMS software save your team during a given period?

- How many working days per year?

Here’s an example:

- Hourly cost per employee (USD/hour) = $40 ($30 wage + $10 benefits)

- Number of people using software = 8

- Number of hours CMMS saves per user each day = 2 hours

- Working days in one quarter (3 months) = 66

$40 x 8 x 2 x 66 = $42,240 (or 1056 working hours saved)

2) Savings as a result of decreased downtime

A CMMS tool makes it simple to plan, schedule, and track all maintenance tasks. This improves communication flow and helps you stay on top of your inventory. These are the pillars of a maintenance program that minimizes downtime.

To calculate downtime savings, start with these questions:

- How much does downtime cost you each hour?

- How much downtime do you experience every month?

- How much downtime can you eliminate with a CMMS?

Focus on high-priority assets. Their breakdowns will cost you the most.

Learn how Tara Manufacturing realized more than $100 thousand in downtime cost reduction.

3) Spare parts inventory cost savings

Ask these questions to begin calculating spare parts inventory management savings:

- How much do you spend on your spare parts inventory each month?

- How much savings can you expect with a CMMS?

Keeping spare parts on hand isn’t cheap. You need to manage storage space and maintain certain conditions. Limble customers reduce their inventory spend by an average of 17% thanks to our parts inventory management features.

More benefits of implementing a CMMS

Two indirect cost benefits of a modern CMMS include:

- Extended asset life

- Decreased labor costs

Reducing breakdowns is known to increase asset lifespan. Unsurprisingly, the fewer breakdowns you experience, the lower your overall labor costs. This could be because of lower overtime costs as well as reduced spending on pricey independent contractors.

It is important to keep these factors in mind while making your CMMS ROI calculations.

The costs of CMMS software

Our breakdown of CMMS costs offers a quick summary of the expenses to expect.

1) Costs of implementation

The costs of CMMS implementation aren’t all included on the price tag. You also need to consider how much time your team spends diverting their attention from other work. How much time will they spend collecting data or integrating your new platform with tools like your ERP?

Implementation cost = implementation time x hourly wage of team members(s) working on implementation

Check out our article on general CMMS implementation timelines.

2) Cost of the software itself

Many CMMS providers base their pricing plans on the number of users. Yearly subscriptions are typically more cost effective than monthly options.

Make sure you check for any hidden expenses that could creep up on you and contribute to your total costs. These could include:

- Paid add-ons

- Consulting fees

- On-going support fees

Ask your potential CMMS vendors plenty of questions to avoid any surprises.

3) Onboarding costs

This is also something you should make sure to discuss with your new CMMS provider. They may offer some estimates on the typical timeline and costs associated with onboarding new maintenance teams.

The onboarding process may consist of activities like:

- Watching video tutorials

- Watching live webinars

- Participating in a multi-stage training program

You can estimate your onboarding costs, follow this formula:

Time x Number of users x Average hourly wage = Total Onboarding Cost

4) Hardware costs

You may need to invest in additional hardware to ensure your team can make the most of its new CMMS.

Hardware costs may include:

- Mobile devices

- Wireless networks

Mobile devices are especially important for ensuring technicians can leverage mobile CMMS apps while on the move.

Calculate the potential ROI of Limble’s CMMS platform

To speed things up, we created an interactive online calculator. Before you start throwing in your numbers, here are a few things you should keep in mind:

- Some fields are automatically populated with numbers that reflect the average savings Limble users have reported

- These numbers are only meant as an estimate.

- When you’re finished entering the numbers, just enter your email address. We will send you a detailed breakdown and a link with access to additional features.

- All calculations are based on a one-year timespan. They show you what your return on investment could be one year after implementing Limble’s CMMS solution.

CMMS Buyer's Guide

Learn the questions to ask and the features to look for during the CMMS selection process - and find the right CMMS for you.