Production, machines, and maintenance are mutually interdependent. Changes in one area will always affect the remaining two. Machine monitoring is here to ensure that you always make the right changes, at the most opportune time.

In the coming paragraphs, we outline how machine monitoring works, why it is becoming increasingly popular with manufacturers, and steps to implement a machine monitoring system.

A brief history of machine monitoring

The modern manufacturing shop floor has a variety of machining equipment for various processes. This diversity has made it highly challenging for shop managers to monitor and maintain their machines.

From the start of the industrial revolution up until the last few decades, the monitoring of machines was done through a manual collection of machine data. The collected data was often filled with bias as it was driven by human experience and knowledge.

Since the machines were relatively simple, with no sophisticated controls, the information was still satisfactory. We were able to use it to produce simple decisions on how to sustain the status quo of their operation and maintenance.

With increasing market forces, the need to establish production efficiency, and new technologies emerging in the field of machine controls, the need to incorporate advanced machine monitoring systems has gained significant traction in the manufacturing industry.

Our 2021 maintenance survey shows that around 50% of manufacturers have some experience with condition-based maintenance. So, in one way or another, the majority of manufacturers have already been in touch with some type of machine monitoring systems.

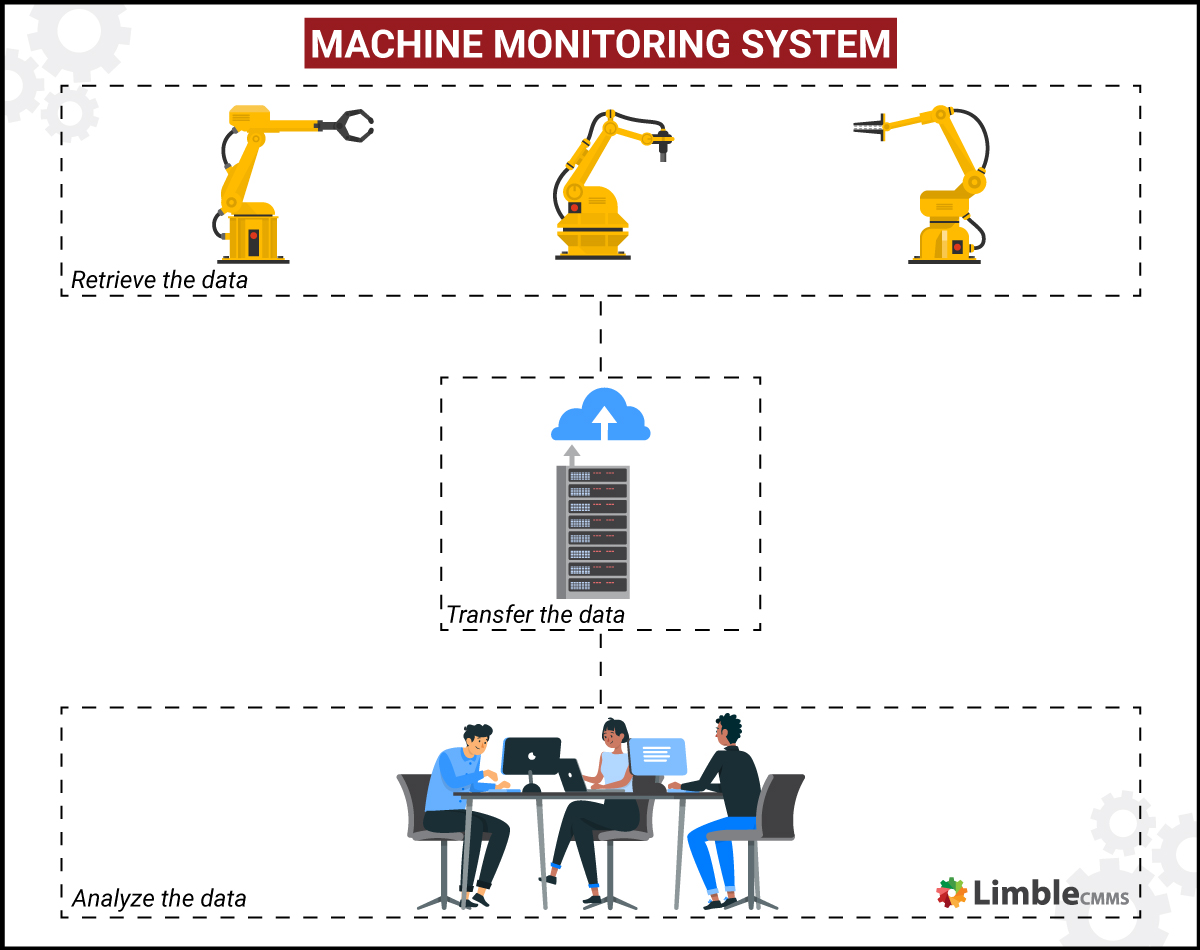

How does machine monitoring work?

Put simply, machine monitoring is a systematic process of recording condition data from any machine with a goal to assess its performance and determine its health. Machine monitoring provides a reliable, consistent and high-quality stream of data to operators, maintainers, and engineers/designers.

The data can be used in a variety of ways, from adjusting production speed and maintenance schedules to improving future machine designs.

1. Data retrieval

Depending upon the complexity of the machine, the data collection process could range from simple observations made by a machine inspector up to a network of advanced sensors that automatically collect complex information about the subsystems and components of the machine.

Depending on what you want to track, some data has to be collected manually. For example, man-hours spent on maintenance, parts and tools used for the repair, visual inspection and troubleshooting notes are the types of data you have to collect by hand. The process can be partially automated by using a capable CMMS system.

The main focus of most machine monitoring systems is tracking machine conditions and its operational parameters. With suitable sensors, you can track parameters like pressure, flow, temperature, vibration, etc.

For example, monitoring bearing and coupling vibration in rotary machines as pumps or compressors can determine its current and future health, thus preventing unexpected downtime. Similarly, a rapid, unusual temperature change is often a result of increased friction, signifying a lack of lubrication and impending machine failure if not attended to in time.

A few other examples of data that can be recorded include, but are not limited to:

- Machine status: The monitoring system can give the machine’s status like ON/OFF, run rate, cycle start and stop, part complete, and machine speed.

- Product attributes: The product attribute would include physical and chemical characteristics of the product handled by the machine such as temperature, pressure, flow, vibrations, specific gravity, humidity, etc.

- Quality data: Includes data like First pass yield (FPY; indicates a line’s production and quality performance) and scrap rate.

- Reliability and availability data: Machine reliability and availability parameters along with machine utilization rates can also be collected automatically – such as machine energization and energization times, energy consumption, machine failure logs, and standby/layover times.

- Maintainability data: Knowing unplanned and planned machine downtime for specific machines can be very insightful. Maintenance teams can combine that data with maintenance metrics like MTTR and MTBF to evaluate the effectiveness of their actions, optimize their maintenance schedules, and calculate cost-effectiveness of used spare parts and machines.

- Energy consumption: Focuses on tracking electricity usage for each machine and the amount of energy that has been saved throughout the year.

What you end up tracking should be based on operational requirements, manufacturer’s recommendations, and machine reliability and maintainability requirements.

2. Data transfer

The magnitude of collected data can be overwhelming if not organized and stored in a secure place. To enable consistent interpretation and meaningful analysis, the real-time data has to be neatly and safely stored.

The advanced machine monitoring systems are cloud-based, which means that the collected data is sent through the (wireless) network and stored on a cloud server. This enables real-time tracking and analysis, which, among other things, creates the foundation for predictive maintenance.

An alternative method that some small manufacturers use for simpler machines is real-time data transfers within the machine’s internal hard disk as off-line machine logs. In this scenario, the operator has to regularly go to the machine and download logs for further analysis and direction.

While the offline logs obviously cannot produce real-time recommendations, they can be used by design engineers to analyze emerging failure modes and improve machine designs.

3. Data analysis

Once the data is collected and stored, it has to be analyzed to derive meaningful insights. The analysis is often performed automatically by predictive algorithms. They are written to analyze the incoming data and compare it with baseline and historical information to estimate future performance.

The analytics is then used to generate real-time operating and maintenance recommendations and warnings.

For example, a sensor on a CNC machine can provide real-time information about the intake current from the servomotor. In case of motor overload, it can send instant notification, cautioning the operator about the possible malfunction.

A smart approach is to merge several parameters into a single metric that defines the overall productivity of the machine – like Overall Equipment Effectiveness (OEE). The machine monitoring systems can be leveraged to calculate OEE in real-time, for all the critical equipment installed on the shop floor, and thus determine the overall effectiveness of the plant operation.

Benefits of machine monitoring systems

There are many benefits of sampling and understanding machine performance and condition data:

- Improved response time: Instant notifications can be sent directly to the machine operator whenever any abnormality is observed, reducing costly machine damage and minimizing unplanned downtime, thus meeting or exceeding machine reliability, availability, and maintainability requirements.

- Inventory and resource optimization: By measuring the amount of raw material that goes into the machine and the amount of fine product produced, you gain insight on machine losses, find new ways to eliminate waste, and optimize the inventory and resource consumption.

- Refined maintenance schedules: Machine condition information is essential for optimizing maintenance schedules and knowing how machines behave on the shop floor, as it accumulates data about machine health and performance in local conditions. This enables you to run predictive maintenance programs.

- Automatic data collection: Manual entry of machine data is time-consuming and prone to error. Automatic collection increases the overall quantity and quality of available data.

- Precise operations: Machine monitoring systems enable manufacturers to increase the machine accuracy and precision by analyzing operational parameters such as feed rate, tool paths, energy consumption, etc.

- Improved machine performance: Machine monitoring enables manufacturers to track various metrics that can later be used to improve OEE.

- Machine replacement and renewal decisions: What is the remaining useful life of your assets? When should you buy a replacement? Machine monitoring provides vital information for investment appraisals and machine replacement decisions, in addition to daily production management.

With that out of the way, let’s see what kind of hardware and software you need to set up a machine monitoring system.

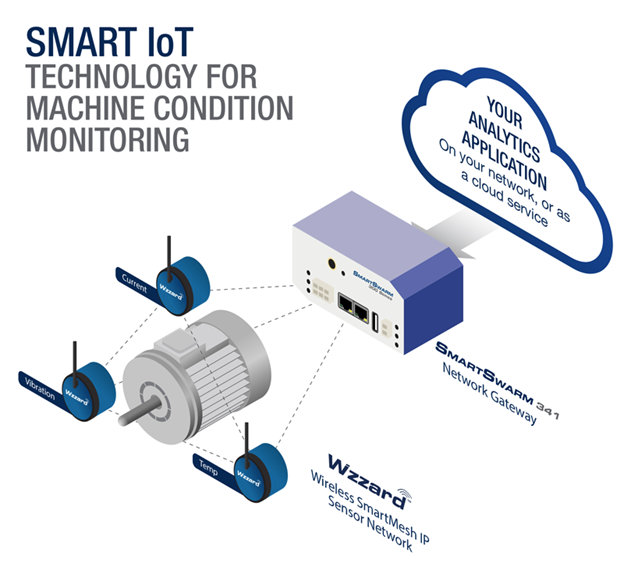

What technology do you need to set up machine condition monitoring?

All machine monitoring systems have a software and a hardware component. They have to work in harmony to enable effective monitoring. Hence, an effective implementation requires compatibility and integration of these hardware and software elements.

A representation of machine condition monitoring setup. Source: Advantech

Machine monitoring hardware

We can pick up both analog and digital signals for machine monitoring.

In its simplest forms, the analog monitoring system would include a simple oil-filled dial or meter that indicates the temperature or pressure of the product handled by the machine. Another example would be audio sensors that produce analog audio signals to monitor the sound of equipment.

The digital monitoring systems, on the other hand, would work with digital signals represented as ON or OFF, high or low, 0V or 5VDC, etc.

For example, a digital light sensor can be used to count the number of rotations (in other words, speed) of the induction motor. After further processing, motor speed data can be utilized to monitor other functional parameters such as rotor air gap, torque, and voltage.

At the very minimum, machine monitoring hardware will include condition monitoring sensors or relays, cables/modems/routers to set up (wireless) network and ensure data transfer, and internal servers and computers (if data is stored and analyzed on-premise).

Machine monitoring software

There are many viable cloud-based systems that can integrate with a large number of data sources. Depending on what you want to track and measure you can look for smart manufacturing platforms, Manufacturing Execution Systems (MES), dedicated OEE software, or IoT-enabled Computerized Maintenance Management System (CMMS).

While they are known to have some overlapping features, you can mix and match all of them for an even greater insight into the health and performance of your equipment.

These software solutions enable automation in data collection and processing. They also make information more comprehensible by presenting data in the form of easily readable graphs, charts, metrics, and sometimes even direct recommendations.

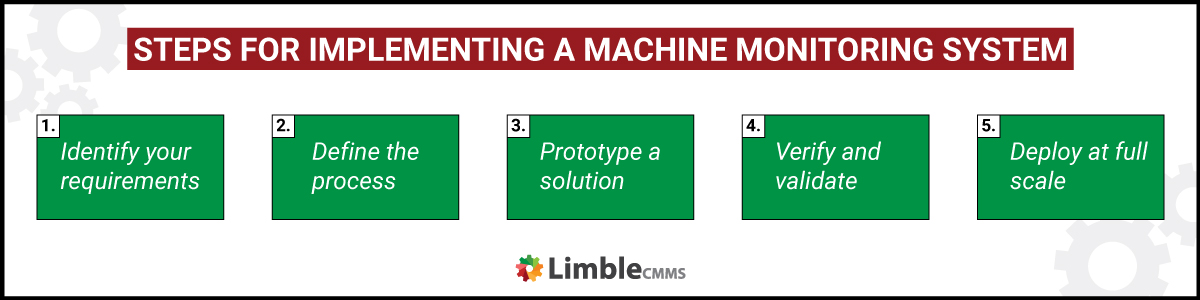

Steps for implementing a machine monitoring system

Below are some steps that can be adapted to implement a machine monitoring system. We will presume that all stakeholders have already given the green light to proceed with the project.

1. Identify your requirements

The first step is to identify the objective of a machine monitoring system for your plant. The machine monitoring for a CNC machine has different requirements and failure modes than a bottle filling mechanism on a converter belt.

Moreover, depending on the type of the machine and operational requirements, different parameters will need to be monitored. Some will require the deployment of expensive sensors, while others will be fairly economical.

At this stage, the budget and resources needed for the implementation must be presented, discussed, and approved.

2. Define the process

After that, you should define how the data will be collected, transferred, and analyzed.

Who will oversee the implementation and lead post-implementation improvements? Who will have access to the data and how will that data be used?

3. Prototype a solution

Once the requirements are identified and the process defined, the next step is to implement the prototype solution. The idea is to implement the solution on one machine or a small area of the plant, to make sure the results are coming out as intended.

It is a great way to sort out kinks before making big, plant-wide changes.

4. Verify and validate

After the pilot project has been running for a while, it is time to review the results. Have you been able to get the desired data? Has that data been accurate? Did it have the desired effect; did it help you improve the production and maintenance processes? Have engineers got useful data to improve product design and operational configurations?

If you are not satisfied with the results, it is plausible to completely scrap the current monitoring setup and test a totally different solution.

5. Deploy at full scale

Once the prototype is implemented and is producing the desired effects, it is time to mass-deploy the machine monitoring solutions for all the equipment similar to the prototype equipment.

Keep in mind that production processes are not set in stone. Equipment gets worn out, plant conditions change, new operators handle the equipment. Effective machine monitoring needs to adopt the principle of continuous improvement to match your evolving requirements.

The key to data-driven decision-making

Machine monitoring is much more than just an added feature. All in all, a machine monitoring system can help reduce operational costs, predict and fix arising equipment issues, maximize equipment uptime, and provide a platform for evidence-based and data-driven decision-making.

If you want to start with a simple condition-monitoring system, reach out to our team. They will be pumped to explain how Limble CMMS can help.