Sooner or later, every maintenance department will have to go digital. The goal of this article is to help you get there as soon and as smoothly as possible.

In this CMMS implementation guide, you will learn:

- How long does it take to implement CMMS software

- Step-by-step process that ensures successful implementation

- Common challenges you will encounter during the process (gathered by surveying our customer base)

- What can you do to avoid or solve those challenges (based on personal recommendations of different Limble customers)

Strap yourself in, we’re taking off.

An overview of standard CMMS implementation timeline

How long will it take to implement CMMS software at your facility?

The answer depends on multiple factors like the scale and complexity of your operations, how much time you need to gather and prepare data you want to enter into the software, and the level of training your maintenance team will need to get the hang of the software.

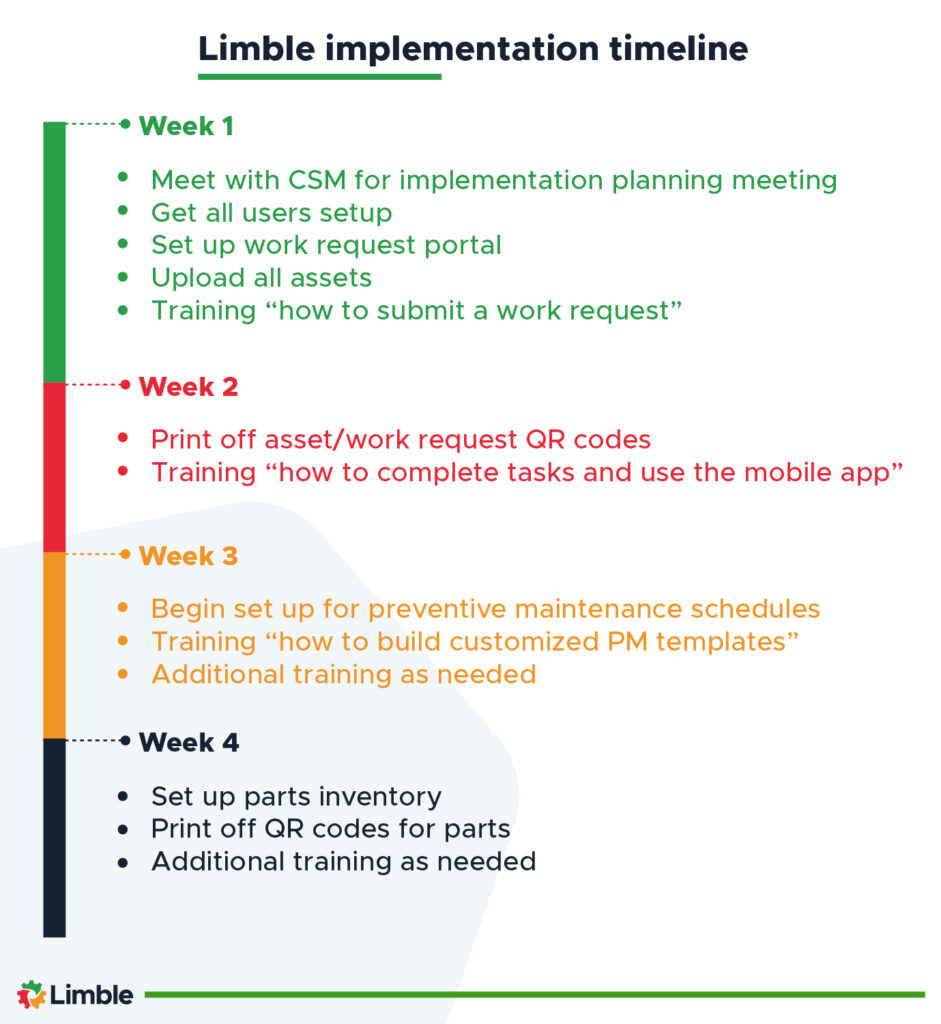

In the image below, you can see how mid-sized maintenance teams need about a month or so to fully implement Limble CMMS.

Keep in mind that Limble is very easy to use and doesn’t require a lot of training.

“It is so easy to get Limble up and running! Implementation was a snap, and our technicians really like having all the information they need right on their tablets — no more shuffling through paper work orders and reference materials.”

— John Patterson, Equipment Manager, Atlanta Athletic Club

“It only took, really, a week or so for the maintenance staff to get the hang of the software. Since then . . . I’ve seen an increase in productivity by about 20 to 30%.”

— Joe Romero, Director of Facilities, Myriad Genetics

“Setup was a breeze and my CMMS advisor was quick to respond with any questions I had.”

— Jeff Burnham, Ameritex Services

If you’re going with one of our competitors, you’ll probably need more time to set everything up and teach people how to use the software. Keep that in mind during project planning.

CMMS implementation phases

CMMS implementation process can be split into four distinct phases. Below, we provide a quick overview of each phase.

For a more detailed breakdown, download our step-by-step CMMS implementation guide.

1. Preparation and planning phase

Preparation and planning are key to avoiding project failure, delays, or unmet expectations. It is a good idea to outline a rough timeline for each of these phases.

Before taking any concrete steps, talk with your chosen CMMS vendor. Treat it like an opportunity to gain a broad understanding of a standard implementation process for their software, gather useful tips, and clarify timelines, roles, and responsibilities.

Take your new-found knowledge back for a meeting with your IT department. The level of their involvement will depend on whether you’re using a cloud-based or on-premise CMMS:

- For cloud-based systems, you’ll want to ensure hardware compatibility and adequate bandwidth.

- For on-premise installation, you’ll want to organize a technical alignment meeting between your IT department and your CMMS vendor to discuss software and hardware requirements. You might also need to purchase new servers or other assets.

As a final step in this phase, form a dedicated implementation team. Include key stakeholders from various departments such as IT, warehouse, engineering, and finance. The leader should ideally be someone with authority, like a maintenance manager or director.

2. Data gathering phase

Use your implementation team to define which data to transfer into the CMMS. We recommend starting with the most important information on your key assets and spare parts, then gradually adding less critical equipment, vendors, the rest of your MRO inventory, and everything else you deem useful.

Whether a spreadsheet or a database, aim to get all of the data into a single standard format. Devote time to thoroughly clean your data, removing duplicates, standardizing formats, and filling in any missing information in compliance with the character limits and formatting rules specified by your CMMS vendor.

Finally, define and standardize your data entry norms. Take a closer look at compliance with the CMMS’s internal structures, standards, and formats, as well as any relevant industry regulations and operating standards.

Establish standardization in:

- Data hierarchy

- Time and date formats

- Naming conventions (terminology, abbreviations, spelling, etc.)

- Character limits (will often be defined by the software itself)

- Decimal-point accuracy

- Mandatory vs optional fields

- How to deal with any custom data fields you plan to create and use.

3. Product implementation phase

Start the implementation phase with kickoff meetings involving your CMMS provider, implementation team, and workers to make sure everyone is on the same page and knows what to expect.

After time, it’s time to perform system configurations and train people to use the software.

Here are the steps we recommend taking, in sequential order:

- Perform basic system configuration: Includes things like adding users and setting up user roles, default currency, clock and time formats, etc.

- Upload assets: This can be done manually and/or in bulk. Most CMMS programs accept data for bulk uploading in a comma-delimited format (.csv file).

- Configure the work request portal: In Limble CMMS, you can build multiple WR portal versions for different purposes. All you have to do is select which details the person submitting a work request has to enter before clicking the “Submit” button. Be sure to provide instructions to employees on how to submit requests accurately and efficiently.

- Generate and print asset QR codes: Speak with your vendor representative to understand the best way to generate and bulk-print these codes and fix them to their respective assets. For reference, Limble CMMS will automatically generate QR codes when assets are uploaded.

- Train technicians on how to use the mobile app: You’ll want to teach them how to retrieve assigned tasks, update the work card status, order spare parts, close completed tasks, and similar.

- Set up preventive maintenance schedules: Having loaded your assets into the CMMS, it’s time to develop preventive maintenance schedules and tasks for each asset, determining the frequency and priority of each task.

- Train senior maintenance personnel to build PM templates: Explain the basics, like creating the tasks from scratch vs. copying an existing template. Discuss available functionalities (checkboxes, text boxes, dropdown menus, file attachments…) and make sure everyone gets enough hands-on practice.

- Set up parts inventory: After you enter spare parts and consumables into your CMMS, you’ll usually have the option to create a minimum and maximum stock holding and define automatic reorder points.

At this point, you will have everything you need to start actively using the software, incorporating it more heavily in your everyday workflow.

In parallel, have a designated person that will take care of the remaining data entry. This includes remaining parts and assets, supplier and contractor information, historical maintenance data, user manuals, and other non-critical maintenance information.

4. Post-implementation phase

The CMMS implementation process isn’t done when you have all of your data in — it’s done when everyone knows how and uses the software correctly.

You’ll want to perform quick weekly audits in the first few months after implementation to identify and weed out any bad practices before they become entrenched. If needed, appoint system champions who can assist staff members that are struggling with your system or new maintenance workflows.

Lastly, if you haven’t done so already, set up your maintenance dashboard and reports based on the maintenance KPIs you want to track. Here is a short video that explains how you can set up a custom dashboard and reports inside Limble:

The most common CMMS implementation challenges (and how to manage them)

Some organizations have a smooth transition process when digitizing their maintenance operation. Others experience a very bumpy road. Most fall somewhere in between.

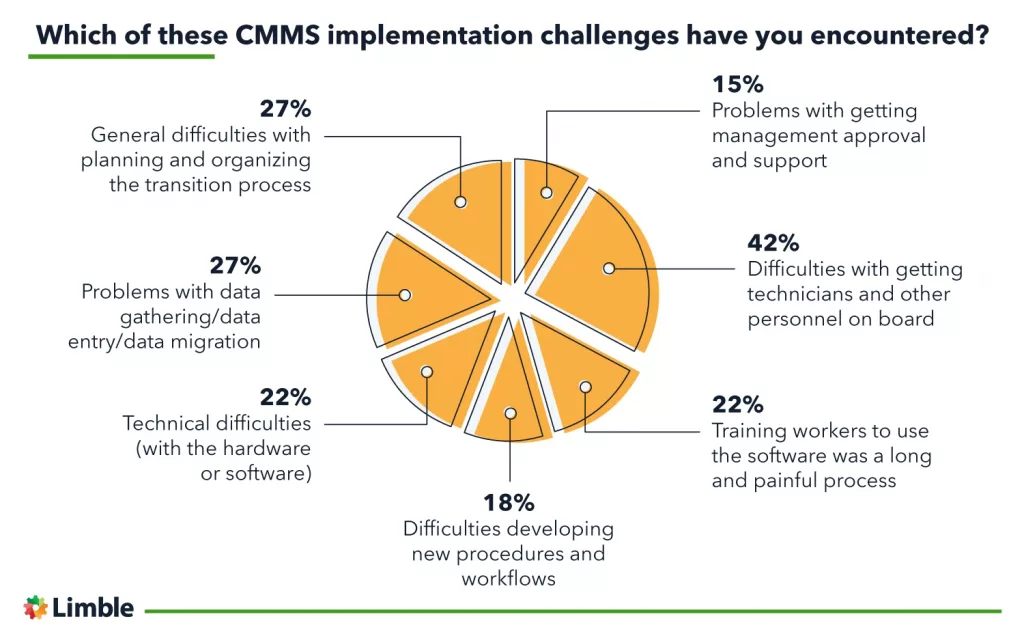

Here is what Limble CMMS users reported in our internal survey:

1) Difficulties getting maintenance personnel on board

Older technicians that are less tech-savvy are rarely thrilled about your brilliant idea to implement CMMS software. And that is only natural. However, getting maintenance personnel on board is crucial. CMMS is extremely useful, but only when people commit to learning how to use it.

Here are some things you can do to get different stakeholders on board:

- Include the maintenance personnel in the review process when selecting your maintenance software. This will give technicians and mechanics some ownership of the process and expand the time window they have to get on board with the idea.

- Choose software that is easy to use. Trying to implement maintenance software that requires months of training is the most common reason why CMMS implementations fail.

- Demonstrate how CMMS will make their life easier and offer continuous support. A good CMMS is going to help eliminate or downsize many of the problems your maintenance personnel are regularly complaining about. Your job is to explain how and assure them that the implementation will have a reasonable pace everyone can follow.

2) Data management challenges

Having quality (accurate and up-to-date) data is paramount for optimizing maintenance operations, reducing downtime, and cutting unnecessary costs.

It can take a while to gather all of the relevant information and enter it into the software. Here are a few tips to help speed up the process:

- Streamline data-gathering processes. Decide which data you actually need (data you will actually use). Define where and how the data will be stored during the gathering process.

- Standardize data entry standards. Define which fields need to be populated (compulsory fields) and how (naming conventions, abbreviations, data formats, etc.).

- Clean up the data before entering it into the software. If you’ve gathered data from multiple sources, there is a high chance you have some overlapping, outdated, duplicate, or straight-up inaccurate data. Do a quick audit before data migration.

3) General difficulties with planning and organizing the transition process

Balancing the transition without compromising existing maintenance schedules and ongoing work that needs to be performed will require some planning. This especially holds true in the production environment, where KPIs usually dictate that the show must go on and you can’t just push tasks to the deferred maintenance backlog.

The exact steps to take vary from organization to organization and could be an article for itself. Still, we can leave you with a couple of general tips:

- Delegate work to experienced maintenance personnel. List out everything that needs to be done. Split tasks between experienced personnel.

- Someone has to actively lead the charge. The point is self-explanatory. As a maintenance or facility manager, this responsibility will likely fall on your shoulders.

4) Difficulties developing new procedures and workflows

You can look to adjust your workflow based on how the software is set up, or you can look to adjust the software based on how you want to work. A mixed approach usually works best. The CMMS system will generally push you to follow industry best practices, but it should still be flexible enough to adapt to the specific needs of your facility.

Here’s what you can do:

- Let the software guide you. If you do not know where to start, let the software guide your workflow.

- Write or update your SOPs. It is never a bad time to document your maintenance procedures. Save them in your CMMS so they are easily accessible and use them while onboarding new techs and mechanics.

- Cut out wasteful actions and unnecessary procedures. CMMS will automate some administrative work. Still, there are bound to be additional actions and procedures that add no value. Use this chance to create a leaner maintenance department.

- Aim for incremental improvements. You can’t change 40% of procedures from this to next week and not expect any problems. Focus on setting up core processes like work requests, work orders, and parts inventory management first.

5) Training workers to use the software

The level and volume of training your team will need to go through will depend on two main factors: how easy-to-use the software is and how proficient your techs are with using technology in general.

Here are some tips to get you on the right track:

- Consider all training options. One-on-one training, setting up a classroom-type environment to demonstrate different features, written guides, video tutorials, self-demo, (online) demos from the vendor – there are many training options you can opt-in for. Mix and match them according to your needs.

- Evaluate individual needs. Different people will need different levels of support. Refer to the options outlined in the point above.

- Ask the vendor for support. They know their product the best – let them teach you how to use it and adjust it to fulfill the needs of your facility.

6) Problems with securing management approval and support

CMMS implementation, along with its pricing, is bound to introduce major changes into your maintenance department and plant floor. It is not a project you want to go into with a “maybe”. Top management needs to be aware that this is an ongoing process which needs to be properly supported (with funds and rhetoric alike).

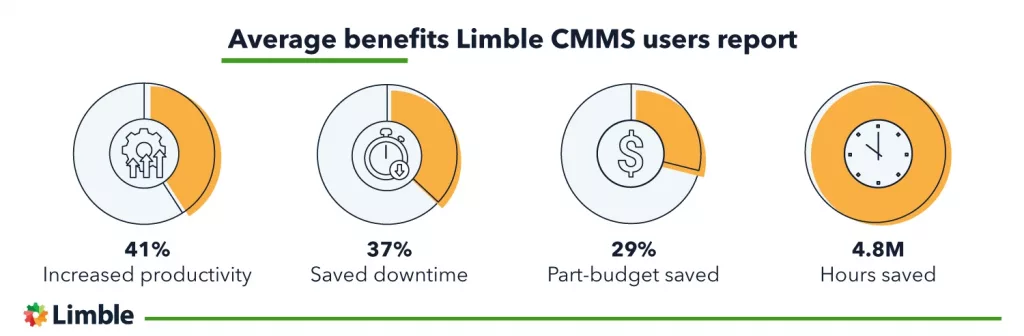

The best way to gain management approval is to talk about benefits, with a focus on ROI and cost reductions.

For instance, below are the benefits and cost savings that an average facility experiences after a successful CMMS implementation and using Limble for 6+ months.

To help you define the actual numbers, we would like to refer you to our CMMS savings calculator. Alternatively, check out this CMMS ROI guide.

7) Technical difficulties with the hardware and software

Cloud-based solutions like Limble which do not have to be installed on your internal servers are less likely to come with major hardware or software issues. Certain problems can still happen, and when they do, your vendor should be ready to offer prompt support.

We made sure that our customers always get prompt support — and we have badges to prove it!

“…their customer support is fantastic, almost 24/7. They reply within 10 mins anytime. I am sure that Limble will really help your operations.”

— Natee Singhaputtangkul, Managing Director, Swift Dynamic

“I have tried and tested at least 5 different CMMS systems before trying Limble, and I must say I haven’t come across something as intuitive yet powerful as Limble CMMS. There are three features that will make me recommend this to anyone: The robustness of the system, ease of use, AND the customer service.”

— Mohammad Hassaan Akram, Unilever

How to get started with Limble CMMS

We hope this guide gave you a good overview of the CMMS implementation process.

If you are interested in testing Limble CMMS, you have three options:

If you have any additional questions about Limble’s implementation process or features, don’t be afraid to reach out via email.