Contrary to how it sounds, deferred maintenance can be useful. It just depends on how you use it.

Maintenance managers often work with limited resources. At some point, you will have more work to do than you can manage. This will force you to postpone maintenance tasks and put them into a maintenance backlog to be completed later.

If used strategically, deferred maintenance can help you prioritize maintenance tasks, helping your team achieve more. We’ll show you how to do it right.

5 Steps to decreasing your deferred maintenance backlog

If you have an overwhelming deferred maintenance backlog, some things will have to change. Here are five steps you can use to set up an efficient workflow that will reduce your maintenance backlog.

Step 1: Create a list and gather the necessary information

Before you can implement any concrete measures, you need to ensure your maintenance backlog consists of a clean and accurate list of deferred tasks.

Having the right information ready will give you a clear view of the work ahead of you.

Create one central list for all backlogged tasks:

- If you are using multiple documents and spreadsheet, combine them into one.

- Encourage your team to add any additional outstanding work orders or issues that have not been reported.

Gather necessary detail:

- Estimate the resources (time, specialized skills, spare parts, budget) needed to complete each task.

- Refer to equipment maintenance logs or documented history to fill in any gaps.

Step 2: Calculate ROI and prioritize critical tasks

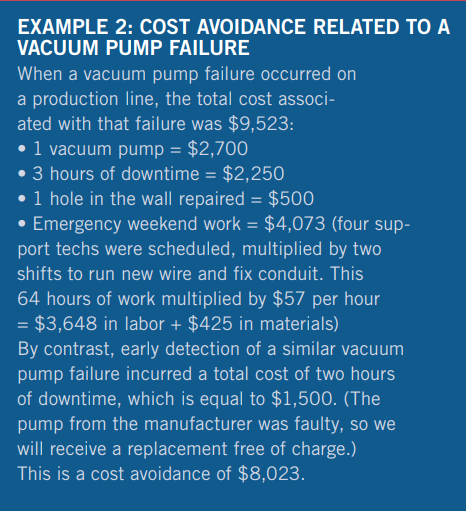

Now it is time for prioritization. Calculating an ROI (return on investment) is a great way to begin.

When you estimate the impact of incomplete maintenance and compare that to the time, money, or other resources required to complete that maintenance, the priority level becomes clear.

Here is an example from Plant Services’ guide on how to calculate maintenance ROI.

Step 3: Allocate resources

Next, assign the outstanding tasks to your team members, beginning with those tasks that provide the highest ROI (typically these are the highest criticality, lowest cost tasks). If assigning tasks to your team members is a simple task for you, congratulations! You are one of the lucky few.

If not, we aren’t surprised. Allocating resources might be the most challenging step, simply because a lack of resources is often the main culprit behind your maintenance backlog anyway.

You are likely to need additional resources to tackle your maintenance backlog within an appropriate amount of time. Yet, it is not a secret that upper management hates being asked for money, especially from the maintenance department.

Come into this conversation prepared with your ROI calculations. This will demonstrate how providing more resources will actually save the company money in the end. For instance:

- If asking for more staff or technicians, bring data on the number of work orders received and completed on a weekly basis, as well as overtime costs that could be avoided.

- If asking for additional funding, bring data on asset history, breakdowns, and losses that occur as a result of using poor quality parts.

Hopefully, you have a CMMS that has this data readily available to support your case.

Step 4: Reorganize and implement preventive measures

Maintenance budget issues aside, the most common reason for having to delay maintenance tasks is simply doing too much reactive maintenance. Waiting to put out fires as they come up means you are likely to keep diverting resources and adding to your deferred maintenance backlog.

One way to prevent that from happening is to start implementing preventive measures. Review our in-depth guides on how to switch from reactive to preventive maintenance and how to develop a preventive maintenance program.

If you’re already in the transition process and looking at how to optimize your PM plan, check out our checklist below.

Here are some other operational changes you can make to increase efficiency on your team:

- Change how work orders are tracked to ensure they are assigned and completed efficiently

- If you don’t have a CMMS, try to a communication app to share important information more efficiently

- Set-up a clear chain of communication so people have the necessary resources for questions and issues

Step 5: Execute a maintenance strategy with the help of a CMMS

Running an efficient maintenance team without any software support is difficult, if not impossible. With all the flexibility and workflow optimization benefits that come with a mobile CMMS, your limited resources can stretch a lot further.

- Higher productivity (less administrative tasks, faster information flow)

- Improved communication (instant notifications, easier technician collaboration on-site and off-site)

- More accountability (who did what and how long it took to complete)

- Better organization (easily creating a preventive maintenance plan, simple tracking and assigning of work)

- Increased data accuracy (inventory control, work schedule overview, usage rates, asset history, etc. – accurate reports drive informed decisions)

For an in-depth look at CMMS check out our detailed CMMS guide.

At the end of the day, maintenance software was developed with the sole purpose of helping maintenance professionals be more efficient. If you struggle with deferred maintenance and you don’t use any maintenance software, you should seriously consider upgrading to one like Limble CMMS.

Consistency is key

A deferred maintenance backlog won’t disappear overnight, but with consistent work and a smart maintenance strategy, you should be able to keep it under control.

If you are interested in other ways in which Limble can help improve your maintenance department, don’t hesitate to get in touch, we’re always up for a chat.