Maintenance workers are the core of every maintenance department. In one way or another, their actions are responsible for maintaining the physical environment we work and live in.

We like to say that maintenance staff are unsung heroes because they rarely get the praise they deserve. What they do is essential for ensuring business continuity and operational excellence.

Without beating around the bush, we’ll cover what it takes to be a maintenance worker, how to write a proper maintenance worker job description, and how much maintenance workers make for their time and expertise.

What is a maintenance worker?

A maintenance worker is a person tasked with the maintenance and repair of physical assets and infrastructure.

When someone talks about a maintenance worker, they usually think of a maintenance technician, maintenance mechanic, electrician, cleaning staff, or similar.

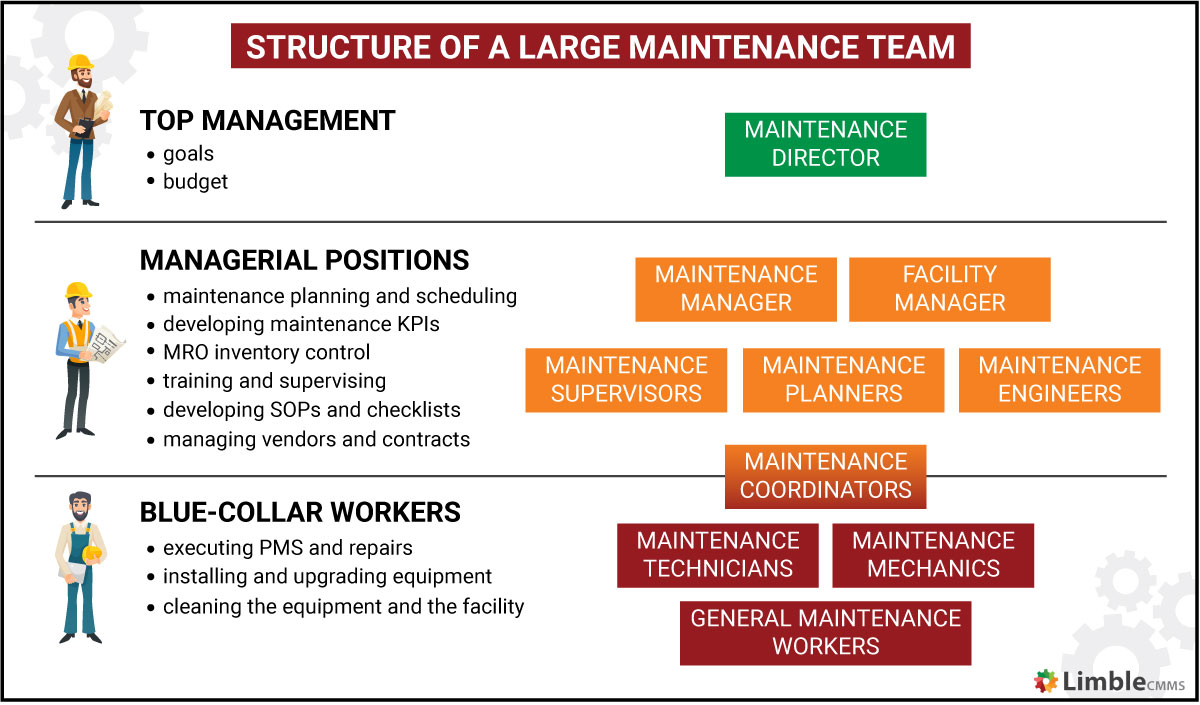

If we consider the term maintenance worker in a broader sense, we could technically include other members of the maintenance staff like maintenance managers, coordinators, planners, or supervisors. However, “worker” is an expression that is more often used to describe someone that executes tasks, rather than someone who assigns them.

What does a maintenance worker do?

The exact day-to-day workflow of a maintenance worker can vary dramatically.

Depending on the type of organization the maintenance worker is employed at and the type of machines he is responsible for, he will be exposed to different working conditions, take different safety precautions, travel to one or multiple locations, and follow different workflows.

Let’s check a few examples (this is by no means a definitive list):

- Performing building maintenance for commercial or residential properties: Building maintenance workers will spend most of their time evaluating, maintaining, and repairing building systems (electrical, HVAC, elevators, plumbing), infrastructure (doors, windows, walls, roof…), and even some groundskeeping tasks.

- Maintenance workers in a manufacturing plant: Maintenance technicians and mechanics solve mechanical, electrical, and hydraulic issues on various production and facility equipment, (dis)assemble/install new machines, troubleshoot mechanical equipment breakdowns, and similar. Work conditions change depending on what is being produced at the plant.

- Maintenance staff on a mining/construction site: Maintenance workers in heavy industries perform inspections, preventative maintenance, troubleshooting, upgrades, and repairs on heavy equipment. They often work in dusty, humid, and heated environments.

- Maintenance workers in a transportation company: They perform routine and corrective maintenance tasks on select vehicles and equipment. They occasionally need to go out in the field to execute certain tasks.

- Workers that maintain electrical grids: These are maintenance workers that have to spend most of their time out in the field, which is why they are often called field technicians. Naturally, they need a high-level understanding of electrical systems and specific safety training.

While different industries ask for a different set of technical skills and knowledge, the core responsibilities of a maintenance worker remain the same across all organizations:

- general upkeep and minor repairs

- perform routine maintenance, preventive maintenance, and corrective maintenance

- diagnose and repair broken assets

- maintain a record of performed maintenance tasks

- keep hand tools, power tools, and supplies organized and clean

- follow safety precautions and adhere to the schedule

Maintenance Acronym Guide

Confused by PMs, MTTR, and DFMEA? This maintenance acronym guide will have you talking the talk in no time.

Examples of maintenance worker job descriptions

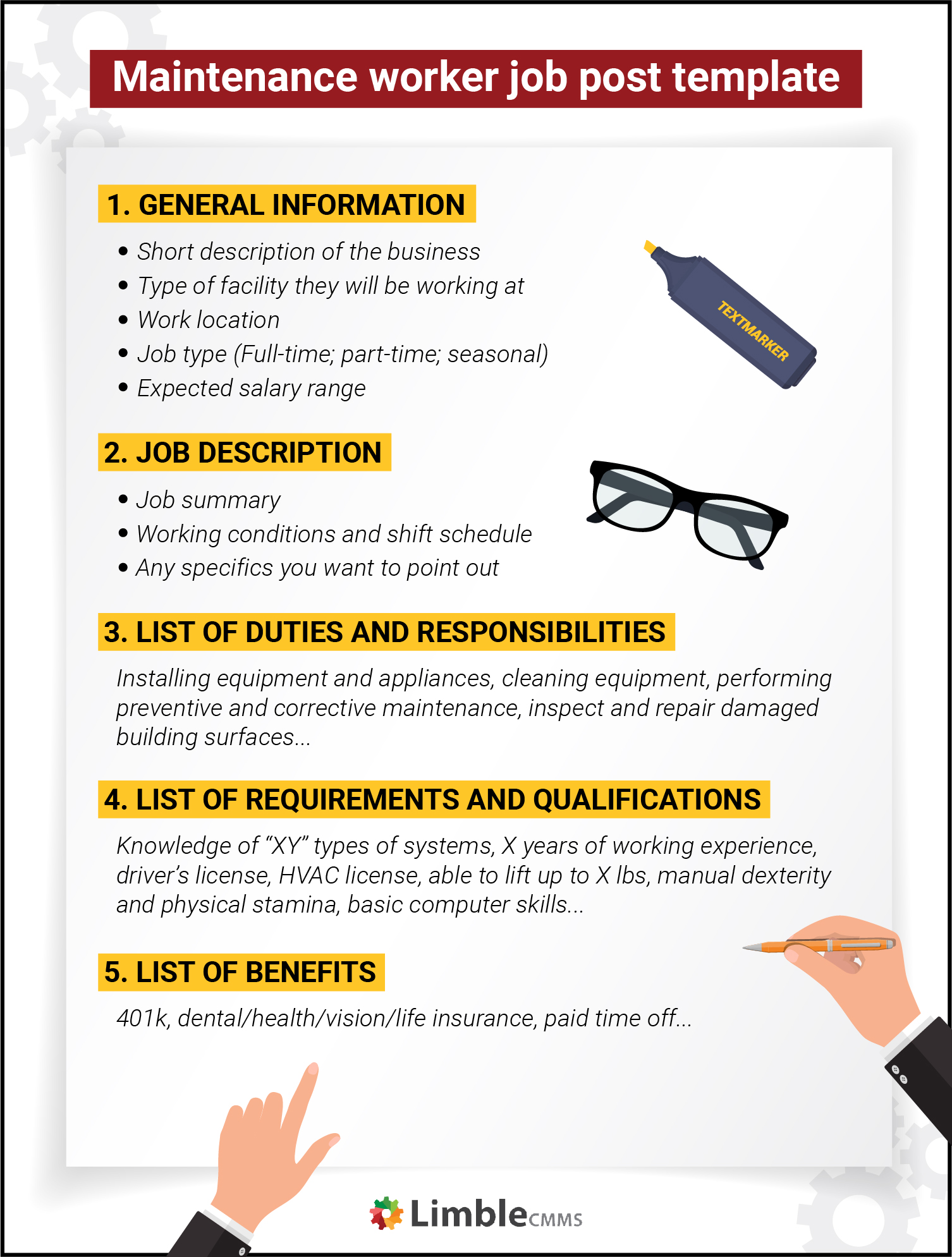

If you’re looking to write a job post for a general maintenance worker, here are some templates you can use for inspiration:

There are many free and paid maintenance worker job boards where you can go to post a job or review open job postings.

Maintenance worker salary | How much does a maintenance worker make?

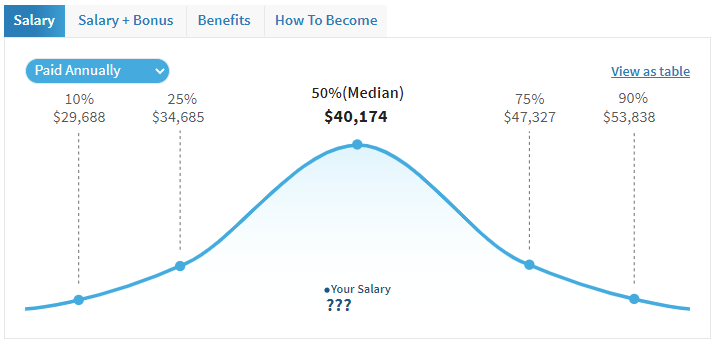

Maintenance worker salary ranges can vary widely depending on many important factors, including education, certifications, additional skills, years of work experience, location, and the size of the organization they work at.

The most straightforward way to estimate how much does maintenance staff make is to look at the aggregate values at big job finding and salary-related platforms (below are yearly salaries for full-time general maintenance workers in the US):

- Glassdoor put the average base pay at $40k

- PayScale has the average base salary at $33k

- Salary.com lists the average base pay at $40k

When translated into hourly pay, general maintenance workers are compensated $10 to $20 per hour. Keep in mind that those numbers reflect the base pay and do not include bonuses, overtime pay, and any additional benefits that come with the job.

What are good skills to have as a general maintenance worker?

Let’s see which characteristics can be found in a skilled general maintenance worker.

Broad technical knowledge

Unless working for a company that provides maintenance for one specific type of machine, a maintenance worker will need to perform all kinds of routine maintenance and repairs on many different assets. Having broad technical knowledge will allow them to handle most of those tasks.

Over time, maintenance staff is expected to get familiar with the type of assets at their workplace so they can perform more complex maintenance activities. Having a strong foundation will help them acquire that knowledge faster, but this is not something that happens overnight.

Problem-solving skills

An integral part of maintenance work is the process of diagnosing and repairing broken assets. Every asset can have a bunch of different failure modes and reasons for why it failed. Finding the exact cause of failure requires good problem-solving skills.

On top of that, some failures are caused by the misuse of the equipment or because of the usage of low-quality materials and spare parts. Fixing those kinds of failures might involve solutions that can’t be found in an OEM manual. The maintenance worker might need to improvise the solution on the spot to get things going until the organization can apply a better solution.

Only skilled maintenance staff members that know all the nooks and crannies of a particular asset will be able to do that. These types of workers are extremely valuable for the maintenance department and the organization as a whole.

Physical stamina and dexterity

Being a maintenance worker is not a desk job. This position can be physically demanding. One should expect to carry and lift heavy items, spend most of their shift on their legs, and spend prolonged periods in awkward positions while performing specific maintenance work.

Working conditions can also be quite “colorful”. In the best-case scenario, a general maintenance worker will work normal hours in a safe and clean environment. However, more often than not, technicians and mechanics are required to work night shifts, clock in a certain amount of overtime hours, and crawl into wet and dusty spaces. If they end up working in things like poultry plants, their sense of smell will also need to go through an adjustment period.

In all of those scenarios, maintenance staff should be ready to get their hands (and clothes) dirty.

Speaking of hands, another great characteristic to have in a maintenance worker is a steady and precise hand. Maintenance workers will not exactly diffuse bombs, but installing sensitive machine parts and dealing with electrical wiring is not for clumsy people.

Basic computer skills

According to various statistics, every other manufacturing plant already uses a CMMS system or EAM software. What that means for maintenance staff is that using those tools will be a big part of their daily work.

Modern CMMS software should be easy to use and include a simple app that can be installed on any mobile device. Good user experience and intuitive navigation are important so even older technicians that are not the most skilled with new technology can quickly get the hand of the software. It is up to maintenance managers and their teams to choose the best maintenance software for their needs.

Moving forward, trends show that maintenance departments plan to increase investments into condition monitoring technology and predictive maintenance. While not directly tied to computer skills, new maintenance workers should have a general idea about how CBM and predictive maintenance work, as well as be trained to use different condition monitoring equipment.

Available certifications for maintenance staff

The majority of general maintenance workers have a high-school diploma. Those that have certifications on top of that are more likely to get hired and promoted. There are a few organizations out there that offer educational courses and training before the certification exam. Other certificates are strictly test-based.

While there are a few certifications that can be earned through online courses and exams, most will require some form of in-person testing.

Different industries look for different certifications so maintenance workers need to find programs that are relevant to their specific trade.

General certifications for maintenance staff members

IMI Certification

The International Maintenance Institute’s Certification provides a structured curriculum for continuing education and internationally recognized, industry-wide credentials that identify the certificate holder’s level of maintenance knowledge and skills. All IMI certifications expire after two years and workers have to re-certificate.

Certified Maintenance & Reliability Professional (CMRP)

CMRP is the leading credential for certifying the knowledge, skills, and abilities of maintenance, reliability, and physical asset management professionals. The CMRP is accredited by the American National Standards Institute (ANSI), which follows the globally recognized ISO standards for its accreditation purposes.

Certified Maintenance & Reliability Technician (CMRT)

CMRT is a credentialing program for the knowledge, skills, and abilities of maintenance and reliability technicians. The certification assesses the knowledge and skills of those responsible for preventative, predictive, and corrective maintenance. These multi-skilled individuals play a critical role in the success of organizations worldwide.

Facility and property maintenance certifications

Building Systems Maintenance Certificat (SMC)

The program provides in-depth information on key building principles, including efficient energy management and water treatment. It helps technicians to gain a better understanding of HVAC, plumbing, and other building systems that work together to provide a comfortable indoor environment. The training and the certificate are provided by BOMI, an international provider of educational products and services to the property and facility management industries.

Certified Maintenance Employee (CME)

This is an online program that presents general hospitality knowledge and soft skills needed in the hospitality industry, along with concise instructions for training new or prospective employees on how to perform the key tasks correctly. It is provided by American Hotel & Lodging Educational Institute (AHLEI).

Certificate for Apartment Maintenance Technicians (CAMT)

This course acts as an introduction for a new maintenance tech or as a refresher for the veteran professional, teaching what it takes to run a cost-effective maintenance program. The included modules cover the apartment business, electrical, appliance maintenance and repair, HVAC, plumbing, and maintenance and repair of the interior and exterior of apartment properties. CAMT program is accredited by the American National Standards Institute (ANSI).

Certified Building Operator

Building Operator Certification (BOC) is a training and certification program for building engineers and maintenance personnel. Its graduates learn how to make buildings more comfortable, efficient, and environmentally friendly.

HVACR Certification

HVAC certification license provides proof that HVAC technicians are trained and qualified enough to perform installation and repair tasks within their state. Technicians can become certified after passing exams that test a technician’s knowledge of the trade.

There are many other maintenance certifications for specific systems and industries. We focused on the ones that general maintenance workers are easily eligible for. For the same reason, we avoided certifications for job titles like maintenance and facility manager and supervisor. Such certifications often require a few years of experience in a specific role before one can access the certification program.

Key takeaway

Being a maintenance worker can be a demanding and dynamic job. As skill requirements and working conditions change from job to job, the employer and the potential employee should both be very clear about their expectations during the negotiation process.