$479M

Saved in annual downtime costs

30%

Avg. downtime reduction

$281M

Saved in annual parts spend

Learn Why Limble Is The CMMS Leader

Limble is trusted by 50,000+ maintenance professionals globally

Modular IoT Predictive Maintenance

Increase your ROI by tenfold with minimal time and financial investment.

- Plug-and-play condition monitoring sensor setup

- Instant alerts when sensor levels reach trigger thresholds

- Automatic logging of machine monitoring data

“We got it and we haven’t looked back. Best decision we have ever made.” – Carlos Melendez, Maintenance Supervisor, Tara Manufacturing

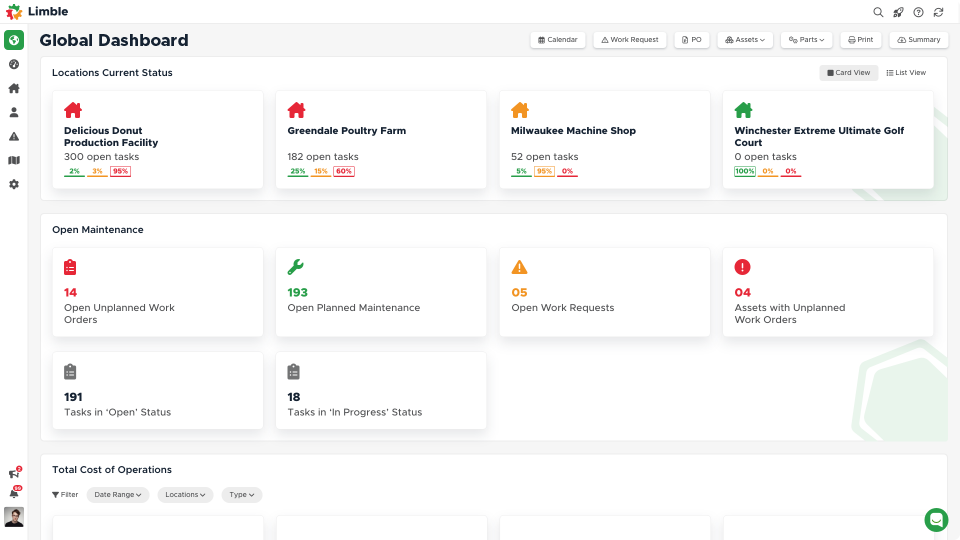

Real-Time Actionable Insights

Gain visibility into asset condition and lifecycle with automated reporting that predicts equipment failures before they happen.

- Get real-time actionable data on asset condition and failure modes

- Perform root cause analysis to assess and prevent future failures and downtime

- Build proof-of-concept maintenance strategies without breaking the bank

“Limble is the flat-out best maintenance program you could possibly have.” – Matt Burtz, Maintenance Director, Preferred Popcorns

Harness Predictive Data for Maintenance

Level-up your preventive maintenance strategy with machine data that enables continuous improvement.

- Identify optimal routine maintenance windows based on usage and productivity data

- Support lean production principles with data-backed PM schedules

- Automatic triggering of maintenance tasks

“The wonderful thing about Limble was it was just so darn easy to get implemented to a point where it really started adding value.” – Dustin Law, Engineering Manager, Western Pulp

Compare Pricing

Basic

Standard

Premium+

Enterprise

Tara Manufacturing

This family-owned manufacturing company turns the tide on downtime with a maintenance program powered by Limble.

FAQ

What is CMMS software?

CMMS (Computerized Maintenance Management System) software helps businesses manage, automate, and streamline all of their maintenance operations. Learn more about CMMS.

Who uses CMMS software?

CMMS software is used by anyone who manages maintenance — facility managers, operations managers, and asset managers, and more — to manage assets, schedule maintenance, and ensure safety. It is widely employed in industries including manufacturing, education, energy & utilities, food & beverage, and many more to maintain infrastructure and manage resources effectively.

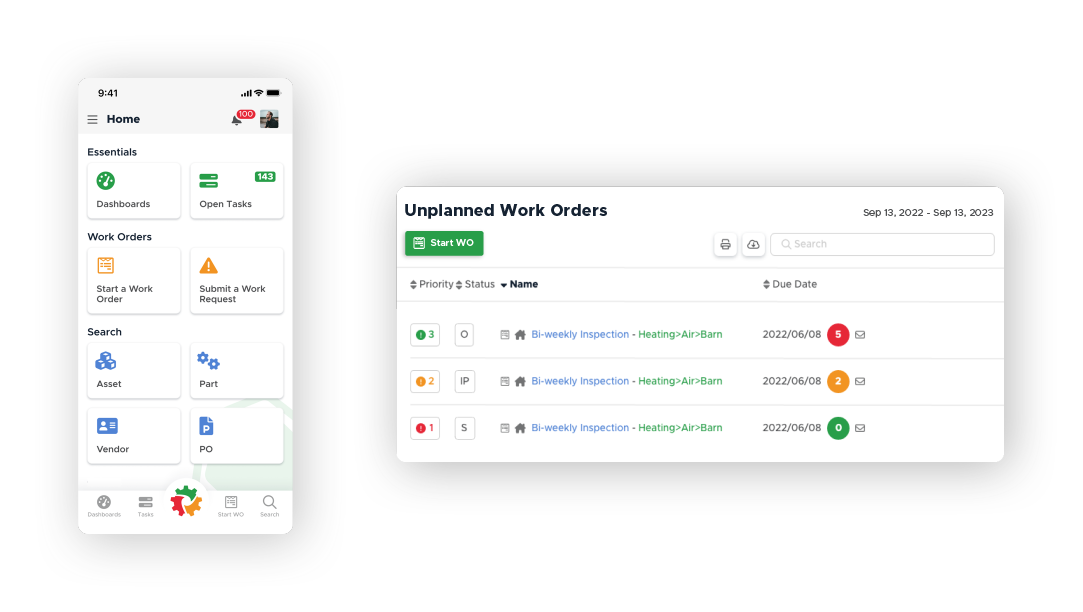

Is Limble Mobile CMMS app user friendly?

Limble is consistently rated Easiest-to-Use CMMS on review sites like G2, Capterra, and Software Advice. And our customers agree. With our mobile CMMS app, teams experience 30%+ better productivity, on average, requiring little to no training or ramp-up time. Our CMMS app can travel with your team, no matter where they go! Visit our App Store or Google Play for more information.

Can I connect to other systems?

Limble provides seamless, pre-built CMMS Integrations with the most widely used software systems. That means you won’t need help from a developer or your IT team to get started. Learn more about our integrations.

How secure is the Limble CMMS platform?

At Limble, our world-class data security practices ensure your account information is safe. We use state-of-the-art technologies and industry best practices to maintain a secure infrastructure, including SOC-II Type II certification, regular penetration testing, and continuous security training for our staff.

TRUSTED BY 50,000+ PROFESSIONALS AROUND THE WORLD

All-in-one CMMS for all your Maintenance Needs

Work Orders & Requests

Organize work orders, PMs and other tasks for your entire team. Easy-to-use mobile apps your technicians will actually use.

See Work Order SoftwarePreventive Maintenance Programs

Automate preventive maintenance scheduling, build simple checklists, and analyze team performance and efficiency.

See Preventive Maintenance SoftwareAsset Management

Intuitive and flexible asset management features make it easy to manage your assets, whether you have 10 or 10 million.

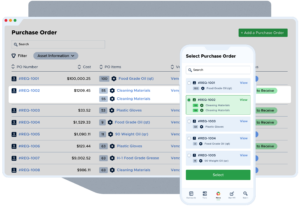

See Asset Maintenance Management SoftwareSpare Parts Inventory

Eliminate the guesswork and reduce the amount of time and money spent searching and managing your parts inventory.

See Parts Inventory Software

![5_Best_Predictive_Maintenance_Techniques[1] Predictive Maintenance Techniques](https://limblecmms.com/wp-content/uploads/5_Best_Predictive_Maintenance_Techniques1.jpg)