Equipment maintenance history records contain crucial data you need to optimize your asset management efforts.

In this article, we will show you how to utilize your maintenance records to reduce costs, pass audits, find problems, improve equipment reliability, and much more.

What is maintenance history?

An asset’s maintenance history is a repository of maintenance tasks you have performed on that asset over time. Think of it as a compilation of maintenance logs for a specific piece of equipment.

These days, maintenance service history is typically stored within EAM or CMMS software. However, it can also come in the form of paper records crammed into a filing cabinet.

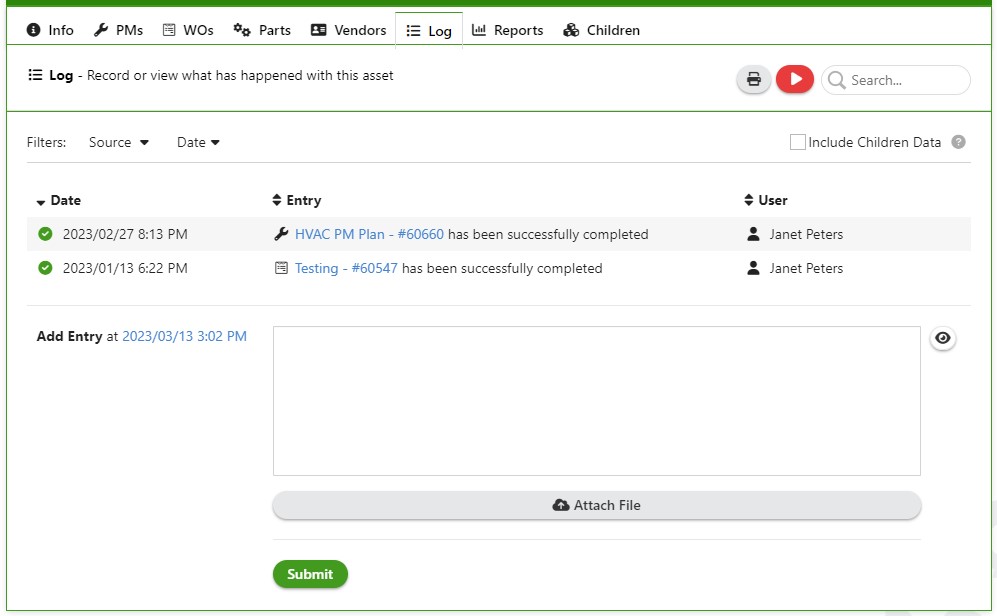

Example of maintenance history records for an HVAC inside Limble CMMS.

The exact information you find in your maintenance records will depend on the data points you decide to track. If you’re using maintenance software to plan and schedule work, you can see:

- When a certain maintenance task was scheduled for a specific asset

- Who scheduled it

- A description of the task or checklist

- Who completed the task and when

- How long it took to perform the task

- Which spare parts were used

- Notes and images logged by the person who performed the task.

This information has many different use cases. We discuss some of them below.

The Essential Guide to CMMS

Download this helpful guide to everything a CMMS has to offer.

11 ways to utilize your maintenance records

Here are 11 ways to get the most value out of your maintenance history records.

1) Use maintenance records for budget planning

While it provides immense value, maintenance comes with planned downtime and money spent on spare parts, manpower, and troubleshooting.

A detailed maintenance history will help you break down and understand those costs, enabling you to forecast and justify your maintenance budget for the coming year.

You can also use the historical records to predict when maintenance-related capital projects will need to happen and how is that going to impact your profit.

Example: It costs $1,500 to hire a specialist and pay for spare parts to maintain your skiving machine. You plan it during August, your high-profit month, to offset the cost.

2) Identify problematic assets and areas

Almost every production facility will have a machine that’s siphoning more money than it’s worth. This could be a legacy machine or a brand-new one that’s going through trials and optimization.

In either case, your maintenance history records will show you how much money you’re spending to keep each asset running. Perhaps your old oil heater is failing so often that you’ll save money by replacing it — using historical maintenance records to support that course of action.

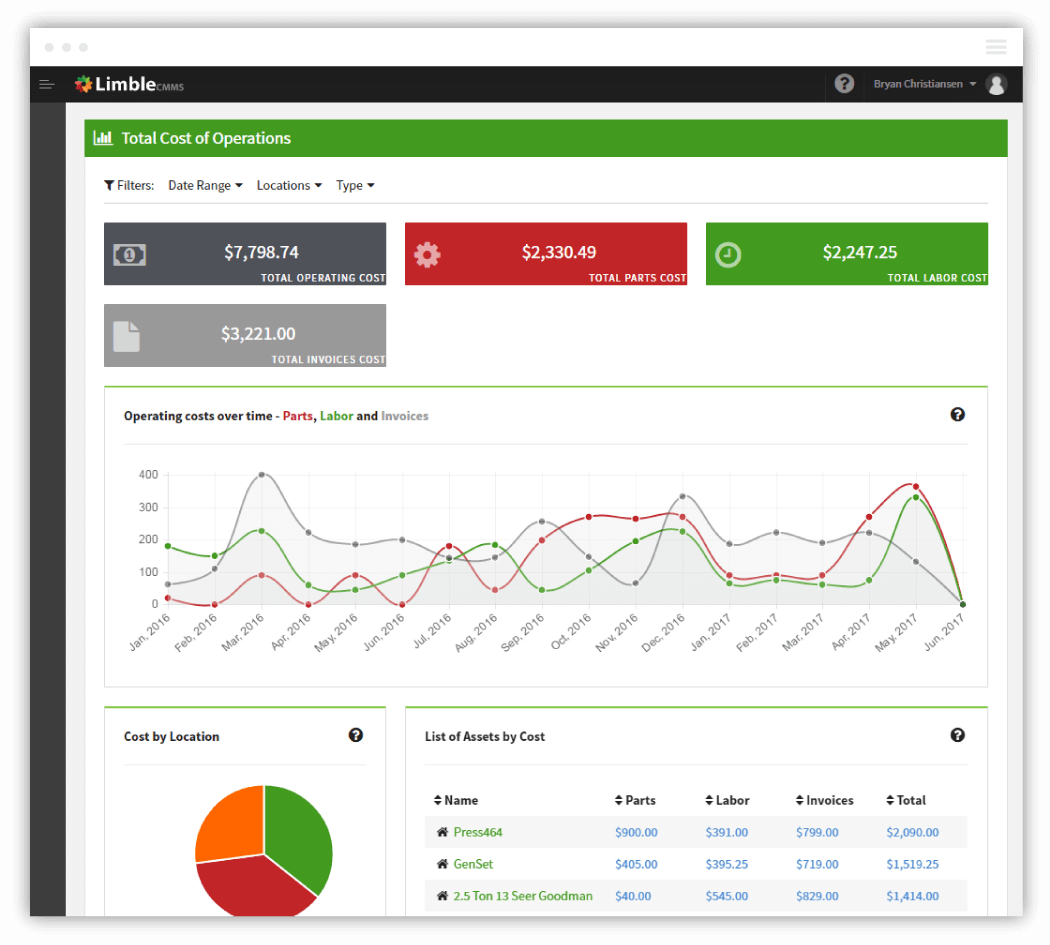

With CMMS software like Limble, breaking down your total maintenance costs by location, assets, parts, vendors, labor, and more is easy.

You can drill down into each expense and asset category to identify where you might be bleeding money. Without equipment service history, you won’t have access to such granular maintenance data.

Example: An old inspection machine breaks down frequently and costs a lot to fix. You find that 20% of its profit goes right back to maintenance costs. Installing a new inspection machine costs more upfront, but simple calculations show it will save you money over time.

3) Simplify parts inventory forecasting

It is much easier to deal with breakdowns when you have spare parts in your inventory.

With maintenance history records, you can predict when parts might break, what items may need to be replaced, and the associated tools needed for the repair. By combining this data, you can forecast your parts inventory with greater accuracy.

Example: Your data shows that your air handlers break down more often in the summer months, so you should stock up on spare AC parts at the end of spring.

4) Pass compliance audits

Regulation compliance entails understanding regulations and ensuring your practices meet them. This could refer to safety, asset disposal, and environmental protection compliance.

Maintenance history reports can provide a digital trail of maintenance that you can use to prove your compliance to external auditors. Here’s how one of our clients from the pharmaceutical industry used Limble to simplify their audit process:

Example: You will have a paper trail of when fire extinguishers were inspected, which you can use for OSHA and safety compliance. When auditors arrive, all your data is clearly and easily accessed in your maintenance history records.

5) Automate recurring maintenance activities

Every day, your maintenance team takes care of dozens of different maintenance tasks.

The data in your maintenance history records can help you automate the scheduling of recurring tasks. If you’re using a CMMS software like Limble, you can arrange work orders, create a queue, and automatically share the list with your service techs.

Limble also lets you create an annual calendar with planned maintenance tasks for each day. These assignments can feature a ton of data, like the assigned service tech, the exact time to do the maintenance, the equipment location, and notes left after past repairs and PMs.

Example: Add oil changes, lubrication, and part swaps to your calendar on your blow molding machine with automation. Let the software schedule recurring tasks for that asset, based on when the tasks were completed last.

6) Improve maintenance planning and scheduling

Planning ahead is a good way to dodge unnecessary costs, avoid headaches, and save time on maintenance tasks. You can use your maintenance history records to assume what the coming 12 months will look like, and use that to set up your preventive maintenance calendar.

By getting ahead of repairs and ensuring that a thorough and accurate maintenance schedule guides your work, you can reduce costly reactive maintenance.

Example: Maintenance history shows that your metrology tool has required calibration about 4 times a year. You can use that information to allocate tools, parts, and manpower ahead of time, avoiding painful surprises and conflicts with your maintenance schedule.

7) Predict when you’ll need specialty teams

From time to time, you’ll need to call in a contractor to handle work that requires specialized skills and tools.

Scheduling emergency repair with specialty teams can be very stressful. They always come later than you’re hoping, and they are always more expensive than they have the right to be. Using maintenance records to proactively handle work on such assets is never a bad idea.

You can look back 5 years into the history of maintenance for that asset.. If needed, schedule time with the specialist later this year to go through the machine and service it.

Example: If your history shows that you typically call in a pneumatics expert to calibrate your sensitive lab equipment at least once per year, you can proactively schedule their time 6 months ahead.

8) Speed up troubleshooting and the repair process

Some technicians have a great memory and can easily recall how they solved various issues on specific assets in the past. But, since we know that isn’t everyone, it is poor practice to rely on it.

This is where maintenance history records come in. When technicians log the actions they take to troubleshoot or resolve unusual issues, it is available in the asset history for the next technician when a similar problem arises.

If you have an asset with recurring issues, or a maintenance team big enough that there may be a different tech assigned to the issue next time, accessing these notes can significantly speed up future troubleshooting and repair processes.

Example: In a work order from two years ago, a service tech wrote that you should replace the springs before the bearings, otherwise the machine will break again. This note appears as your tech goes to fix the machine, helping them do it correctly, saving time during the troubleshooting process.

9) Optimize resources by lining up maintenance tasks

Another benefit of predicting maintenance tasks is that you can line them up to optimize manpower and hours spent.

Maintenance history records will tell you what type of personnel is needed, and how frequently the work occurs. Bundling the tasks will enable you to complete them in one go, saving internal resources and minimizing production downtime.

Example: Have your equipment lubrication team look at all of your machines in the same week so they don’t have to stop your production multiple times over the course of the year.

10) Ensure accountability

Maintenance operations are a team effort. It is something that everyone is equally accountable for. Having detailed maintenance history records is key to enforcing accountability.

Every service task will have a technician (or a team) associated with it in the record. Having the visibility to easily see the work completed by specific team members can help you:

- Identify the need for additional training or instruction when there are consistent errors by a team or individual.

- Uncover patterns of high performance and allows for recognition of strong team members.

- Provide a high-level view of team member workload, ensuring you are using all resources wisely.

- As a useful decision-making tool for workforce planning and management.

Example: The tech who does lab equipment calibration often miscalibrates, which leads to poor yield rates for your product. You can use the maintenance history records to find the pattern, and then further train the lab maintenance specialist.

11) Improve equipment reliability

Organizations that are stuck in a reactive mode often do not realize how useful accurate, real-time maintenance records can be. For instance:

- During FMEA and FMECA, historical records can be used to identify failure modes and estimate the negative effects of specific failures.

- During the RCA process, maintenance engineers can use notes left by technicians performing the repairs and use them as clues to identify root causes for various equipment failures.

- Maintenance service records are one of the inputs used to train predictive and prescriptive algorithms which predict equipment failures. The more detailed and accurate those inputs are, the less time you will need to train them.

Example: The RCA process might find that when machines are under-torqued, there is too much slop within the machine and the product suddenly falls out of spec. By correcting the torque and adding an inspection step to the preventative maintenance checklist, your machine’s reliability is improved. The whole process was sped up by having detailed maintenance records, allowing engineers to look into the data and draw different hypotheses and conclusions.

Keep your maintenance history up-to-date

Having robust maintenance history records will provide invaluable insight into your maintenance department. You’ll learn how effective your team is, where you’re falling short, and how to predict and prevent both equipment and people-related problems.

There is only one caveat. Your maintenance history records have to be accurate and up to date. Otherwise, the data is useless.

Organizations that use cloud-based CMMS solutions do not have to worry about that — the software automates most of the data collection process.

If you’re in the market for a solution to simplify maintenance management, try Limble CMMS. Start with a 30-day free trial or schedule a personalized product demo.