Performing maintenance and repair can’t always be executed directly at the location of the problematic asset. In those cases, a maintenance shop is the central area where such maintenance activities are managed and carried out, housing all the resources needed.

Every industry has its own maintenance requirements. Most of us are familiar with facilities maintenance, as office buildings, colleges, aged care homes, and sports clubs all need regular servicing and repair.

Maintenance shops and personnel support all services and products we consume daily. Aviation, manufacturing, heavy equipment, IT equipment, furniture, housing, and roads; if you can name a product or service, people and premises will be required to support their continued availability and productive use.

Maintenance shop layout and types

The term workshop or maintenance shop is generic, with workshop design, layouts, and contents differing due to the specific industry they relate to and their geographical or regulatory location.

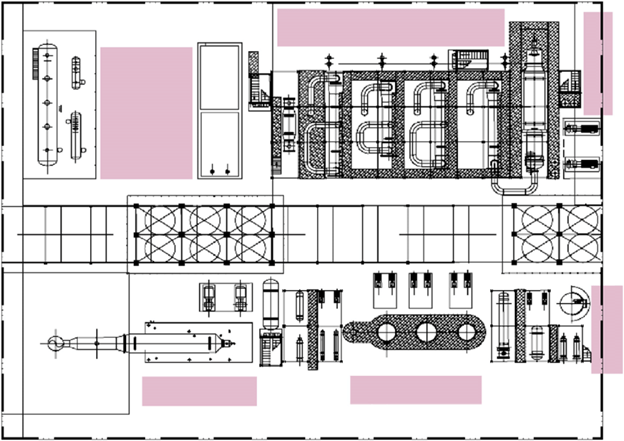

Maintenance workshop design. Source: Industry Maintenance Engineering Inc.

Maintenance shops include working spaces with workstations or benches, vehicle access and parking requirements, IT systems and software, inventory storage, tool stores, receipt and dispatch areas, clean rooms, disposal areas, and rooms or offices supporting the employees.

A key differentiator to facility location and layout is whether the maintenance shop is:

- used to service a business’s internal maintenance needs

- set up as a standalone maintenance organization providing support to multiple diverse businesses

The former is more likely to have the shop located on their premises, with tooling and equipment customized to their business needs. The latter will be located in a catchment area for multiple clients, resourced and laid out to provide a more broad set of maintenance activities.

Maintenance shop organization

There is no one-size-fits-all solution to setting up a maintenance shop. It depends on so many unique factors. Nevertheless, we can outline some general steps you can follow.

Step #1: Clarifying the purpose of the maintenance shop

Everyone should understand what the purpose of the maintenance shop is. Yes, it exists to ensure an asset’s optimal performance and reliability. Yet, maintenance does not exist in isolation – asset performance, reliability, and maintenance spend are a part of a larger business strategy.

Poor maintenance strategy and performance can destroy asset value. Clarity on maintenance needs and expectations is necessary to ensure all stakeholders are working towards the same goals.

Step #2: Planning and consultation

This step is the most important stage in developing a maintenance shop. Understanding diverse needs is crucial to implementing a solution that works for all participants. Ask and answer the following questions:

- Will maintenance be 24/7, or will it be during business hours only?

- What will be maintained, and to what level?

- Is business growth considered in shop design?

- What regulatory requirements must such a facility meet?

- How many people will work in the maintenance shop?

Setting up a maintenance shop and outfitting it correctly is not a small undertaking. The engineers and maintenance technicians will have opinions you should consider; however, so will production workers, clients, office employees, local councils, and neighbors.

Failing to identify possible operational constraints in the planning stage will require costly rectification once built.

Step #3: Developing efficient maintenance shop layout and workflows

Regardless of your industry, consider the optimal layout for the workflow in your shop.

Maintenance and repair space planning and layout. Source: Researchgate.net

For example, when designing a kitchen for our home, we minimize the triangle between bench, fridge, and sink to maximize efficiency.

Workshops are no different. If your shop is receiving items for repair, think of the way your system will work:

- If an item arrives at the workshop for repair, it must be formally received for tracking purposes. How and where is that done, and by whom?

- Does it need to go to a wash bay for cleaning? Is it placed into a quarantine store for unserviceable equipment until a technician is available?

- Will the repair involve movement through sequential workstations, or will it remain with one work desk or department?

- Will material handling be required? Will large aisles or doors be needed for such equipment?

- During repair, particularly those spanning several days, where will the removed sub-components be securely stored?

- How will the tooling be managed and calibrated to ensure availability where needed?

- How will you manage spares? Will a secure area for inventory be required? Where will you locate that?

- How will you manage equipment that is awaiting spares to arrive? Where will it be placed?

The answers you generate from such a brainstorming session will begin to solidify your machine shop layout, size, and shape.

Even if you create a maintenance shop as a central location from where mobile technicians leave and return (if maintenance isn’t carried out on the premises), the list of questions will be different – but just as important.

Walk through multiple scenarios with your maintenance team, and you’ll be surprised at the range of factors you must consider that will impact design and layout.

Last but not least, consider how mobile maintenance software can support and streamline your workflows. Fom tracking tools, equipment, and spare parts to storing SOPs, checklists, safety guidelines, shop floor plans, and other useful documents.

Step #4: Solving environmental issues and meeting regulations

The regulatory issues are empirical. You must follow them, yet how you meet the legal requirements needs some thought.

Emergency access and egress are important, as are minimum light levels, adequate ventilation, disabled access, and the minimum space requirements for the number of workshop occupants.

On top of that, there are numerous external and internal environmental issues to consider. Noise, fumes, visual disturbances, disposal of waste fluids, and the storage of waste and goods can impact neighboring buildings, visitors, and employees.

Step #5: Controlling inventory

Whether you will hold spares or plan to order them in as required, a spares control and storage system will be required. You need to think about the following processes:

- receiving components into the organization

- controlling and separating serviceable and unserviceable parts

- storing work in progress

- tracking and pricing ordered spares to a job

- dispatching serviceable items

- …

These tasks will require rooms, cabinets, parts management software, and personnel to ensure adequate control.

Be on the right side of the inventory control. Source: Plant Engineering

Step #6: Tooling control

Tools are a costly and mission-critical component in a maintenance workshop, whether general use or specialized equipment. Procurement must purchase adequate numbers of tools to suit the planned workload, and they must be tracked, securely stored, maintained, calibrated, and readily available to technicians when required.

You can use a computerized maintenance management system (CMMS) as your asset inventory management solution. Its barcoding system, alongside well-defined procedures for taking/returning tools to the storage, will ensure all tools are accounted for. Maintenance planners will be forever grateful to have access to this data.

Step #7: Managing maintenance information

Important maintenance management decisions should be based on data, not feelings, opinions, and guesses. Maintenance information, whether in paper form or digitized, must be:

- Current

- Version controlled

- Applicable to the components maintained

- Of sufficient quality and quantity

- Readily accessible to maintenance staff

These needs will drive your IT/hardware requirements, desk and workstation needs, and software subscriptions (if you are using any kind of maintenance software, which is a must for any medium or large-sized maintenance shop).

Maintenance Inventory Tracking Template

Begin tracking your maintenance and parts inventory with this free and easy-to-use template.

Keeping your maintenance shop organized

There are three levels to consider in keeping your maintenance shop operating efficiently and delivering on business expectations: strategic, tactical, and operational.

Strategic level

Develop and publish a maintenance policy. It represents a formal statement outlining senior management’s expectations of the maintenance shop. It tells the maintenance teams how they support business outcomes and sets clear boundaries that the maintenance department must follow.

Writing such a document is not difficult, but there is a defined process to follow in developing a maintenance policy to ensure that it adds value to the organization.

Tactical level

Develop and publish standard operating procedures (SOPs). SOPs flow from the maintenance policy and provide standard methods to follow for all tasks deemed central to business success.

Let’s illustrate it with an example.

When carrying out hot work or welding in a workshop, there are certain steps that must be completed to ensure you meet regulatory, health, and safety requirements. Steps such as:

- Erection of welding screens

- Disabling localized fire sensors

- Correct setup and use of fume extraction

- Provision and siting of appropriately rated fire extinguishers

- Use of appropriate personal protective equipment

In this case, you would develop an SOP to cover all the key points you require the technician to comply with before, during, and after executing the described task.

Having SOPs is just the first step. Be sure that everyone is aware of the rules they need to follow by including them in your maintenance training and onboarding processes.

Operational level

Implement a comprehensive maintenance management system. Maintenance management is a complicated process, encompassing a wide set of asset information that requires capture, monitoring, analysis, and control.

It is time to leave papers, chalkboards, spreadsheets, and file cabinets in the past – where they belong.

Utilizing the power of large databases, fast broadband, miniaturized sensors, artificial intelligence, and machine learning, computerized maintenance management systems (CMMS) are here to make your life easier and your department more efficient.

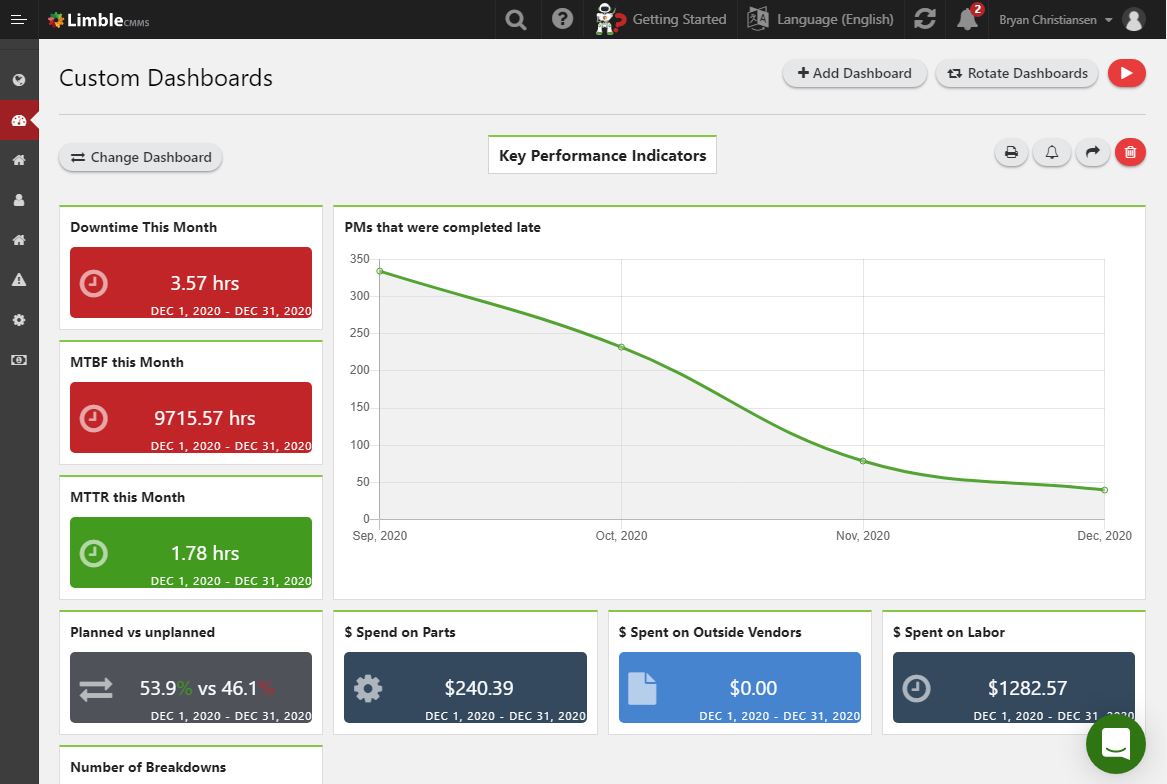

At its most basic, a CMMS is designed to track time, cycle, or calendar-based tasks requiring completion to ensure continued asset operation and reliability. However, they have many parallel capabilities. They can forecast and schedule work, predict possible failures, capture defects found during operation and maintenance activities, and propose actions to prolong equipment uptime.

Given the knowledge of future maintenance plans, a CMMS can schedule technician availability. It can also monitor and plan spares inventory, tracking spare locations, whether in stock, unserviceable, out for repair, or beyond economic repair. Tooling calibration and location may also be tracked, maintenance information maintained, and appropriate service manual pages or references provided with Work Orders and PMs.

A modern CMMS will reduce equipment downtime, improve labor efficiency, reduce inventory management costs, track expenditure, improve asset useful life, and help you stay in control of your total maintenance costs.

Limble CMMS automatically tracks your maintenance costs and other KPIs

Can you really ask for more?

Plan ahead

Setting up or organizing a maintenance shop requires the consideration of multiple issues and consultation with all stakeholders. A failure to adequately identify and scope workshop requirements will be much harder (and probably way more expensive) to solve afterwards.

Once put into operation, the ongoing control and management of the workshop are central to providing a professional, competitive, and effective maintenance service. Take your time to plan everything out, develop maintenance procedures, and implement software to streamline maintenance work.

If you wish to know more about CMMS software and how it can help organize your maintenance shop, talk to our team or schedule a free demo of Limble CMMS.