-

Uptime, all the time

Avoid emergencies and keep production running with a streamlined process for tracking and completing PM tasks.

LEARN MORE -

Fully compliant

Maintain a strong PM program with audit-ready historical data on assets and maintenance activity.

LEARN MORE -

Built for growth

Leverage Limble’s functionality, flexibility, and scalability to develop a robust, enterprise-ready preventive maintenance strategy.

LEARN MORE

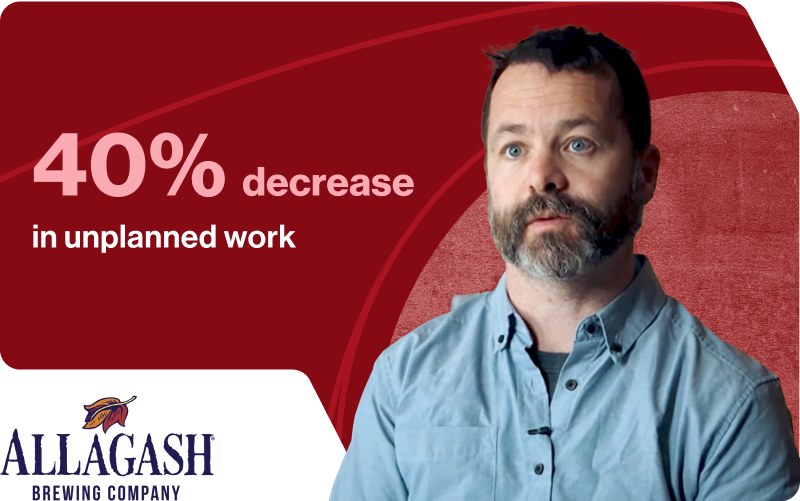

“As we put more and more data into Limble, including labor hours and the cost of parts, we're getting more and more out of it, which can generate better budgeting for the next fiscal year.”

Sean Diffley Director of Engineering VIEW CASE STUDYLimble takes preventive maintenance to the next level. See how in a personalized demo from our team.

FAQ for preventive maintenance software

What is preventive maintenance software?

Preventive maintenance software is a specialized tool, often a core module within a computerized maintenance management system (CMMS), designed to proactively schedule, track, and manage maintenance tasks before failures occur. It helps organizations shift from reactive repairs to planned upkeep, ensuring assets run reliably and extending their operational life.

Key features often include:

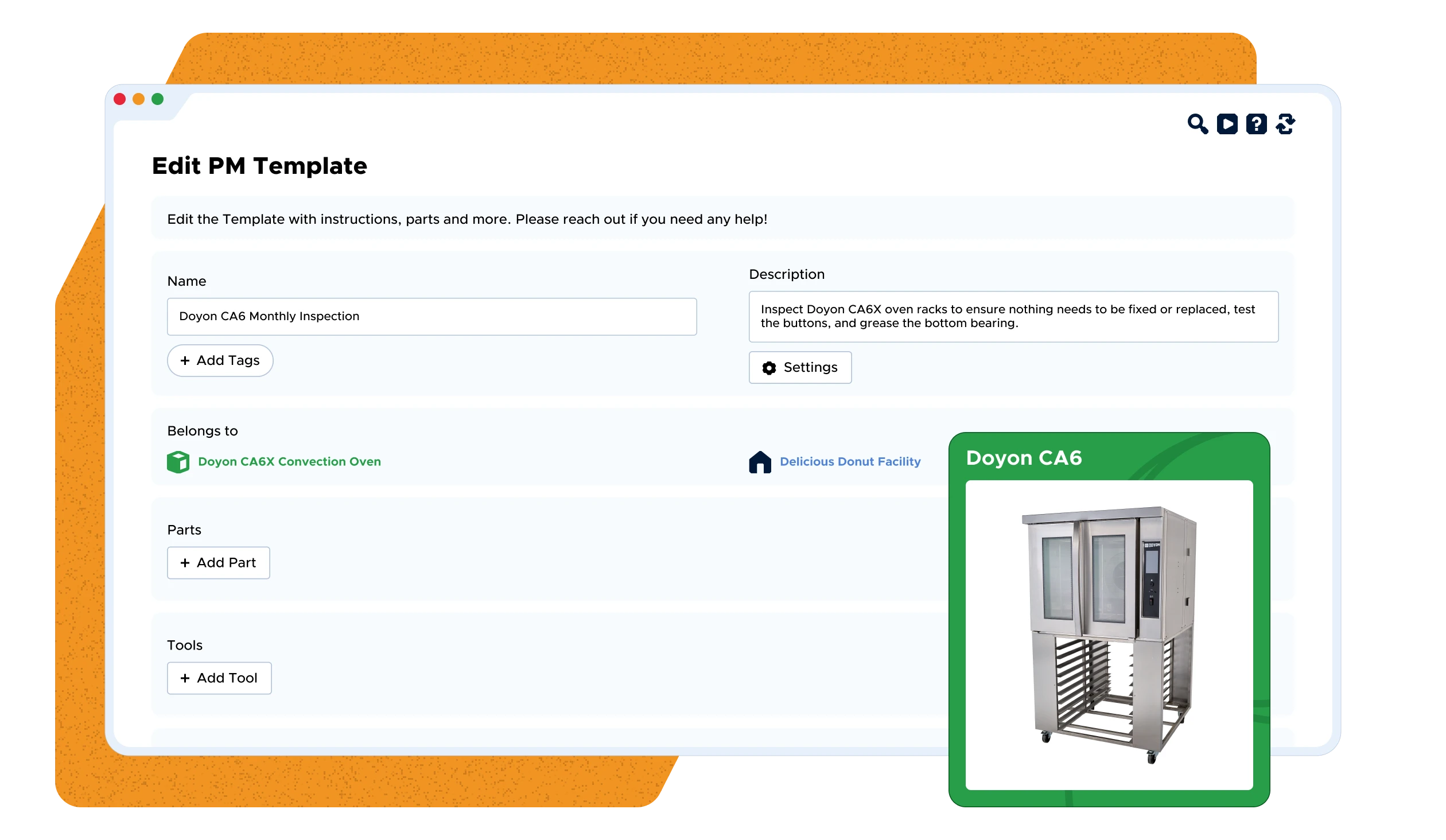

- Automated PM scheduling: Ability to create recurring maintenance schedules based on time intervals (e.g., monthly), usage meters (e.g., every 1000 hours), or condition-based triggers.

- Detailed work order management: Automatically generating PM work orders that include task checklists, safety procedures, required parts, labor estimates, and tools needed, then managing their assignment and tracking through completion.

- Centralized asset information: Maintaining a database of equipment and assets, including maintenance history, specifications, location, and related documents.

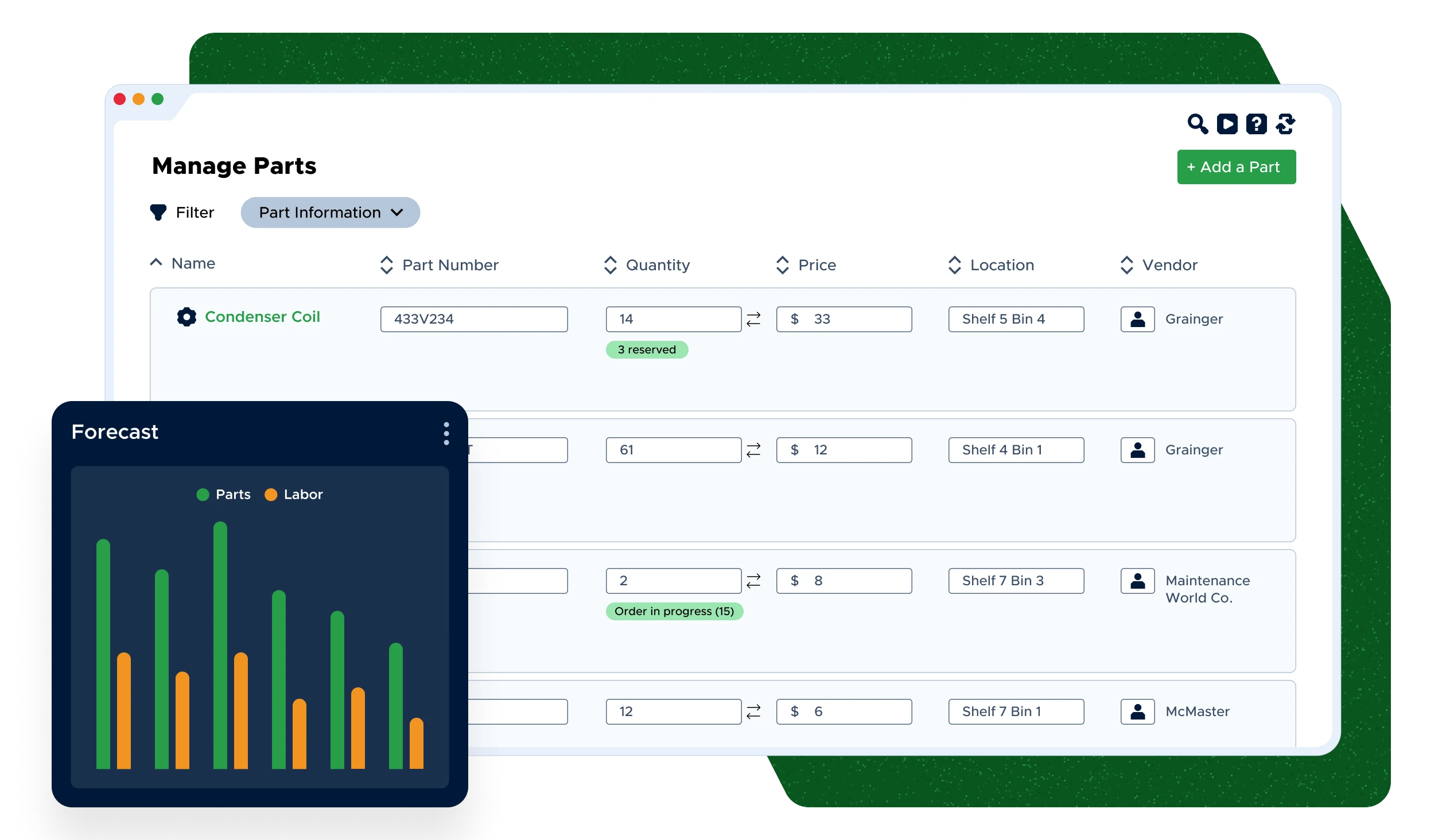

- Integration with inventory management: Capabilities to check parts availability for scheduled PM tasks, reserve necessary items, and potentially streamline the process for creating purchase orders for required parts.

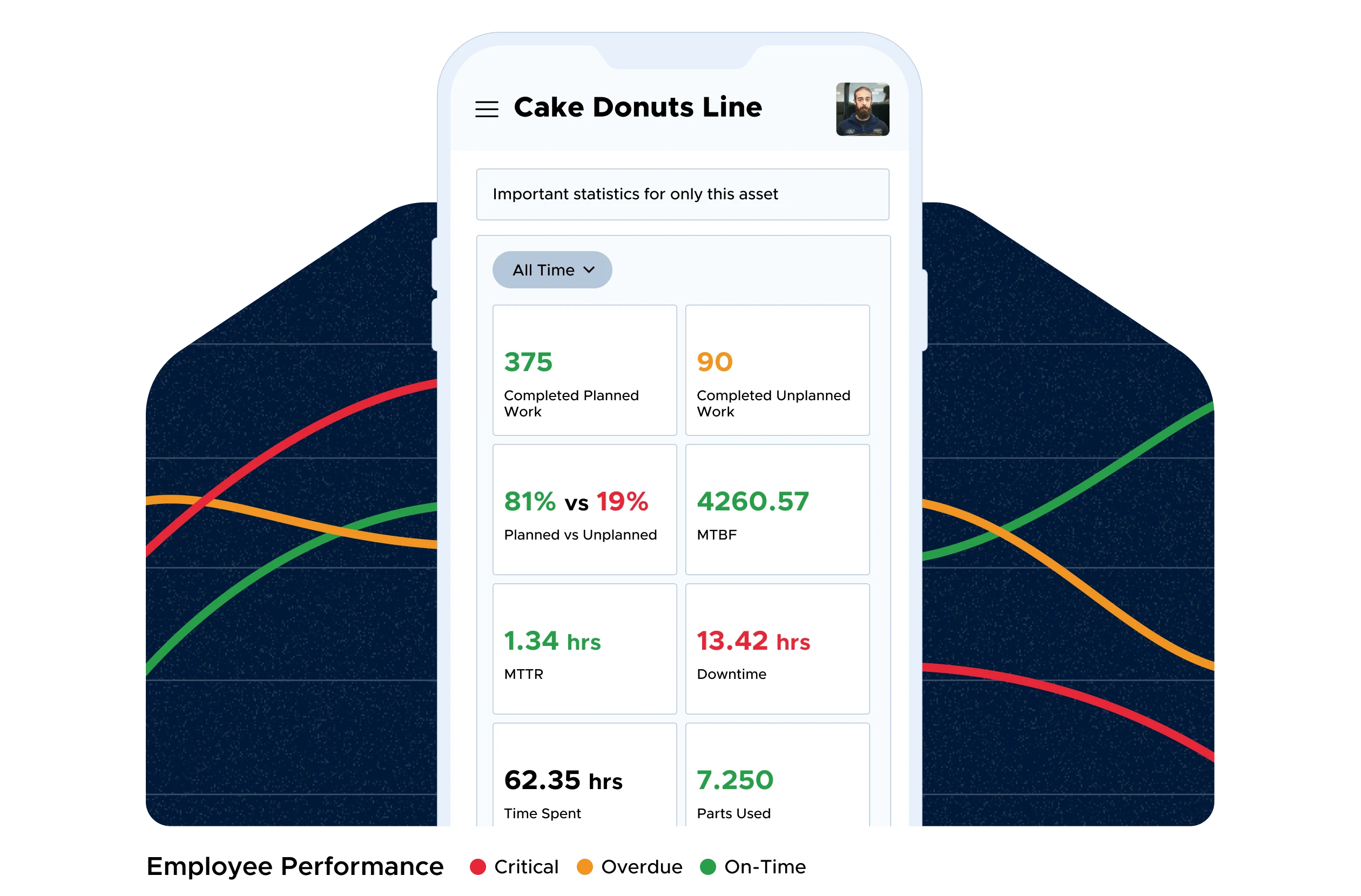

- Reporting and analytics: Tools to track PM compliance, costs, labor hours, and asset performance, enabling data-driven decisions to optimize maintenance strategies.

- Mobile accessibility: Mobile apps allow technicians to receive schedules, view task details, record work, and capture data directly in the field.

What are the benefits of using preventive maintenance software?

Using preventive maintenance software offers several key benefits:

- Reduced equipment downtime: Proactively schedule routine maintenance, generate work orders, and send notifications to prevent unexpected equipment failures and ensure smooth operations.

- Extended asset lifespan: Regular, planned maintenance helps equipment last longer and perform better throughout its lifecycle.

- Improved compliance and audits: Enforce standard operating procedures and easily access complete maintenance histories required for audits.

- Enhanced productivity: Automate the management of PM schedules, work orders (including incoming work requests), and reporting. Foundational asset tracking ensures you always know what needs maintenance and when.

Learn more about preventive maintenance management.

Who uses preventive maintenance software solutions?

Preventive maintenance software is crucial for various professionals managing maintenance operations, including:

- Facility managers: Responsible for overseeing building systems and general facility maintenance, using the software to schedule routine upkeep and ensure safety compliance.

- Operations managers: Focused on integrating planned maintenance into broader operational workflows to minimize disruptions and optimize overall productivity.

- Asset managers: Concentrated on maximizing equipment reliability and lifespan through effective PM scheduling, tracking, and analysis.

This software supports effective planned maintenance by helping schedule tasks, manage assets, and ensure safety protocols are followed.

Preventive maintenance management software is widely used in industries such as manufacturing, healthcare, education, energy & utilities, and food & beverage to streamline maintenance management and optimize resource utilization.

What is preventive maintenance scheduling?

Preventive maintenance scheduling (also known as PM scheduling) ensures tasks are planned and completed on time, preventing equipment breakdowns and maintaining a reliable equipment maintenance history.

- Automated scheduling: Maintenance work is scheduled based on time intervals or equipment usage, streamlining tracking and ensuring timely updates to maintenance history.

- Task prioritization: Critical assets are prioritized to minimize downtime and maintain detailed records of service activities.

- Real-time tracking: Alerts and logs make it easy to monitor progress, keep teams accountable, and accurately update equipment maintenance history.

Preventive maintenance software simplifies these processes, boosting asset reliability and operational efficiency.

Does Limble integrate with other software?

Limble offers seamless, pre-built CMMS integrations with popular software systems, simplifying maintenance operations for your maintenance teams. These integrations eliminate the need for developer or IT assistance, helping you get started quickly while reducing maintenance costs.

Learn more about our integrations.

Is there a mobile CMMS app?

Yes, Limble’s CMMS software offers a top-rated mobile app. Optimized for technicians in the field, our user-friendly app allows maintenance teams to execute PM tasks, use barcoding for quick asset tracking and identification, access asset histories and procedures, and manage work requests on the go.

Learn more about our mobile CMMS app.