A maintenance strategy is a comprehensive approach to managing critical assets to minimize downtime and generate cost savings while maximizing reliability and performance. Implementing the appropriate maintenance strategy or mix of strategies offers a range of additional benefits from safer worksites to organization-wide profitability.

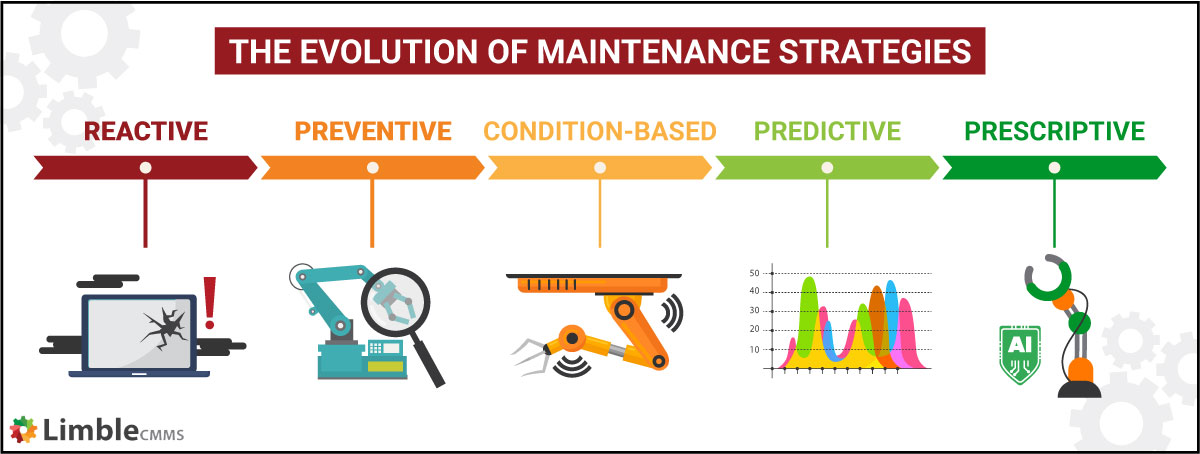

Different types of maintenance strategies have evolved as organizations across industries have embraced data analytics and emerging solutions. With real-time monitoring capabilities, organizations are largely transitioning away from purely reactive maintenance activities and adopting various different types of proactive maintenance to spot potential failures and prevent incidents from occurring.

Maintenance strategies are evolving as the function adopts new techniques and technology.

Reactive maintenance

The reactive approach to maintenance involves addressing issues after they’ve already occurred. When something breaks down, maintenance teams receive work requests or work orders and set out to repair or replace assets.

A closer look at the typical reactive maintenance workflow.

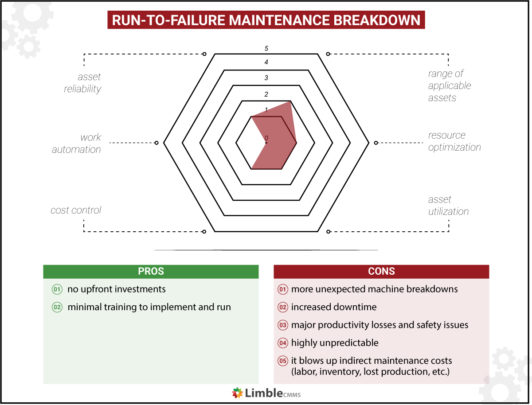

Some types of reactive maintenance are planned ahead of time. Run-to-failure maintenance, for example, is a type of breakdown maintenance in which organizations intentionally allow a piece of equipment to run until it is no longer operational. In other instances, reactive maintenance results from unexpected failures and requires a quick response to mitigate unplanned downtime.

Sometimes reactive maintenance is all you need. You probably don’t plan when you’ll replace lightbulbs, for example. For non-repairable assets or repairable assets that you don’t consider critical, reactive maintenance management may prove the most cost effective approach.

Small organizations with limited maintenance resources may opt for a reactive approach as a cost-cutting measure. That said, a reactive maintenance approach is not practical for managing essential, repairable assets in the long term. Allowing every asset to run until it breaks will invariably present a chaotic workload, leaving you struggling to manage a large backlog of deferred maintenance tasks.

An overview of the pros and cons of a run-to-failure maintenance plan.

Reactive maintenance: summary

Here’s a quick look at the basics of reactive asset management.

- Costs: No initial costs, low-cost execution

- Requirements: No significant requirements for implementation

- Best for: Non-repairable and low-priority assets that are cheap and easy to replace

You may hear the term corrective maintenance used for both scheduled maintenance tasks and unexpected, unplanned tasks resulting from incidents like equipment failures.

Preventive maintenance strategies

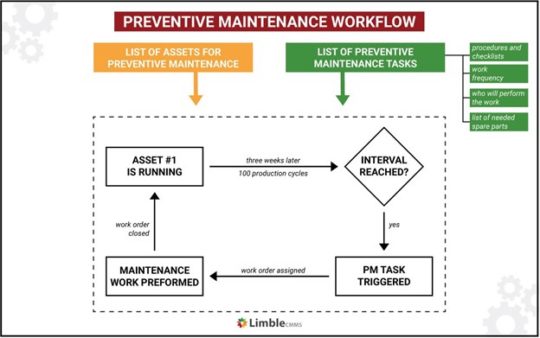

More strategic organizations adopt different types of proactive maintenance strategies. Preventive maintenance is the simplest form of planned maintenance with scheduled tasks. It may be an ideal choice for optimizing equipment performance and extending the useful lifespan for low- and medium-priority assets.

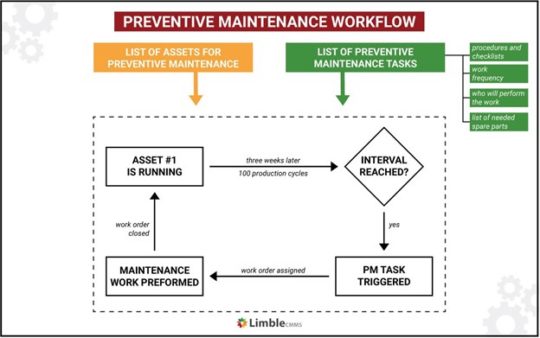

Check out the preventive maintenance workflow.

It’s certainly a popular choice. When Limble surveyed maintenance professionals, preventive maintenance proved significantly more popular than any other type of maintenance strategy. 91% of the professionals we spoke to cited preventive maintenance as their organization’s most typical approach.

Problems may arise when maintenance occurs too often or doesn’t occur frequently enough. A suboptimal preventive maintenance program could result in replacing components and assets while they’re still operational or leave you dealing with unexpected breakdowns. Organizations can keep things under control with detailed asset histories and maintenance logs. Introducing a Computerized Maintenance Management System (CMMS) simplifies this tracking and reporting to allow for data-driven decision making and program-wide improvements.

Time- and usage-based maintenance

Preventive maintenance plans are typically broken into groups depending on how maintenance activities are scheduled.

- Time-based maintenance: Maintenance activities occur based on an established calendar. For example, you might repair or replace an asset after 3 months.

- Usage-based maintenance: Maintenance activities occur after assets reach certain usage milestones. For example, you might repair or replace an asset after 500 operational hours.

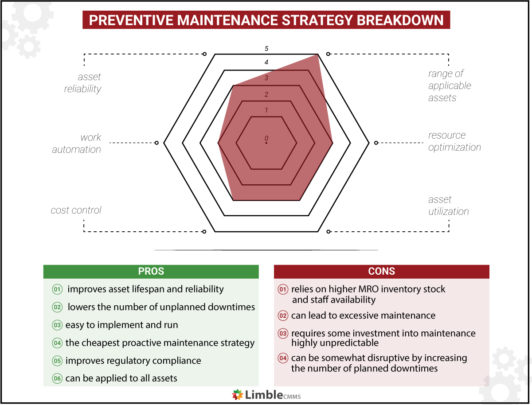

A detailed breakdown of the benefits and drawbacks of preventive maintenance programs.

Preventive maintenance: a summary

Here’s a quick overview of some key details related to preventive maintenance.

- Costs: Low-to-medium costs, the cheapest type of preventive maintenance

- Requirements: A proactive maintenance culture, systems for managing maintenance work and inventories, well-trained technicians capable of performing preventive tasks

- Best for: Low- and medium-priority assets that will cause operational problems if they fail and are expensive to repair or replace

Do you have everything it takes to manage a preventive maintenance program? Download our PM checklist to gauge your organization’s maturity and capabilities.

Condition-based maintenance (CBM)

A more advanced type of preventive maintenance, CBM involves the use of condition monitoring solutions and techniques. Vibration analysis, ultrasonic testing, infrared testing, and other techniques help to assess the current condition of assets and their components. These health metrics are used to create efficient maintenance schedules.

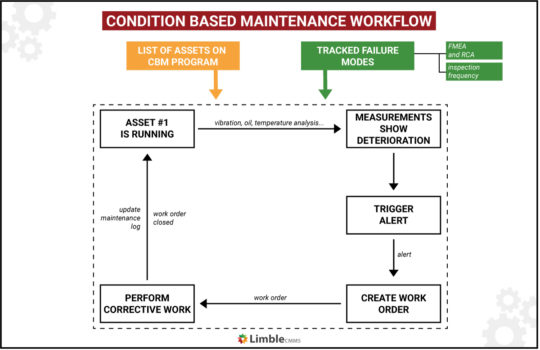

The typical workflow for condition-based monitoring and maintenance.

CBM aims to solve problems related to the way assets degrade over time. Input materials, environmental conditions, and the actions of human operators can all cause different types of assets to deteriorate at different paces.

Maintenance managers who leverage condition-based strategies do not follow a fixed schedule for repairs and replacements. They are instead guided by their monitoring data and P-F intervals. Schedules are tailored to the current condition of assets.

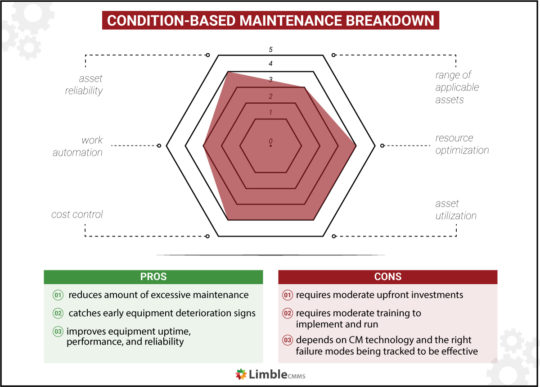

Condition-based maintenance: summary

Here’s a quick overview of key CBM details.

- Costs: Medium cost, depending on the type of condition-monitoring technology your organization has to purchase

- Requirements: Condition-monitoring equipment, platforms like a CMMS, workers who are trained to leverage condition-monitoring tools

- Best for: Any medium- or high-priority asset with failure modes that can be easily tracked with CBM equipment

An overview of condition-based maintenance’s typical pros and cons.

Predictive maintenance strategies (PdM)

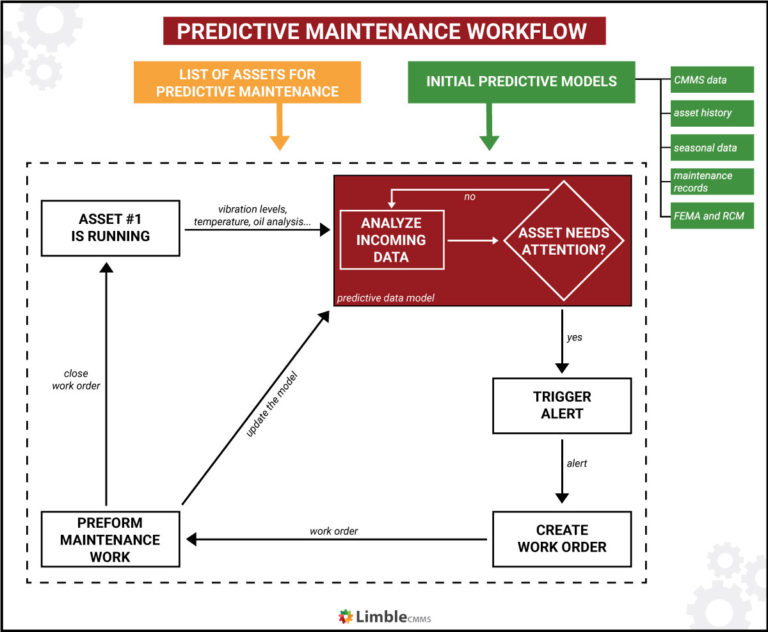

How does predictive maintenance work? Check out the typical workflow for collecting data and assigning tasks.

Predictive maintenance is a more accurate form of condition-based maintenance. These strategies involve the use of monitoring data, recommendations from OEMs, maintenance logs, and other crucial information to develop algorithms capable of predicting the likelihood of failure.

The more data your machine learning algorithms have access to, the more accurate their predictions and the better your team will be able to preemptively address failures.

Your ultimate goal when introducing predictive maintenance is to optimize the use of your maintenance department’s resources. When you have a better idea of when an asset will fail, you can plan and schedule activities well in advance. You’ll avoid both excessive maintenance and unexpected, costly equipment downtime.

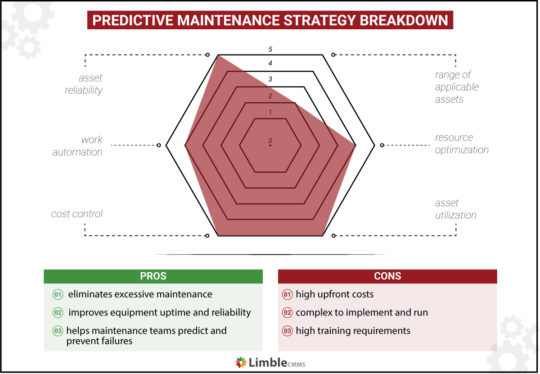

Predictive maintenance: summary

Cost: High initial costs with high potential ROI over time

Requirements: Various hardware and software solutions, condition-monitoring sensors, predictive analytics, a team with specialized training in data science and predictive modeling

Best for: Critical assets

A detailed breakdown of the benefits and drawbacks of managing a predictive maintenance program.

Prescriptive maintenance strategies (RxM)

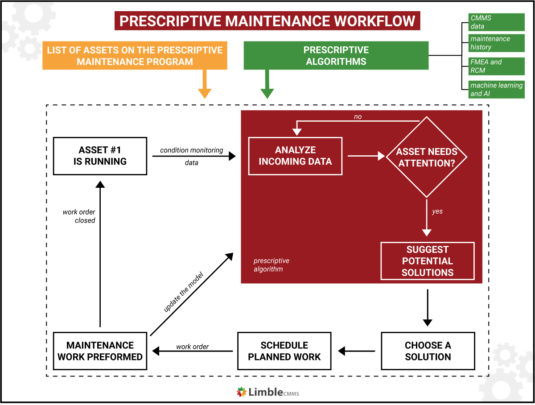

Here’s a look at the prescriptive maintenance workflow.

Prescriptive maintenance strategies are the most advanced type of proactive asset management. RxM strategies don’t stop at predicting potential equipment failures. They go one step further, offering potential solutions for the problems they identify.

For example, let’s say a piece of equipment is showing increasing bearing temperature. Predictive analytics could tell you that it will likely fail within a certain period of time. Prescriptive analytics, on the other, might advise you to slow the equipment down and double its life cycle. With more time between failures, you’ll be able to service the equipment within your scheduled maintenance window and meet your production requirements.

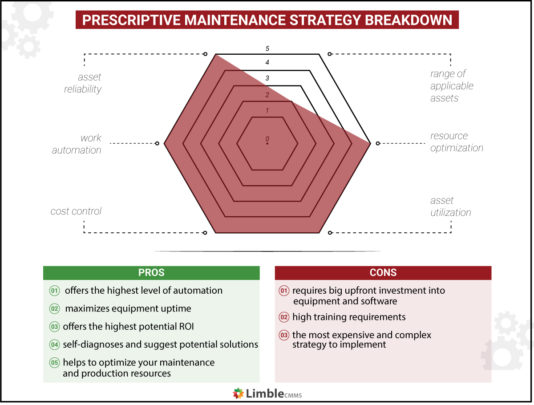

Prescriptive maintenance: summary

Here are the important details on prescriptive maintenance at a glance.

Cost: Very high upfront costs with the highest potential ROI over time

Requirements: Same as the requirements for predictive maintenance with some added complexity

Best for: Critical assets and highly automated systems with lots of condition and performance data

Check out an overview of prescriptive maintenance.

Reliability-centered maintenance (RCM)

What’s the right maintenance strategy for this asset?

A better question would be, how can we best address this asset’s specific failure modes?

Reliability-centered maintenance could give you the answers. RCM is a structured maintenance process that helps identify which particular maintenance methods will work best for each of your assets. These programs aim to improve the reliability and functionality of critical assets in the most efficient and cost-effective manner possible.

RCM analysis involves identifying functional failures, root causes, and the severity of their downstream effects. Then, this framework helps you select the most appropriate prevention methods. When you know how a particular failure will affect you, it’s much easier to devote the correct resources to addressing it.

Keep in mind that RCM is complex. If your organization is purely reactive or your maintenance logs are a mess, you may not be ready to implement RCM. Start with a simpler preventive program and start working your way up.

Risk-based maintenance (RbM)

Risk-based maintenance is another process to help you determine the most cost-effective and efficient way to use your maintenance resources. It helps you divert attention away from low-priority assets to focus on your critical equipment. This is especially helpful when you’re working with a limited budget.

You can determine the criticality of an asset using a risk matrix. Every asset is assigned a Probability of Failure (PoF) and a Consequence of Failure (CoF) factor. You use these to map each asset on the matrix. Like RCM, risk-based maintenance relies on relevant performance and health data.

Choosing the right maintenance strategy

There’s no one-size-fits-all strategy for managing your maintenance program. The best programs typically involve a mix of different approaches, tailored to the health and criticality of assets. At a high level, picking the appropriate strategy requires a thorough understanding of:

- Your assets (their health, failure modes, and maintenance requirements)

- Your capabilities (budgets, skills, access to tools and technology)

- Maintenance strategies (how they work, their pros and cons, the costs and requirements)

Let’s take a closer look at the criteria that should help you determine the right mix of maintenance strategies for maximizing the lifetime value of your assets.

- Budget: The size of your maintenance budget will go a long way in determining the strategies you can successfully deploy.

- Existing assets: The most cost-effective approach to maintenance will vary based on the specific asset. For low-cost equipment, a reactive approach may be the best way to balance availability with maintenance costs. If you primarily use highly sophisticated equipment, you’ll want to favor a more proactive approach to maintenance work.

- Maintenance team: No amount of machine learning capabilities and tech-powered analytics will eliminate the need for a dedicated team of well-trained professionals.

- Regulatory requirements: Certain industries compel organizations to conduct maintenance and monitoring work on a regular schedule.

Steps for selecting a maintenance strategy

- Set a foundation: Do you have everything it takes to introduce an effective maintenance strategy? Assess your team’s capabilities and resources you have at your disposal. Establish a committee to set out goals for the program and offer strategic guidance.

- Conduct a criticality analysis: A risk analysis is crucial for determining the priorities that should drive you maintenance strategies.

- Assess the costs and benefits of different approaches: Now that you understand which assets need the most attention, you can start to dig into the relative costs and benefits of

- Implement your strategy: Introduce your new tools and workflows, taking care to ensure your team is well trained and ready to accept their new responsibilities.

- Monitor your performance and make adjustments over time: Your maintenance program is meant to evolve over time. Collect performance data on an ongoing basis to recognize and act on opportunities for improvement.

Need help transitioning away from reactive maintenance?

Not sure where to start? We’ve got you covered. Download our Reactive to Preventive Maintenance Transition Guide to learn all about planning the switch to preventive maintenance, avoiding common pitfalls, and realizing the full benefits of your new program.

Guide to Moving from Reactive to Preventive Maintenance

Want to transition away from costly reactive maintenance but don't know where to start? This guide has everything you need to know.

Want to learn more? Check out Limble’s case studies to learn more about how maintenance and facilities management professionals have embraced more effective maintenance strategies with the help of our CMMS.

Thanks for sharing this blog. When conducting maintenance tasks, there are a few things to keep in mind. You should always make sure you have the approved manuals, tools, and parts on hand and practice thorough documentation.

I find your material very useful, I have gone through most of it. I wonder if I could use some of it in my classroom, and of course, I will mention the source.

Feel free to do so Carlos 🙂

It’s really perfect, esp. the illustrations and statistics, I’m an Asst.Prof. giving lessons on Maintenance, do you have any papers about these comparisons?

We’re glad you’ve found it helpful 🙂 We do not have specific papers to cite, this is more of a rough comparison based on our experience in the industry.

Each plant has its own conditions and specifics so we avoided giving stats that might not be applicable to the majority of readers.

In any case, good luck with the lessons!

Comments are closed.