Maintainability

Everything you ever needed to know about maintainability.

What is maintainability?

Maintainability describes how quickly and easily technicians can detect defects, locate the affected equipment, and return assets to operational condition.

Maintainability is an important concept in manufacturing, software engineering, and other fields. The easier it is to perform repairs and maintenance on an asset, the higher its maintainability.

You can measure maintainability by calculating an asset’s mean time between failures (MTBF) and mean time to repair (MTTR). These KPIs track the average time your equipment spends operational and the time it takes technicians to get assets up and running after identifying problems.

Both planned and unplanned downtime affect your organization’s bottom line and production capabilities. Enforcing high maintainability standards helps to maximize equipment uptime. You and your technicians should aim to complete maintenance tasks as quickly as possible while incurring the lowest possible maintenance costs.

Maintainability and its relation with reliability and maintenance

Maintainability and its relation with reliability and maintenance

Reliability, Availability, and Maintainability

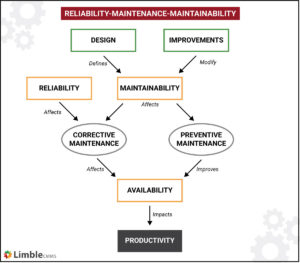

Maintainability is closely related to the concepts of reliability and availability. Together, all three ensure professionals understand the performance of their equipment and continually maintain an effective asset management program.

The acronym RAM combines the three terms. RAM analysis provides insights for developing best practices to minimize downtime and lifecycle costs.

- Reliability describes the probability of an asset performing its intended function under typical operating conditions for a set amount of time. Tracking reliability defines the asset’s failure frequency and determines its uptime patterns. Reliability is often measured through MTBF. An unreliable asset is one that regularly experiences unexpected failure.

- Availability represents the percentage of uptime over a specific time period. It calculates the likelihood that a piece of equipment will be operational when you need it. Reliability and maintainability both contribute to an asset or a system’s availability.

- Maintainability describes how quickly and easily your technicians can perform necessary repairs and get assets back to their normal operating conditions. An asset with low MTTR is highly maintainable. Maintainability requirements vary from asset to asset based on the criticality of the machine, the cost of repair or replacement, and the consequences of downtime.

Any facility that relies on physical assets or software systems can track and report on these metrics to optimize operational performance.

Six best practices for asset, system, and software maintainability enhancement

Throughout the equipment lifecycle, a number of best practices can help enable preventive maintenance to keep critical assets and systems highly maintainable.

1) Standardization

Minimizing variety among parts and components helps simplify inventory management, tooling, and training. Standardization ensures compatibility between the USB ports on your computer and various types of devices. In an industrial setting, the benefits of standardization include minimizing the types and sizes of bolts and fasteners used in an asset.

2) Modularization

Modularization involves constructing complicated machines or systems from smaller building blocks (or modules). Each block is maintained independently. This improves maintainability in the following ways:

- Facilitating easy disassembly and reassembly of machines. This improves accessibility to the parts requiring maintenance or replacement.

- It is often more cost effective to replace sub-assemblies than repair a damaged asset. You can potentially repair the damaged modules later and retain them as spare parts. These practices can significantly decrease MTTR for any of your assets.

- Modularization enables system-level upgrades. It may be more cost effective to upgrade one or more sub-assembly rather than changing out a full asset.

A simple blender presents an example of modularity in action. You can easily separate the base from the various jars and blades. This can facilitate simple repairs or enable you to modify the machine’s capabilities to suit different recipes.

In power industries, turbine rotors are designed so that turbine blades get assembled over turbine wheels. These are then fitted onto the rotor shaft. Modular construction allows for easy replacement of damaged blades and upgrades to more efficient blade designs.

3) Interchangeability

Interchangeability is an optimization strategy for maintenance activities that involves using commonly available generic components rather than custom-fit parts. This simplifies repairs and replacements. The end user can rely on alternate spares from the market when original spares aren’t available.

A common example is the use of standard bearing sizes in pumps and other machinery.

4) Malfunction annunciation

When equipment or software fails to perform its intended function, malfunction annunciation provides a real-time alert to operators. This enables a quick response to minimize excess downtime.

For example, the temperature gauge in a car informs the driver about early signs of an overheating engine. This allows them to take the appropriate corrective action.

Complicated machines in heavy industries rely on elaborate monitoring systems. These systems include temperature sensors, pressure sensors, vibration monitoring devices, and other condition-monitoring equipment used in CBM and predictive maintenance. Any deviation from the established limits raises alarms to the operator. Then, the operator can take action to notify relevant personnel. From there, managers can ensure maintenance is scheduled to optimize resource allocation and minimize the impact of downtime.

5) Fault isolation

Whenever an asset breaks down or malfunctions, you should take time to diagnose the root cause of the problem. When root causes aren’t obvious, the diagnostic process requires a significant investment. You can avoid wasting time and money by incorporating design features that limit opportunities for human error, make the sources of issues obvious as possible, and simplify corrective maintenance.

For example, most electronic home appliances show an error code for common issues and failure modes. Error code E1 might tell you that the discharge pipe in your washing machine is blocked. You can resolve the issue by readjusting the pipe and removing the source of the blockage. An ‘unknown error’ code, on the other hand, would have necessitated bringing out a technician to troubleshoot the issue.

In a manufacturing setting, a ‘high-vibration’ signal can tell an operator that something is wrong with the machine. Then, a more detailed analysis of the signal can allow a trained diagnostic engineer to identify the component or asset requiring maintenance. Without such a monitoring system, you’d be forced to carry out a costly process of trial and error.

6) Identification and tagging

Keeping assets, equipment, assemblies, and sub-assemblies clearly labeled facilitates communication and simplifies record keeping. Asset operators should assign unique and meaningful tags wherever relevant.

Asset operators achieve this by assigning unique and meaningful tags to assets and components. For example, you might designate heat exchangers with the letter H followed by a three-digit code.

Assigning unique part numbers ensures that the correct parts are arranged for maintenance, avoiding confusion and unnecessary downtime. An equipment-tagging system also simplifies the processes of storing maintenance instructions and historical records.

Want to see Limble in action? Get started for free today!

More best practices methods for maintenance management

Small improvements across the organization can simplify maintenance work on complex assets and improve maintainability:

- Upskill maintenance workers and operators: The maintenance department should take care to provide adequate training to all operators and technicians. This is especially important when new requirements or pieces of equipment are introduced.

- Standardize routine work: Alongside training programs, standard operating procedures (SOPs) help to drive down operating and maintenance costs while increasing productivity and reduce human error.

- Focus on proactive maintenance: More proactive maintenance leads to fewer costly breakdowns and maximizes asset productivity.

- Implement a CMMS: Computerized maintenance management systems centralize essential documents like preventive maintenance checklists, SOPs, and more. With dashboards for reporting on essential metrics, they simplify performance management and pave the way for continuous improvement.

Want to learn more? Download our CMMS guide to learn more about how Limble’s platform and mobile app transform maintenance management.

The Essential Guide to CMMS

Download this helpful guide to everything a CMMS has to offer.