Effective machine maintenance leads to increased equipment availability, performance, and utilization. Reliability-centered maintenance (RCM) is the gold standard for organizations seeking to optimize maintenance. However, implementing RCM requires considerable administrative and financial investment.

In case such an investment is not possible, here are eight core maintenance principles that you can implement at minimal cost to improve your machinery servicing process.

Checklist for Creating a Preventive Maintenance Plan

Following a consistent Preventive Maintenance Plan can make life easier. Use this checklist to create your own!

1) Implement a simple condition-monitoring system

Catastrophic failures aside, most equipment will show signs of deterioration long before performance drops noticeably or product quality is affected. Condition monitoring consists of observing a specific condition on a machine to identify changes that might signal an emerging fault.

Machine monitoring allows maintenance interventions to be scheduled to prevent failure and restore equipment health.

For a critical item of machinery, consider how to best monitor its ongoing health. What will be the one or maybe two conditions to monitor that will provide an early warning of distress?

Common condition monitoring techniques focus on the following characteristics:

- Oil analysis: Use a lab to regularly carry out spectrometric analysis on oil for fluid properties, contamination, and wear debris.

- Vibration analysis: Test for bearing failure, bent shafts, worn teeth, misalignment, and looseness.

- Thermography: Identifies bearing overheating, mismatched belts, loose connections, and motor brush issues.

- Pressure/Flow: Identify pump wear, clogged filters, and valve failure.

Implement a set frequency – daily, weekly, or monthly machine monitoring. Track and graph the results to identify trends.

This approach forms the basis of a condition-based maintenance program.

2) Introduce equipment logs and training for operators

Your machine operators are the first line of defense against machine deterioration. They use the equipment every day and are tuned into the look and sound of correctly operating equipment.

Still, we can’t run away from the fact that operator errors are one of the more common causes of equipment failure. It is paramount to ensure they all use the equipment in the proper manner.

Develop a standard operating procedure that all operators must follow to ensure safe and efficient machine operation, then train them to use it. Furthermore, teach them how to spot common faults, and use them to carry out minor daily tasks such as cleaning and lubrication. In other words, consider implementing autonomous maintenance.

To make their life easier, introduce equipment logs that operators can use to record their concerns, observations, or faults. Have your maintenance personnel check the logs at least daily. Require all open items to be closed off in one of three ways:

- The concern is not an issue and can be signed off.

- The technician can fix it immediately.

- The issue is raised as a planned maintenance (PM) task for the next maintenance period but is signed off in the equipment log showing the PM task number for traceability.

3) Develop planned maintenance task kits

When carrying out regular planned maintenance on equipment, these recurring tasks will often require the same components and consumables.

Rather than leave the maintenance technician to assemble all the items needed before each PM task, develop a set of pre-packaged kits and give each a dedicated part number. Record the kit part number on the planned maintenance task to improve traceability and minimize potential confusion.

Preventive maintenance kit for FS 8000H OEM Air-Compressor. Source: Alibaba.com

When a regular maintenance task is scheduled, a store person can draw the kit associated with each planned task from stock. On scheduled maintenance day, the technicians will receive a pallet of all the kits relevant to the tasks planned for that maintenance shut.

Kitting ensures all required resources are available before the planned maintenance event. It allows technician time to be used effectively. It also supports small but important tasks like lubrication or gasket replacement that might otherwise be omitted if a technician had to leave the shop floor and look for parts.

4) Track performance metrics

Assuming your maintenance program is effective, a failure to carry out planned maintenance tasks will adversely impact machine reliability over time, as well as its lifecycle. In a perfect world, we carry out preventive maintenance and get only one or two breakdowns requiring emergency attention.

However, if you’re trying to get on top of unreliable equipment, more frequent breakdowns are bound to tie up your resources.

Tracking maintenance performance is a useful gauge of whether planned maintenance tasks are being completed on time and at the required frequencies. It also shows whether maintenance backlog items are being cleared and how much equipment downtime was incurred.

Additionally, tracking failures will help identify high-frequency failures. Using that information, you can increase PM frequency or schedule additional tasks to improve reliability.

Tracking these five key measures is a good start:

- Number of PM tasks completed per month versus tasks planned

- Number of breakdowns per month

- Causes of breakdowns by equipment type or location

- Number of maintenance backlog items cleared versus added per month

- MTTR and MTBF

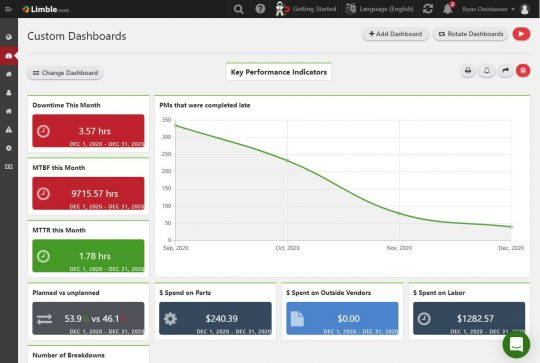

Limble can automatically track your predefined metrics

You can see whether your maintenance is improving or sliding backwards by following these maintenance metrics, allowing you to identify systematic issues that might require specific workflow adjustments.

5) Streamline machine maintenance with a modern CMMS

If you can’t capture data on your equipment performance and maintenance procedures, you’re basically flying blind, and you’ll struggle to optimize your operation. Implementing a computerized maintenance management system is far easier than it was just a few years ago, and the value you receive from gaining insight into your maintenance performance is immense.

Subscribing to a modern CMMS is a low-cost and effective way to begin capturing operational data and managing maintenance activities. Most maintenance software is cloud-based (can be accessed on a mobile device) with core features like:

- Preventive maintenance calendar and scheduling

- Spare parts inventory management

- Asset management

- Work order management

- Reporting

They can also link to other existing business solutions such as finance and human resources. As technology has advanced, a modern CMMS software allows connection to wi-fi systems to collect data from machine sensors in real-time.

6) Optimize PM tasks

Planned maintenance tasks can often be treated as set-and-forget – once written, they are rarely revisited. Carrying out an ongoing, rolling review of all planned maintenance tasks is a vital part of you maintenance strategy. It allows each task to be checked for the following:

- Continued relevance: Do you still need it? If not, delete it.

- Effectiveness: If needed, is the described task the most effective way to proceed? Does it need more or less information or steps?

- Efficiency: While the task may accomplish what you need, can you streamline it to make it more efficient?

- Accuracy: Does the task reference the correct manual references and spare parts kits?

- Planning: Is the time allowance sufficient or overestimated? And are the human resources required for the task still relevant and accurate?

- Duplication: Are there some overlapping tasks? Maybe it’s time to combine them into one.

- Lack of a task: Does your data suggest a new PM task might be appropriate, or does the review identify neglected equipment?

During the optimization, identify those tasks that could benefit from additional standardization. Streamline them by creating specific preventive maintenance checklists, and then integrate those into your maintenance plans.

Implementing a culture of continuous improvement allows for small ongoing adjustments to your maintenance program, ensuring maximum return on your maintenance dollar.

7) Create a lubrication schedule

Instead of burying lubrication into planned maintenance tasks, create a stand-alone lubrication schedule to ensure each item is lubricated when it is due.

Creating standalone, routine maintenance schedules for lubrication ensures you will:

- Search for, find, and record all lubrication points. Often a difficult task on older machines.

- Think about operating hours or cycle times. Lubrication is a dynamic task that alters depending on machine use.

- Include every oil change in the schedule and capture the results of every oil sampling.

- Identify the correct lubricant to be used, its quantity, and the procedure that must be followed.

- Perform corrective maintenance tasks if lubrication points are found blocked, broken, or obscured.

Achieving maximum asset design life depends on several variables, but a fundamental action to assist reliability is a comprehensive lubrication schedule.

8) Do soft foot analysis and shaft alignment on pumps and gearboxes

Shaft misalignment on rotating machinery contributes to increased maintenance costs and premature failure due to the following issues:

- Increased vibration

- Excessive seal and bearing wear

- Shaft or coupling failure

- Increased friction

- Increased energy consumption

- Increased lubricant leakage

- Mounting bolt failure

- Belt wear and failure

Before or during shaft alignment, you should perform soft foot analysis. Soft foot refers to one or more of the feet of the rotating equipment not making good contact with its mounting plate. Left unshimmed, mounting castings can crack during operation, leading to misalignment and excessive vibration.

Using laser alignment systems during pump or gearbox installation will ensure the rectification of soft-foot problems and correct shaft alignment. Correct alignment helps rotating equipment last as long as possible, reducing premature failure and downtime. This example illustrates how different types of machine maintenance can all contribute to the end goal of effective equipment maintenance, as well as keeping industry machines and other pieces of equipment away from unplanned downtime.

Getting machinery maintenance to the next level

Implementing a comprehensive reliability-centered maintenance (RCM) program will pay dividends in operations uptime, equipment reliability, and reduced maintenance spending.

However, if RCM is outside your financial ability, you can work according to the 80/20 principle. The idea is that 80% of your maintenance gains will come from 20% of the preventative actions you perform daily. We outlined some fundamental things that you can implement in isolation, which form the core of all effective maintenance programs.

Limble CMMS is designed to organize, automate, and streamline maintenance management. To learn how, request a demo, start a free trial, or simply send us your questions.