As business owners and maintenance managers, our daily imperatives can lead us into the trap of focusing on short-term results. Applying short-term thinking to business areas like physical asset management is a recipe for disaster.

In this article, we’ll take a step back to understand why some of our thoughts and actions regarding physical assets may cause us to overspend or underperform as a business. We’ll highlight the most common errors and discuss the right way of approaching physical asset management.

What is physical asset management?

Physical asset management is as much a way of thinking as it is a series of tactical and operational tasks. It represents a systematic way of managing physical assets with a focus on their sustained performance – emphasizing performance over their lifetime rather than a daily, monthly, or annual cost and uptime.

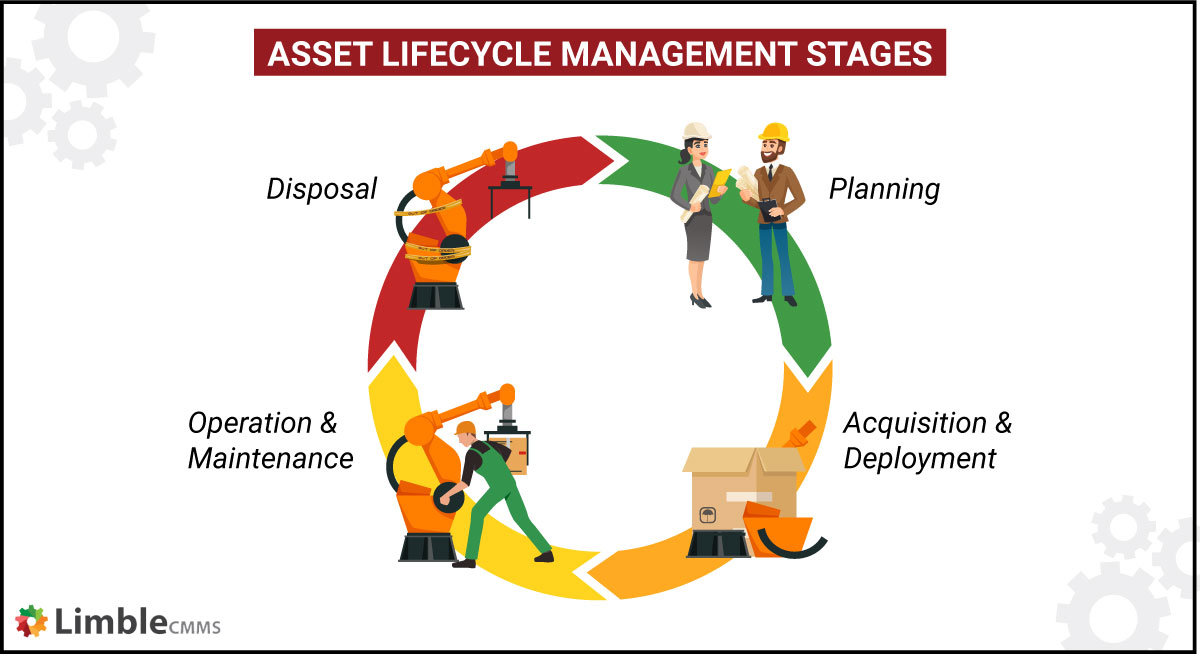

In other words, physical asset management gives us a framework to make smart decisions throughout the life-cycle of the asset, from planning to disposal.

That results in us achieving the lowest total cost of ownership, allows us to develop long-term funding strategies, minimizes whole-of-life capital spending while optimizing asset efficiency and return-on-investment (ROI).

Checklist for Creating a Preventive Maintenance Plan

Following a consistent Preventive Maintenance Plan can make life easier. Use this checklist to create your own!

6 common physical asset management mistakes

In operations management, our focus is often on the immediate – those imperatives and concerns impacting us today or this week. Yet, in solving those problems, we can fall into the trap of eroding business value over the long term.

The following are six common physical asset management mistakes – accompanied with practical solutions.

Mistake #1: Confusing maintenance with an asset management system

Our thinking about asset management often begins when a piece of equipment is delivered and installed, and it ends when the asset is replaced. At best, we feel that carrying out the original equipment manufacturers (OEMs) prescribed maintenance is extracting maximum value, while at worst, we consider ourselves clever if we can boost profitability by shaving some cost off the maintenance budget, scrimping on required tasks.

Solution: Understand maintenance as a subset of asset management

When we broaden our knowledge of an asset management system, we understand the considerable analysis and consideration that must go into equipment selection. Before equipment purchase, we’ve:

- understood the asset lifecycle

- identified the expected replacement costs

- developed target levels of service

- determined business risk accruing from the selection

- assessed the asset’s likely performance and failure modes

- analyzed equipment maintainability

- determined a funding strategy

After all this analysis and data collection, we finally consider the tactical and operational application of maintenance.

Maintenance is a small but integral part of physical asset management. Correctly developed and implemented, it ensures the planned service levels, business efficiency, and total cost of ownership meet the budgeted targets set upon asset acquisition.

Mistake #2: Using insufficient data for maintenance scheduling

Once an asset is installed, it’s not uncommon to see the application of generic maintenance management strategies. Worse still is a set-and-forget approach to maintenance that, apart from minor changes and additions to planned maintenance tasks, remains static over the asset’s life.

Solution: Implement digital information systems

Much of the asset assessment done during procurement – before acquisition – will depend on manufacturer-supplied data and the in-service experience of other operators. Excluding other information, this is fine for the initial purchase. However, once the asset is installed and begins operating, it’s important to begin baselining actual operation against its theoretical performance specifications.

A critical part of the asset acquisition study should highlight the information system requirements, including hardware, software (like CMMS and predictive analytics), sensors, and necessary data to monitor and record in-service asset performance.

Used as a live system, this data allows appropriate modifications to the operation, maintenance, or even the physical asset itself to ensure that service levels and performance meet preplanned targets and achieve full economic life, optimizing the asset lifecycle and its sustainability.

The use of a modern computerized maintenance management system (CMMS) is key to an effective asset management strategy.

Mistake #3: Not having staff on board with the maintenance vision

Problems arise, and efficiencies are lost when machine operators and maintainers blindly follow standard operating procedures and maintenance checklists with no understanding of the wider ramifications of their maintenance activities within the management process.

Or worse yet, people begin short-cutting methods, apply ‘tick-and-flick’ or ‘pencil-whipping’ maintenance, signing-off on the tasks without acquitting them – a depreciation of their own workflows, as they believe those tasks are unimportant and a waste of time.

Solution: All employees should become asset managers

All the plans, targets, and monitoring will be for nothing if the employees don’t fully understand and value their contribution to the correct and optimal functioning of an asset and the asset lifecycle in general.

This is especially relevant for machine operators. They have a key role in ensuring operating methods are followed. As the first people to sense a change in movement, sound, or output of physical assets they work with, they are essentially stakeholders in the process, and it is important that they feel their contribution is valued and respected and that it is safe to speak up. Nurturing such an environment is at the core of autonomous maintenance.

Maintainers who fudge hours spent on a task, omit tiresome or complex tasks, or feel that because they did a task last week, it doesn’t need to be done this week, guarantee that the asset will not achieve optimal operation.

Winning the hearts and minds of technicians can be done by including them in the planning processes, increasing individual accountability, and trusting them with broader information that normally might not be shared. When people understand the big picture behind the enterprise asset management, and have input into operational processes, it is much easier to develop ownership of the work they do and assets they maintain.

Having a strong maintenance policy document is another great way to let people know what their approach to maintenance should be and why that matters.

Mistake #4: Buying on price instead of maintainability and operability

While it should barely need saying, the value of an asset is not defined by its purchase price. Too often businesses confine their acquisition decisions to capital expenditure, without fully understanding the operational expenditure ramifications of their decisions.

Such errors compound when the purchase decision is not made by those responsible for meeting operations targets or maintenance budgets. It’s too easy to hide the errors of a bad purchase in day-to-day operating costs.

Solution: Analyze asset cost over its lifetime

A major component of the total life cost of an asset lies in spares and maintenance. If a piece of equipment is cheap to acquire yet suffers from poor maintainability, high-cost spares and consumables, extended maintenance downtime, or highly expensive test equipment and technical support, the savings from the original purchase will rapidly evaporate.

In the pre-purchase analysis, operators and maintenance representatives must take part in an in-depth review of the likely maintenance costs involved in the whole-of-life support for the equipment, including training, tooling, decommissioning, and asset disposal costs.

Management may then make an informed decision, having identified the total ownership cost of each asset that is currently under consideration.

The Essential Guide to CMMS

The Essential Guide to CMMS

Mistake #5: Outsourcing maintenance based solely on contractual cost

In a similar scenario to the previous mistake, we too often consider the value of an outsourced maintenance strategy on the spend implicit in the contract. Looking to minimize operational spending and to increase our bottom line, we negotiate the contractors down to the point of pain.

Satisfied that we’ve done our job, we seldom realize that the entire focus of the outsourcing discussion is facing the wrong direction and potentially eroding value through a zero-sum approach.

Solution: Emphasize asset continuity and shared asset responsibility

Maintenance contracts must start from the basis of value accretion. Commissioning a contractor begins by selecting one that understands the total cost of ownership concept, supports a culture of continuous improvement, and is prepared to partner with you, sharing responsibility for the asset performance.

Agree on clear service level expectations, improvement goals, and auditable, reasonable, key performance indicators (KPI). From those KPIs, the contractor should be prepared to have some upside revenue at risk for non-achievement while being rewarded for outstanding performance that exceeds targets by an agreed level.

By not seeing outsourced maintenance as a cost but as an opportunity for a long-term partnership with a sophisticated maintenance provider, together, you can deliver the required service levels while minimizing your operational costs.

Mistake #6: Relying on incomplete and outdated information

It’s not uncommon to find businesses with little to no data capture to support meaningful physical asset performance analysis. Even if systems do exist, they are often paper-based, requiring correct and diligent completion, manual engineering analysis, and careful storage.

Without a digital system to track asset information and organize maintenance work, asset managers have no other option than to make decisions based on incomplete and outdated information.

Solution: Use physical asset management software like Limble CMMS

From the mistakes and challenges we discussed so far, it’s clear that having the right data at our fingertips would help solve many of our problems. Data provides the input for reliable asset monitoring, analysis, and timely intervention. With the sophistication of modern equipment, we rely on data heavily.

As a centralized digital platform for physical asset management and maintenance, CMMS functions as a knowledge base that enables you to create recurring maintenance reports or pull any data you need in a matter of seconds, helping you make informed decisions that will not bite you in the ass a couple of months later.

A CMMS can predict deterioration, prolong asset life, and automatically manage inventory control and stock levels using artificial intelligence and machine learning algorithms linked to asset-mounted sensors.

Allowing accurate asset tracking and near real-time cost of maintenance interventions, you can perform timely asset maintenance, guide purchase decisions, and optimize your day-to-day tasks. Simply put, you can successfully juggle your limited physical asset management resources.

Physical asset management has to see the big picture

Physical asset management is not a tactic, a system, or a procedure. It’s a strategic way of thinking holistically about a business and reflecting on sustained and optimal asset performance benefits. It requires us to consider each business decision based on its lifetime value, not just its short-term implications.

To achieve the lowest possible total cost of ownership, develop data-driven long-term funding strategies, minimize capital spending, and optimize asset efficiency and ROI, audit your maintenance department – and your asset management software – and make sure you avoid these mistakes.

For more insight on how Limble CMMS can help manage your physical assets, schedule a demo or start a 30-day free trial.