Industrial Maintenance

Everything you ever needed to know about industrial maintenance.

What is industrial maintenance?

Industrial maintenance is the process of ensuring machinery, equipment, and facilities in industrial settings are kept in good working condition to maximize their efficiency, reliability, and lifespan. “Industrial maintenance” is often used interchangeably with the term plant maintenance.

In addition to making sure equipment is performing well, there is another component to industrial maintenance – controlling costs.

Maintaining assets well is essential for hitting production quotas and ensuring high quality. However, it is important to keep maintenance costs low in order to maximize the profits from the products the equipment creates.

The best way to keep maintenance costs in check while still providing quality maintenance services is to set maintenance KPIs and implement the right (mix of) maintenance strategies supported by mobile CMMS apps.

Driving all of that, of course, is talented workers filling essential maintenance roles.

Table of Contents

Most common industrial maintenance jobs

Industrial maintenance training

Industries that heavily rely on industrial maintenance

Maintenance strategies used in industrial maintenance

Four best practices for improving industrial maintenance

Industrial maintenance news and resources

The future of industrial maintenance

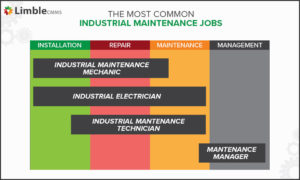

Most common industrial maintenance jobs

Dozens of unique job positions exist in the industrial maintenance field. Some basic qualifications you might encounter with any career in this field include:

- Being good with your hands

- The ability to follow instructions and safety procedures

- Willingness to occasionally work overtime

- Basic computer skills to work with a work order system or CMMS

Beyond these basic skills, industrial maintenance professionals have a wide range of skills to develop, depending on the position they hold.

Here’s a list of the most common industrial maintenance jobs.

Industrial maintenance mechanic

Industrial maintenance mechanics work on installing, repairing, and maintaining industrial equipment. This entry-level role usually only requires a high school education. You can work as an apprentice or assistant with skilled mechanics at the start of your career.

The typical duties of industrial maintenance mechanics are:

- Performing preventative maintenance on all equipment and mechanical systems

- Performing mechanical and electrical troubleshooting and repairs

- Performing hydraulic and pneumatic troubleshooting and repairs

- Installation of new equipment

- Welding and metal fabrication of parts in need of repair

- Machine disassembly and adjustment of machine parts in control instruments

Industrial maintenance technician

Maintenance technicians usually have more training for specific applications than maintenance mechanics. Technicians are highly specialized in certain areas. Their work generally focuses on one type of industry/equipment, making them the “expert” in solving complex issues in one particular area.

An industrial maintenance technician’s job can include:

- Performing preventative maintenance on all facility equipment

- Completing work orders on time while maintaining high-quality standards

- Being readily available for emergency repairs in breakdown situations and potential on-call situations

- Blueprint reading, analyzing, and interpreting technical procedures, electrical schematics, and service manuals

- Troubleshooting mechanical breakdowns

Industrial electrician

Industrial electricians oversee the installation, repair, and maintenance of electrical systems in the industrial setting. They perform many of the same responsibilities as maintenance mechanics and technicians, but they focus primarily on electrical systems.

They are usually responsible for:

- Installing new electrical systems

- Updating, verifying, and maintaining electrical schematics

- Troubleshooting problems with electrical equipment

- Performing repairs and maintenance on existing equipment

Maintenance managers

Maintenance managers focus more on managing people and maintenance operations than on the equipment itself.

Depending on the size of the maintenance department, a maintenance manager’s job can be split into three positions:

- Maintenance manager

- Maintenance planner

- Maintenance supervisor

In smaller facilities, however, a maintenance manager will cover each of these roles.

The responsibilities of a maintenance manager include:

- Scheduling all maintenance-related work by coordinating their maintenance team

- Ensuring that all maintenance operations follow company policy and OSHA guidelines

- Ensuring the facility satisfies all industry regulations

- Managing maintenance budgets

- Forecasting, ordering, and price negotiation for spare parts inventory

- Developing and implementing a proactive maintenance program

- Hiring subcontractors for specialized maintenance work

- Looking for new ways/tools/assets to improve productivity and cut costs

Managerial positions are usually offered to those with a few years of experience. Their range of responsibilities is more consistent across all industries.

Industrial maintenance training

Although it varies from industry to industry, industrial facilities are home to many different assets. This is why an excellent industrial maintenance worker needs a relatively broad range of skills, from servicing hydraulics to welding and precision machining.

That being said, no one is an expert in everything.

Every large industrial facility will have some highly specialized assets, where companies hire outside contractors to perform specific repairs. Their services are in high demand but are also often quite expensive. This further incentivizes businesses to send their technicians for additional maintenance training to perform those repairs in-house.

To provide a better idea of the fundamentals of industrial maintenance training, here’s a short video from Madison College that showcases their industrial maintenance training program:

At some point, all mechanics and technicians undergo an apprenticeship program for hands-on training. Apprenticeships are not hard to find as industrial maintenance jobs are constantly in demand. Apprenticeships help trainees get familiar with the industry they are likely to operate in and give invaluable practical experience.

Industries that heavily rely on industrial maintenance

Industrial equipment is a broad term that encompasses a variety of assets, from ball bearings and air tools, compressors, and valves to bulldozers and cement mixers.

Knowing this makes it easier to identify industrial maintenance just about anywhere. However, certain industries rely on it much more than others, such as:

- Manufacturing industry

- Energy industry (oil, gas, mining, electric power industry)

- Construction industry

- Aviation industry

- Automotive industry

It is interesting to note two things these industries have in common:

- They all work with heavy equipment that incurs significant capital expenditures.

- Maintenance costs make up a large chunk of their operational budget. In simpler terms, they spend a lot of money on asset maintenance.

Checklist for Creating a Preventive Maintenance Plan

Following a consistent Preventive Maintenance Plan can make life easier. Use this checklist to create your own!

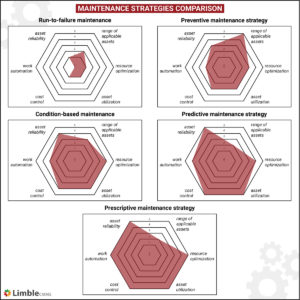

Maintenance strategies used in industrial maintenance

Generally, the best approach is to apply a mix of maintenance strategies. Each company will decide which approach is best, depending on their:

- Assets (their failure modes and maintenance requirements)

- Internal resources (budget, skills, access to tools and technology)

- Maintenance strategies (how they work, their pros and cons, implementation costs and requirements)

Let’s discuss the five maintenance strategies companies use in industrial maintenance.

1) Preventive maintenance

Preventive maintenance is the best way to avoid problems before they happen. After all, “An ounce of prevention is worth a pound of cure.”

It’s almost always the most cost-effective approach to invest in regular maintenance rather than waiting for your equipment to break down. Imagine how much downtime (and money!) a company could save by beating breakdowns to the punch.

2) Run-to-failure maintenance

Though usually not ideal, run-to-failure maintenance can be OK, depending on how it’s used. Since repairs are not planned with a run-to-failure strategy (also referred to as a reactive maintenance strategy), it’s a good method to use on equipment that is not essential for operations or has a low cost.

For example, think of a $1,000 belt feeder whose lifetime value can be extended 10% by servicing it every three months. How hard are you willing to work to save $100? For a non-critical piece of machinery, the answer should be “not hard.”

3) Condition-based maintenance (CBM)

Condition-based maintenance helps determine the right time to perform maintenance activities based on an asset’s current condition. It uses vibration analysis, ultrasonic testing, infrared testing, and other non-destructive testing methods to assess the real-time state of a piece of equipment.

Instead of following fixed maintenance schedules, maintenance managers can rely on condition monitoring data and the P-F intervals to schedule work based on the asset’s current condition.

4) Predictive maintenance (PdM)

Predictive maintenance is one step ahead of CBM. It uses condition monitoring data and combines it with historical data on asset maintenance and performance to create predictive algorithms.

These data models can pinpoint when an asset is likely to fail. With that information, optimizing internal resources (from labor to inventory) and scheduling work right when it is actually needed becomes WAY simpler.

5) Prescriptive maintenance (RxM)

Prescriptive Maintenance is the most tech-fueled approach to asset maintenance.

Prescriptive maintenance relies on machine learning and artificial intelligence to build prescriptive algorithms. These algorithms not only predict failure – they offer potential solutions for the potential problems they identified.

For a more detailed comparison, check out this guide on how to select the right maintenance strategy.

Four best practices for improving industrial maintenance

Industrial maintenance deals with a lot of moving parts, both literally and figuratively. Companies should focus on four actionable tips to maximize the positive effects of their maintenance strategy.

1) Run a proactive maintenance program

There’s a time and a place for almost any maintenance strategy in the industrial maintenance field, but proactive maintenance is where you’ll get the most bang for your buck.

Companies can’t improve results if most of their maintenance activities revolve around fixing things that are already broken. The best place to start is to choose one (or a combination) of proactive maintenance strategies.

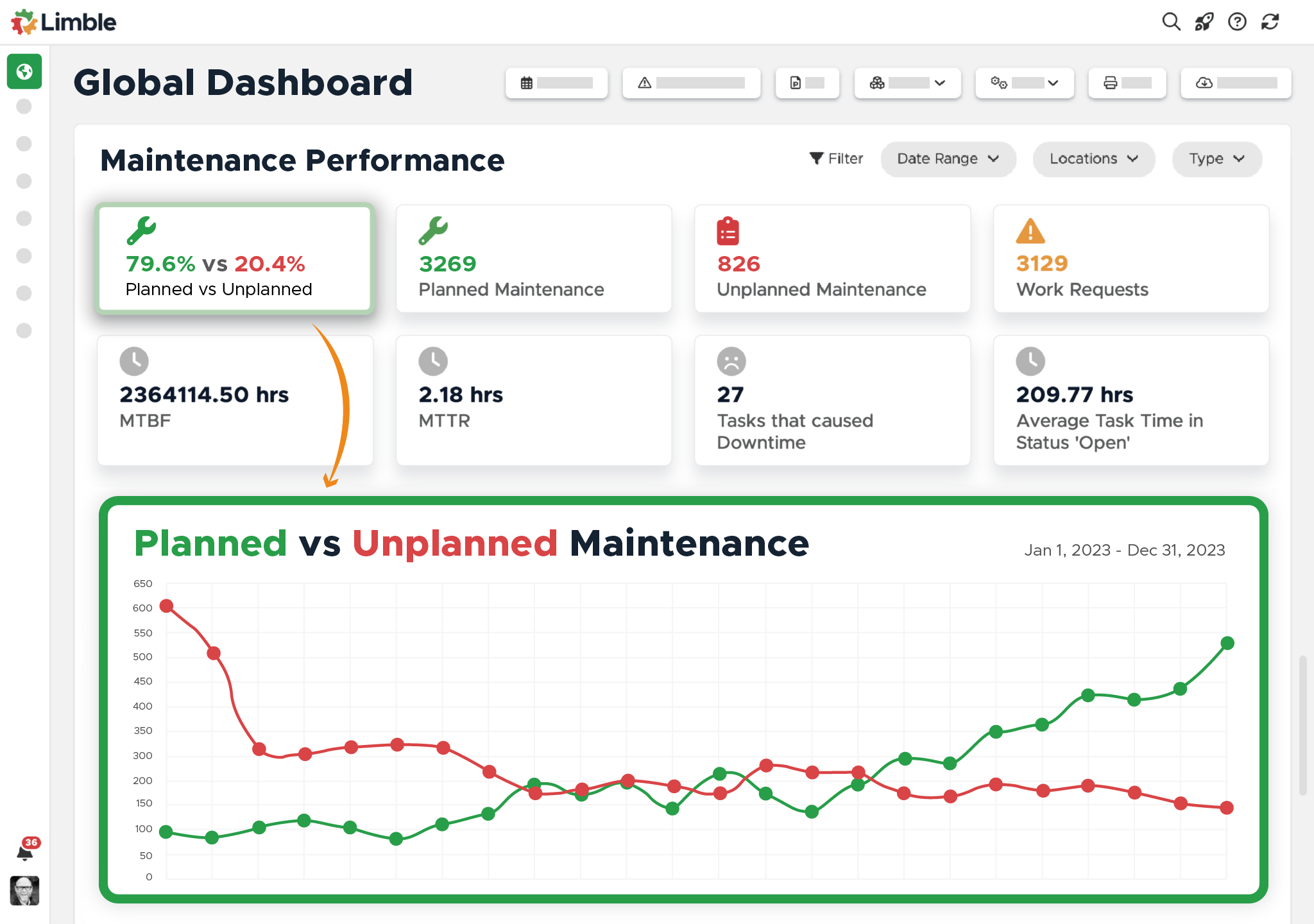

2) Employ mobile maintenance software

It is nearly impossible to run an efficient maintenance department without the support of mobile CMMS.

With the right CMMS, industrial organizations can:

- Manage work. Remotely schedule and track all the work technicians do without having to check on them constantly. It all lives in the CMMS, which management and employees can easily access from their phones.

- Manage spare parts inventory. Know when parts are removed, replaced, or running low with customized alerts.

- Log asset history. Store accurate information on everything, including maintenance and repairs, user manuals, checklists and images, asset health metrics, and task and time management. Use this information to keep industrial machinery in tip-top shape.

- Collect accurate data for work requests and work orders. Instead of writing down or remembering what needs to be done, technicians can use a mobile app to see the information in real-time, document everything, and get the job done right while on location.

- Generate powerful custom maintenance reports. Inform maintenance decisions by collecting accurate, powerful data. Track how much things cost to maintain, how much time is spent on repair, and when an asset is expected to be back online through documentation and data collection.

- Customize everything. From alerts on tasks, spending, and inventory to uploading photos and step-by-step instructions for technicians, the right CMMS is flexible and can be customized to fit any company’s unique use case.

For those who want to learn more about CMMS, here is a one-stop guide about CMMS software: What is a CMMS

3) Define clear procedures

To have a well-oiled industrial maintenance program, a maintenance team needs to know when to do something and how to do it.

To ensure the whole team is on the same page, companies should develop the following documentation:

- Standard operating procedures (SOPs)

- Emergency operating systems (EOPs)

- Preventive maintenance checklists

- OSHA guidelines (Lockout-Tagout procedures, PPE, process safety management, etc.)

Keep in mind, while these procedures can help, they can’t compensate for a lack of training and experience. They should be paired together.

4) Set, measure, improve

Feeling things are going better is not the same as knowing things are better. Setting goals is the only way to ensure continuous improvement. But if companies aren’t tracking progress on those goals, the goals won’t do much good.

To fine-tune industrial maintenance activities, an organization needs to define maintenance KPIs, use a CMMS to track metrics, generate reports, and make changes if the numbers show that they will not hit their maintenance goals.

A good CMMS automatically tracks many maintenance KPIs like MTTR, MTBF, machine uptime, asset utilization, and more.

Simply by completing thorough work orders, a CMMS can put data into easy-to-read automatic reports that businesses can use to improve efficiency (or brag to the people upstairs about how effective their teams are).

Industrial maintenance news and resources

As an organization grows, it should always keep up with best practices and the most innovative processes.

Check out these links and stay in the loop with how the game is changing; new industrial maintenance technology, regulations, statistics, and business development strategies:

- Plant Services: Customize your reading library with up-to-date industrial news, special reports, and case studies.

- Manufacturing.net: Educational content that focuses on aerospace, energy, automotive, and industrial operations.

- Reliability FM: Professional development podcasts that feature the leading experts and innovators of the maintenance world. These podcasts offer learning from the combined knowledge of your peers and masters in the field. Find solutions to the many daily and career challenges you face as a maintenance professional.

- Limble CMMS blog: We feature many great pieces on industrial maintenance and facility management on our blog. Our content team is hard at work every month, and we’re not going to be humble about it.

Want to see Limble in action? Get started for free today!

The future of industrial maintenance

Industrial maintenance professionals have the luck (or misfortune) of working in a dynamic field that is changing quickly due to the impacts of predictive analytics, automation, Industry 4.0, 5G, and other related technology.

That being said, industrial maintenance workers should not yet fear technology, AI robotics, and automation. These jobs are here to stay.

While the tools used to monitor and repair assets might change, and though the assets themselves might change, we are still far from assets becoming autonomous. Even as systems become more automated, we’ll always need talented professionals as an integral part of the maintenance process.

For those looking to jump-start their maintenance efforts with a CMMS, use our contact form to find out how we can help. Alternatively, you can schedule a demo or go for our free trial.