Behind every business success story, there is a maintenance team working behind the scenes to ensure all business operations and activities flow smoothly.

Like any other business function, the maintenance department has many moving parts. Getting all of them to work in sync is a daily grind – even more so if the department is underfunded and under-resourced.

Be that as it may, to organize an efficient maintenance department you need to know the purpose of maintenance at your organization, how to define smart goals, and how to set up your maintenance team for success.

What is the main purpose of a maintenance department?

At face value, every maintenance department’s main purpose is simple: ensure optimal asset reliability and performance.

Improved asset reliability means that an asset is more likely to work without failure for a certain period of time, under set conditions. A reliable asset is like a reliable friend – it will rarely fail you.

But we can do better. A more nuanced definition could say that the main goal of a maintenance department is to ensure asset reliability in a way that aligns with the company’s needs and business goals.

Why is that a better definition?

Well, simply stating that you want to keep assets in peak operating condition forgets about all of the limiting factors like budget, staffing issues, and time constraints.

If your business needs to produce 10 000 canned bottles a day and 60 000 bottles a week, you cannot schedule maintenance for any machine whenever you feel like it. You have to plan downtime for the maintenance of critical assets around the production goals. In other words, your maintenance goals should not prevent you from achieving your production goals, and ultimately your business goals.

Of course, production and business goals can be unrealistic and unreachable with the available resources, but that is a whole other discussion we will leave for another day.

While the overarching goals stay the same, the secondary focus of the maintenance department can change depending on the nature of the business in question. For example, while an industrial maintenance team might be focused on reducing downtime, a building maintenance team might place extra focus on energy efficiency.

In a broader sense, the responsibilities of a maintenance department include:

- Prevent unexpected machine breakdowns

- Maximize the availability and reliability of all operating systems

- Keep equipment and operating systems healthy to eliminate potential safety issues and ensure high operational standards

- Work with production teams to reach production goals

- Support the efforts of other departments

- Provide quality maintenance services while keeping costs under control

- Providing timely and quality maintenance and repair services while keeping costs under control

Setting up a qualified maintenance team

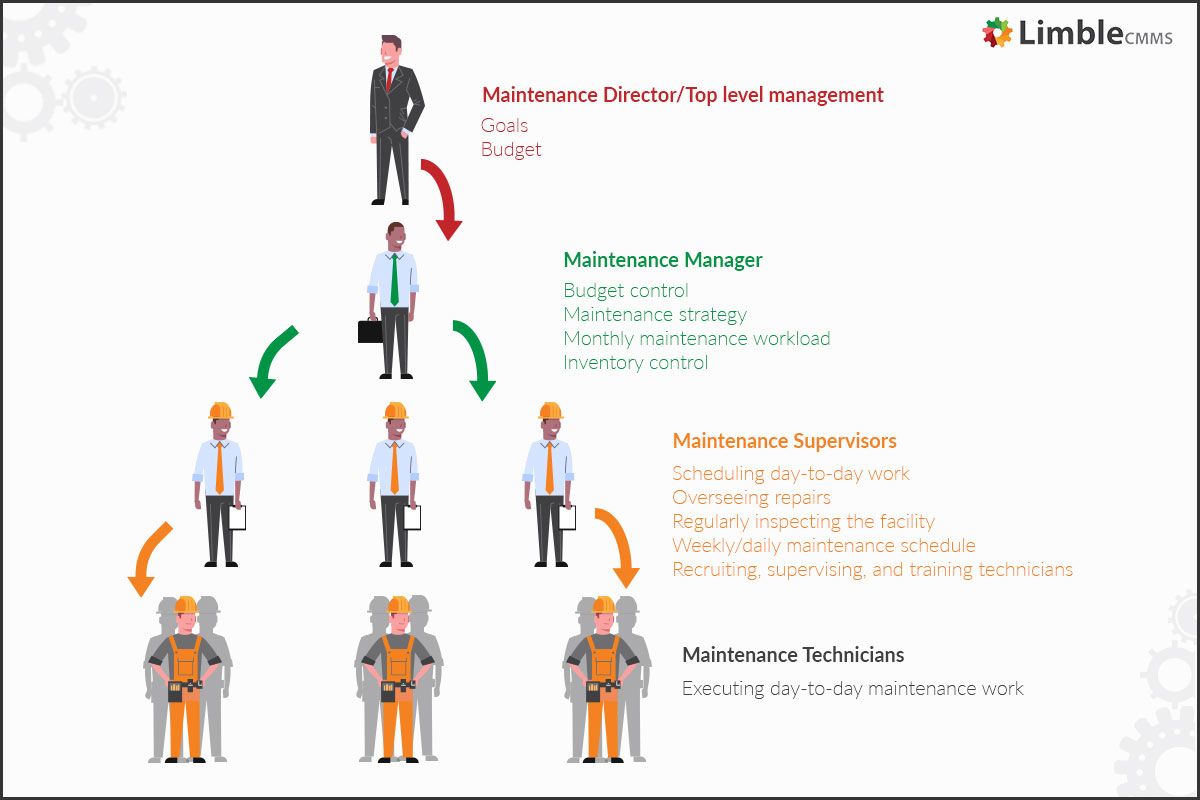

The exact composition of any maintenance team will differ depending on the size of the organization and the amount of maintenance work that needs to be performed. A standard composition for a medium-sized maintenance department looks something like this:

If the number of technicians is in single digits, there is often no need for a middle-man, so the maintenance manager will also take on the responsibilities of a maintenance supervisor.

You can take the list of responsibilities from the picture above with a grain of salt as the exact division of work and duties varies from organization to organization. That becomes obvious as soon as you google job posts for different maintenance roles and compare the list of stated responsibilities.

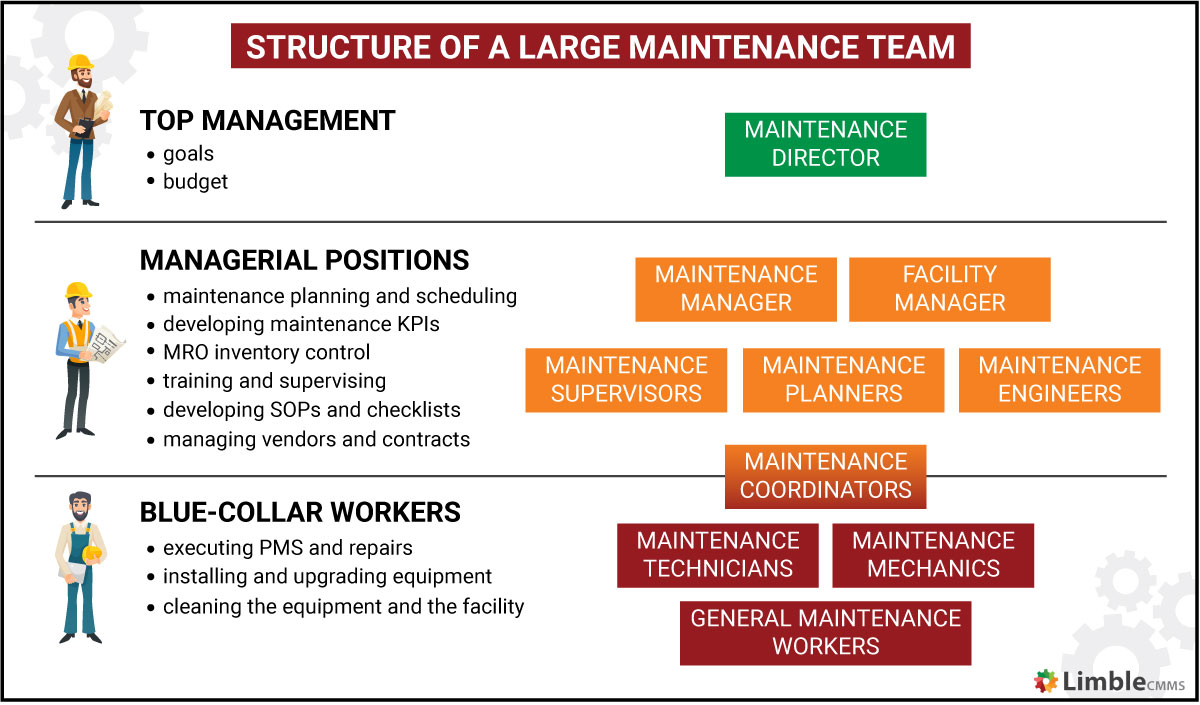

Enterprise-level organizations, especially those in the manufacturing sector, will have to fill out additional maintenance positions to keep things moving smoothly. Below is an extensive list of different maintenance roles with links to respective guides, using a top-down approach:

- Maintenance director

- Maintenance manager

- Maintenance planner

- Maintenance supervisor

- Maintenance engineer

- Maintenance coordinator

- Maintenance technician

- Maintenance mechanic

- General maintenance worker

To help you visualize the difference between the roles and their relative position in the organization, take a look at the graphic below.

Again, keep in mind that the exact day-to-day responsibilities are not set in stone. There is always going to be some crossover of duties and responsibilities, depending on the exact structure of the maintenance team and the available talent.

While everybody’s opinion doesn’t hold the same value when it comes to decision-making, each and every position is an important part of the maintenance team that keeps the gears turning.

Checklist for Creating a Preventive Maintenance Plan

Following a consistent Preventive Maintenance Plan can make life easier. Use this checklist to create your own!

Characteristics of a modern maintenance department

With job structure out of the way, let’s take a look at the characteristics of a modern maintenance department:

- Runs a proactive maintenance program

- Uses modern maintenance techniques (i.e. condition monitoring equipment)

- Supports maintenance efforts with modern software solutions (mobile CMMS, energy management system, predictive analytics, inventory management software…)

- Has a properly trained maintenance team

- Recognizes and adopts industry best practices

- Has a clear line of communication with other departments

- Strives to establish lean maintenance practices

- Sets smart goals to work towards

Many maintenance departments do not have the budget to implement modern tools and techniques. However, one thing every maintenance team should strive for is to be proactive and do more preventive work than reactive work.

How to set smart goals for your maintenance department

You have probably heard about the acronym S.M.A.R.T. It refers to the way in which you should structure your goals.

Let’s look at how this framework applies to defining goals for maintenance:

- Specific: Maintenance goals should be well-defined and clear. Everyone knows the who, what, where, when, and why of the goal.

- Measurable: Each goal should come with specific criteria to measure progress towards accomplishing the goal. Ideally, you should be able to assign one or more maintenance metrics (which you can track) to every maintenance goal you define.

- Achievable: The goal is attainable. It is challenging enough to keep you motivated, but not impossible to achieve.

- Realistic: It can be realized within the allocated time and with the available budget and staff.

- Timely: Has a clearly defined timeline to create a sense of urgency. This is non-negotiable for success as having goals with no due dates is just a wishlist.

For a more detailed breakdown of the relationship between maintenance goals and maintenance metrics, I highly recommend you read our guide for defining maintenance KPIs.

The Essential Guide to CMMS

Download this helpful guide to everything a CMMS has to offer.

How to organize a maintenance department to maximize productivity

There are a few things you can do that will go a long way in helping you establish an efficient maintenance department. We will discuss five of them that stand out the most.

#1) Hire smartly

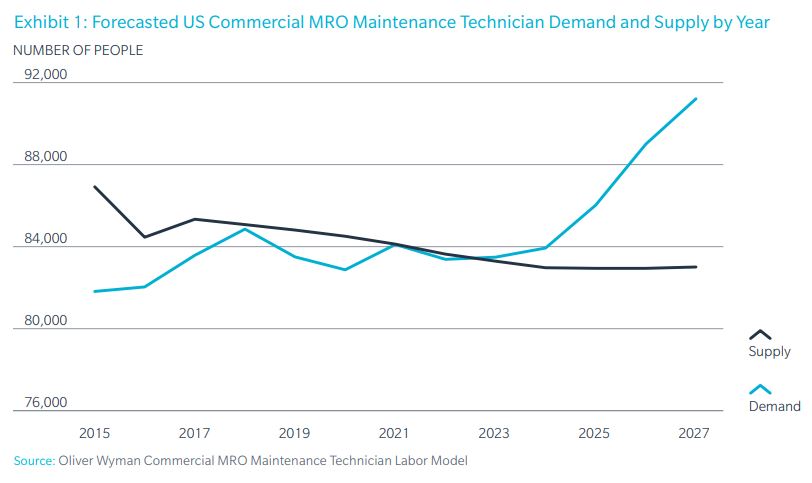

As the aging workforce retires, there are many indications that the maintenance space will have a serious labor shortage. This was one of the four key questions raised at MRO Europe 2018, it is predicted by Oliver Wyman’s MRO survey from 2017 you can see below, and it was confirmed by our 2021. maintenance report.

While the supply and demand predictions need to be corrected to account for the changes in the market caused by COVID-19, the fact is that young people entering the job market are increasingly less interested in blue-collar jobs than previous generations.

For organizations that plan to increase their maintenance departments’ size, this is an important fact to keep in mind. Failure to hire qualified people results in increased overtime and outsourcing, both of which increase operational costs.

When an organization does eventually decide to hire new maintenance professionals, new hires’ character should not be overlooked.

In a few conversations I had with maintenance technicians over the years, it was obvious that there are two types of colleagues they dislike working with the most: the lazy ones and the ones that refuse to learn.

In most cases, you will have two or more technicians working together in a shift. Being a maintenance technician is a physical job, and if someone likes to rest more than they like to work, that slack will have to be picked up either by other workers in their shift or by someone from the following shift.

Similarly, there are stubborn workers that like to do things in their own way, which can be far from optimal. Additionally, they often do not like to put much effort into learning specific machines because they know their range of responsibilities will grow, increasing the workload for other technicians.

So, if you have that luxury, it pays to evaluate the character of potential new hires and provide them a clear path to improve and climb the organizational ladder.

If you’re looking for a place to start, you can try to use the general job posting sites or industry-specific job boards.

Larger organizations should consider partnering with local universities and look for other ways to organize internships and mentorships programs to attract new talent.

#2) Set a clear hierarchy and communication lines

It is hard to have a productive environment if people do not know to whom they can turn to for specific issues, who is in charge, and what is expected of them.

If these things are loosely defined, you will have cases where a new technician has to interrupt three people to solve a certain problem, gets two different answers, and follows the wrong advice.

Establishing a clear hierarchy and ensuring that everyone knows their responsibilities will help to keep things organized.

The importance of clear communication lines can be looked at from two different angles. One would be the importance of smooth information flow through the entire maintenance department that keeps high operational efficiency. The other one is having an open-door policy where the employees can freely share their ideas for improvements or submit complaints.

#3) Standardize important procedures and repetitive tasks

Every organization has its own unique workflow that is defined by how work requests (tickets) are submitted, which maintenance strategy is used, which tools and equipment are available, are they using a CMMS software or not, which communication channels are used, and so on.

Even when an experienced technician comes into the firm, they will need some time to adjust to the new workflow and standard practices.

One way to make this transition smoother is through proper onboarding and training, as well as by:

- Setting up O&M manuals

- Developing standard maintenance operating procedures

- Outlining EHS guidelines

- Writing preventive maintenance checklists

#4) Manage work and inventory with a CMMS

You can’t have a modern maintenance department without a modern CMMS. There are simply too many things that it automates and improves.

In short, a computerized maintenance management system allows you to:

- Plan and oversee all maintenance tasks

- Quickly create and (re)assign any work order based on priority and available resources

- Optimize the work around different maintenance strategies

- Create balanced and efficient maintenance schedules

- Track the usage of spare parts and automatically forecast its demand

- Quickly access detailed asset information from wherever there is internet access

- And many more

CMMS solutions are not particularly expensive, are easier to implement now than they have ever been, and provide a quick ROI. In other words, there are very few valid arguments against implementing it. Here is just one of our many customer testimonials that show these are not empty words:

After about a month of using Limble, we could start to see our maintenance trends on the graphs. Additional P.M.’s were created to counter the trends, and we actually witnessed a drop in our downtime. After using Limble for over a year, I can say that it is paying for itself and worth every implementation area.

– Ben Jackson, Maintenance Manager, Little Giant Ladder Systems

To read more about CMMS check out our What is a CMMS System and How Does it Work guide.

#5) Keep the maintenance team motivated and engaged

Did you ever wonder what is the cost of disengaged workers? Here’s an excerpt from a Forbes article that shows why you need to start thinking about it:

According to Gallup, disengaged employees have 37% higher absenteeism, 18% lower productivity, and 15% lower profitability. When that translates into dollars, you’re looking at the cost of 34% of a disengaged employee’s annual salary, or $3,400 for every $10,000 they make.

A few tips to motivate and engage your maintenance team members:

- provide adequate compensation

- add bonuses and other perks for workers that stand out

- provide an enabling and safe work environment

- offer training and ensure a path for growth

- whenever possible, involve the team in the decision-making process

- try to create an organized and proactive department to minimize frustration due to lack of tools and parts and excessive overtime work

- show gratitude for well-performed work; say thanks when everything is running well

Lastly, make sure the managers in charge of schedules, training, and similar tasks are competent and fair. Workers often leave managers, not organizations.

#6) Commit to continuous improvement

While maintenance is not the most dynamic field out there, this doesn’t mean that you shouldn’t be on the lookout for new technologies, tools, maintenance strategies, best practices, and other ways you can use to improve your maintenance department.

If the budget is tight, that should be another incentive to use a CMMS. Limble, for instance, saves our customers about $20 for every $1 they spend on licensing fees. It does that by helping them spot operational inefficiencies, improve informational flow, control inventory spending, and gather relevant data on productivity and costs of different maintenance actions. They use all of that data to generate helpful reports and gain deeper insights into the causes of different problems.

The easiest way to commit to continuous improvement is to work on spotting and eliminating those problems.

Dream big, start small

Leading a maintenance department is not easy. The good news is that a maintenance department grows alongside the organization it supports, which means that the department head can first build a good foundation and then deal with incoming complexities as the business grows.

With the available software solutions on the market, having a well-organized maintenance department is achievable for almost every organization.

If you have any questions about Limble and how it can support your business, feel free to leave a comment below or get in touch with us via email or phone.

Really a useful post. I work as maintenance engineer of a leading manufacturing company. I always make sure that the maintenance goals do not affect production. Thanks for the tips on setting smart maintenance goals.

Awsome. I own a maintenance company and this article covers pretty much everything. Also a Big fan os Limble cmms

Comments are closed.